Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron - страница 73

Навигация

- L001

- L002

- L003

- L004

- L005

- L006

- L007

- L008

- L009

- L010

- L011

- L012

- L013

- L014

- L015

- L016

- L017

- L018

- L019

- L020

- L021

- L022

- L023

- L024

- L025

- L026

- L027

- L028

- L029

- L030

- L031

- L032

- L033

- L034

- L035

- L036

- L037

- L038

- L039

- L040

- L041

- L042

- L043

- L044

- L045

- L046

- L047

- L048

- L049

- L050

- L051

- L052

- L053

- L054

- L055

- L056

- L057

- L058

- L059

- L060

- L061

- L062

- L063

- L064

- L065

- L066

- L067

- L068

- L069

- L070

- L071

- L072

- L073

- L074

- L075

- L076

- L077

- L078

- L079

- L080

- L081

- L082

- L083

- L084

- L085

- L086

- L087

- L088

- L089

- L090

- L091

- L092

- L093

- L094

- L095

- L096

- L097

- L098

- L099

- L100

- L101

- L102

- L103

- L104

- L105

- L106

- L107

- L108

- L109

- L110

- L111

- L112

- L113

- L114

- L115

- L116

- L117

- L118

- L119

- L120

- L121

- L122

- L123

- L124

- L125

- L126

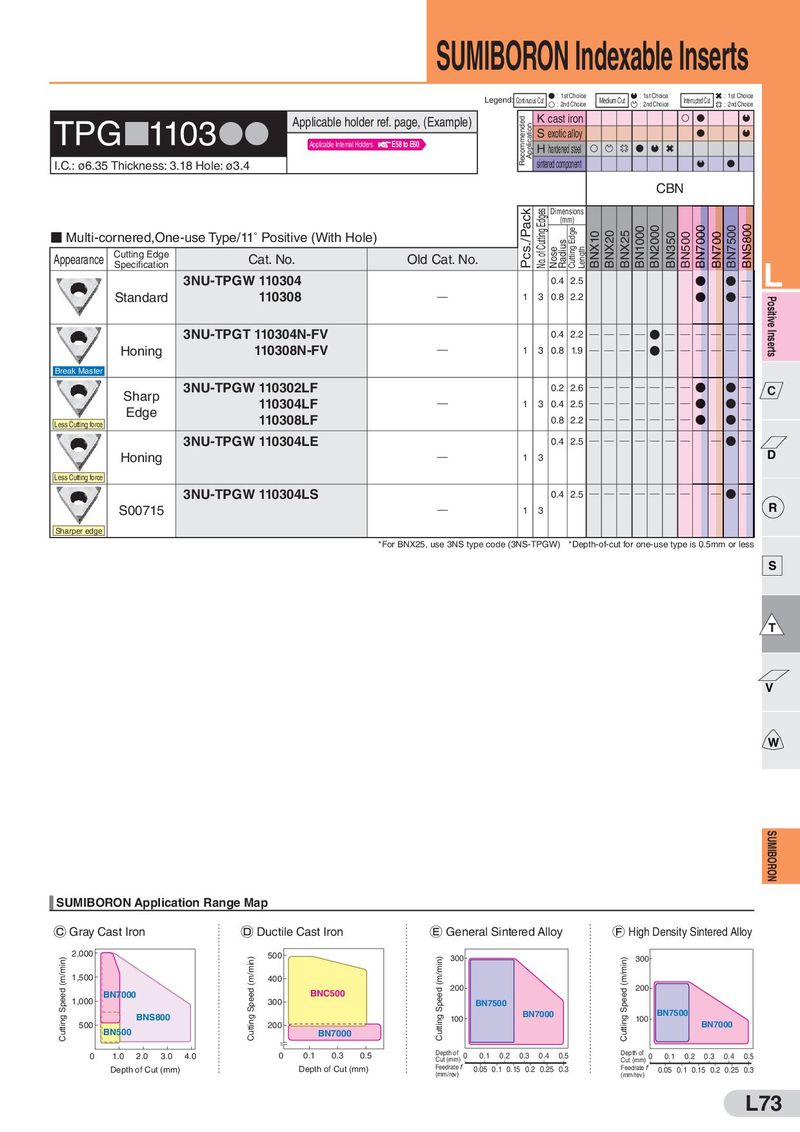

SUMIBORON Indexable Inserts Legend: Continuous Cut : 1st Choice Medium Cut : 1st Choice Interrupted Cut : 1st Choice : 2nd Choice : 2nd Choice : 2nd Choice TPG¢1103 Applicable holder ref. page, (Example) RecommendedApplication K cast iron S exotic alloy Applicable Internal Holders E58 to E60 H hardened steel I.C.: ø6.35 Thickness: 3.18 Hole: ø3.4 sintered component CBN Pcs./Pack No. of Cutting Edges Dimensions (mm) BNS800 ■ Multi-cornered,One-use Type/11°Positive (With Hole) Radius Cutting Edge BNX10 BNX20 BNX25 BN1000 BN2000 BN350 BN500 BN7000 BN700 BN7500 Appearance Cutting Edge Cat. No. Old Cat. No. Nose Length Specification L 3NU-TPGW 110304 0.4 2.5 D DQ Standard 110308 Q 1 3 0.8 2.2 D DQ Positive Inserts 3NU-TPGT 110304N-FV 0.4 2.2 Q Q Q Q D Q Q Q Q Q Q Honing 110308N-FV Q 1 3 0.8 1.9 Q Q Q Q D Q Q Q Q Q Q Break Master Sharp 3NU-TPGW 110302LF 0.2 2.6 Q Q Q Q Q Q Q D D Q C Edge 110304LF Q 1 3 0.4 2.5 Q Q Q Q Q Q Q D D Q Less Cutting force 110308LF 0.8 2.2 Q Q Q Q Q Q Q D D Q 3NU-TPGW 110304LE 0.4 2.5 Q Q Q Q Q Q Q Q D Q Honing Q 1 3 D Less Cutting force 3NU-TPGW 110304LS 0.4 2.5 Q Q Q Q Q Q Q Q D Q S00715 Q 1 3 R Sharper edge *For BNX25, use 3NS type code (3NS-TPGW) *Depth-of-cut for one-use type is 0.5mm or less S T V W SUMIBORON SUMIBORON Application Range Map Ⓒ Gray Cast Iron Ⓓ Ductile Cast Iron Ⓔ General Sintered Alloy Ⓕ High Density Sintered Alloy Cutting Speed (m/min) 2,000 Cutting Speed (m/min) 500 Cutting Speed (m/min) 300 Cutting Speed (m/min) 300 1,500 400 BN7000 BNC500 200 200 1,000 300 BN7500 BNS800 100 BN7000 100 BN7500 500 BN500 200 BN7000 BN7000 0 1.0 2.0 3.0 4.0 0 0.1 0.3 0.5 Depth of 0 0.1 0.2 0.3 0.4 0.5 Depth of 0 0.1 0.2 0.3 0.4 0.5 Cut (mm) Cut (mm) Depth of Cut (mm) Depth of Cut (mm) Feedrate 0.05 0.1 0.15 0.2 0.25 0.3 Feedrate 0.05 0.1 0.15 0.2 0.25 0.3 (mm/rev) (mm/rev) L7733

Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo инструмент для отрезки

Каталог Sumitomo инструмент для отрезки Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal