Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron - страница 16

Навигация

- L001

- L002

- L003

- L004

- L005

- L006

- L007

- L008

- L009

- L010

- L011

- L012

- L013

- L014

- L015

- L016

- L017

- L018

- L019

- L020

- L021

- L022

- L023

- L024

- L025

- L026

- L027

- L028

- L029

- L030

- L031

- L032

- L033

- L034

- L035

- L036

- L037

- L038

- L039

- L040

- L041

- L042

- L043

- L044

- L045

- L046

- L047

- L048

- L049

- L050

- L051

- L052

- L053

- L054

- L055

- L056

- L057

- L058

- L059

- L060

- L061

- L062

- L063

- L064

- L065

- L066

- L067

- L068

- L069

- L070

- L071

- L072

- L073

- L074

- L075

- L076

- L077

- L078

- L079

- L080

- L081

- L082

- L083

- L084

- L085

- L086

- L087

- L088

- L089

- L090

- L091

- L092

- L093

- L094

- L095

- L096

- L097

- L098

- L099

- L100

- L101

- L102

- L103

- L104

- L105

- L106

- L107

- L108

- L109

- L110

- L111

- L112

- L113

- L114

- L115

- L116

- L117

- L118

- L119

- L120

- L121

- L122

- L123

- L124

- L125

- L126

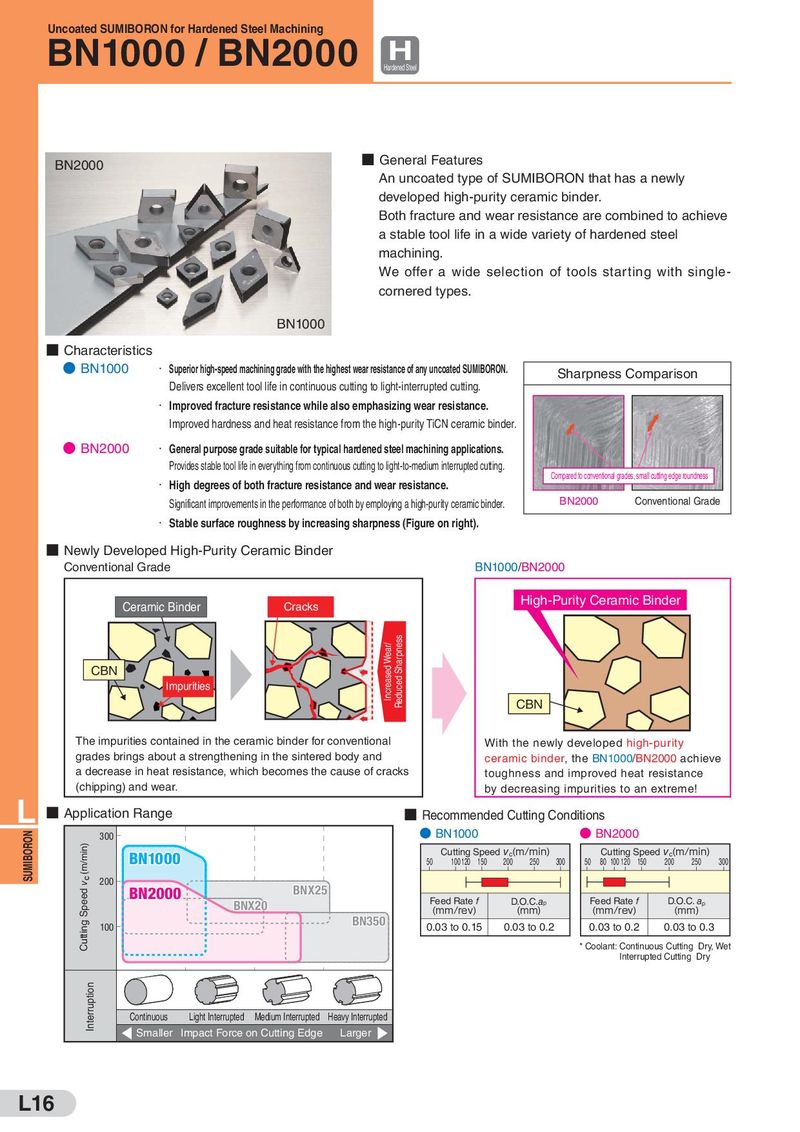

Uncoated SUMIBORON for Hardened Steel Machining B N1000 / BN2000 H Hardened Steel BN2000 ■ General Features An uncoated type of SUMIBORON that has a newly developed high-purity ceramic binder. Both fracture and wear resistance are combined to achieve a stable tool life in a wide variety of hardened steel machining. We offer a wide selection of tools starting with single- cornered types. BN1000 ■ Characteristics ● BN1000 ・ Superior high-speed machining grade with the highest wear resistance of any uncoated SUMIBORON. Sharpness Comparison Delivers excellent tool life in continuous cutting to light-interrupted cutting. ・ Improved fracture resistance while also emphasizing wear resistance. Improved hardness and heat resistance from the high-purity TiCN ceramic binder. ● BN2000 ・ General purpose grade suitable for typical hardened steel machining applications. Provides stable tool life in everything from continuous cutting to light-to-medium interrupted cutting. ・ High degrees of both fracture resistance and wear resistance. Compared to conventional grades, small cutting edge roundness Significant improvements in the performance of both by employing a high-purity ceramic binder. BN2000 Conventional Grade ・ Stable surface roughness by increasing sharpness (Figure on right). ■ Newly Developed High-Purity Ceramic Binder Conventional Grade BN1000/BN2000 Ceramic Binder Cracks High-Purity Ceramic Binder CBN Increased Wear/ Reduced Sharpness Impurities CBN The impurities contained in the ceramic binder for conventional With the newly developed high-purity grades brings about a strengthening in the sintered body and ceramic binder, the BN1000/BN2000 achieve a decrease in heat resistance, which becomes the cause of cracks toughness and improved heat resistance (chipping) and wear. by decreasing impurities to an extreme! L ■ Application Range ■ Recommended Cutting Conditions SUMIBORON 300 ● BN1000 ● BN2000 Cutting Speed vC (m/min) BN1000 Cutting Speed vc(m/min) Cutting Speed vc(m/min) 50 100120 150 200 250 300 50 80 100 120 150 200 250 300 200 BN2000 BNX25 BNX20 Feed Rate f D.O.C.ap Feed Rate f D.O.C. ap (mm/rev) (mm) (mm/rev) (mm) 100 BN350 0.03 to 0.15 0.03 to 0.2 0.03 to 0.2 0.03 to 0.3 * Coolant: Continuous Cutting Dry, Wet Interrupted Cutting Dry Interruption Continuous Light Interrupted Medium Interrupted Heavy Interrupted Smaller Impact Force on Cutting Edge Larger L16

Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo инструмент для отрезки

Каталог Sumitomo инструмент для отрезки Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal