Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron - страница 114

Навигация

- L001

- L002

- L003

- L004

- L005

- L006

- L007

- L008

- L009

- L010

- L011

- L012

- L013

- L014

- L015

- L016

- L017

- L018

- L019

- L020

- L021

- L022

- L023

- L024

- L025

- L026

- L027

- L028

- L029

- L030

- L031

- L032

- L033

- L034

- L035

- L036

- L037

- L038

- L039

- L040

- L041

- L042

- L043

- L044

- L045

- L046

- L047

- L048

- L049

- L050

- L051

- L052

- L053

- L054

- L055

- L056

- L057

- L058

- L059

- L060

- L061

- L062

- L063

- L064

- L065

- L066

- L067

- L068

- L069

- L070

- L071

- L072

- L073

- L074

- L075

- L076

- L077

- L078

- L079

- L080

- L081

- L082

- L083

- L084

- L085

- L086

- L087

- L088

- L089

- L090

- L091

- L092

- L093

- L094

- L095

- L096

- L097

- L098

- L099

- L100

- L101

- L102

- L103

- L104

- L105

- L106

- L107

- L108

- L109

- L110

- L111

- L112

- L113

- L114

- L115

- L116

- L117

- L118

- L119

- L120

- L121

- L122

- L123

- L124

- L125

- L126

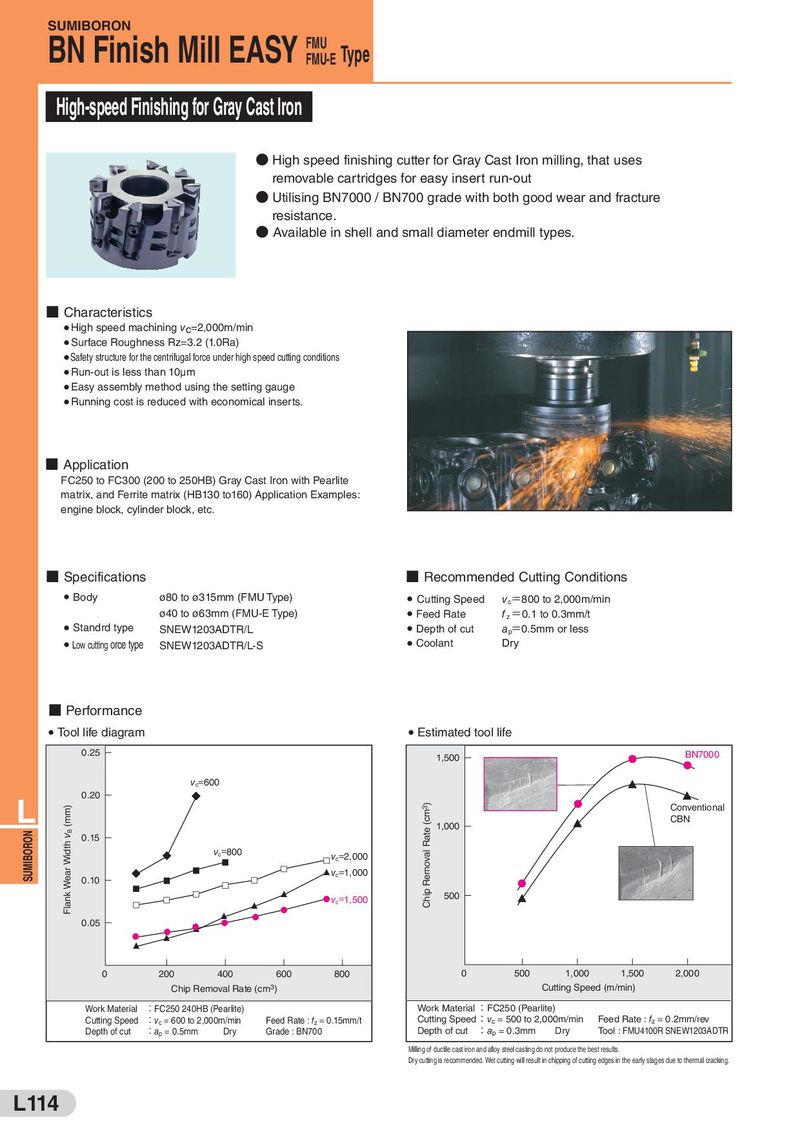

SUMIBORON BN Finish Mill EASY FMU Type FMU-E High-speed Finishing for Gray Cast Iron ● High speed finishing cutter for Gray Cast Iron milling, that uses removable cartridges for easy insert run-out ● Utilising BN7000 / BN700 grade with both good wear and fracture resistance. ● Available in shell and small diameter endmill types. ■ Characteristics ● High speed machining vc=2,000m/min ● Surface Roughness Rz=3.2 (1.0Ra) ● Safety structure for the centrifugal force under high speed cutting conditions ● Run-out is less than 10μm ● Easy assembly method using the setting gauge ● Running cost is reduced with economical inserts. ■ Application FC250 to FC300 (200 to 250HB) Gray Cast Iron with Pearlite matrix, and Ferrite matrix (HB130 to160) Application Examples: engine block, cylinder block, etc. ■ Specifications ■ Recommended Cutting Conditions ● Body ø80 to ø315mm (FMU Type) ● Cutting Speed vc=800 to 2,000m/min ø40 to ø63mm (FMU-E Type) ● Feed Rate f z=0.1 to 0.3mm/t ● Standrd type SNEW1203ADTR/L ● Depth of cut ap=0.5mm or less ● Low cutting orce type SNEW1203ADTR/L-S ● Coolant Dry ■ Performance ● Tool life diagram ● Estimated tool life 0.25 1,500 BN7000 vc=600 L 0.20 B (mm) Chip Removal Rate (cm3) Conventional 1,000 CBN SUMIBORON Flank Wear Width 0.15 vc=800 vc=2,000 0.10 F vc=1,000 F D vc=1,500 500 F D 0.05 F D DF D D D F F 0 200 400 600 800 0 500 1,000 1,500 2,000 Chip Removal Rate (cm3) Cutting Speed (m/min) Work Material :FC250 240HB (Pearlite) Work Material :FC250 (Pearlite) Cutting Speed :vc = 600 to 2,000m/min Feed Rate : fz = 0.15mm/t Cutting Speed:vc = 500 to 2,000m/min Feed Rate : fz = 0.2mm/rev Depth of cut :ap = 0.5mm Dry Grade : BN700 Depth of cut :ap = 0.3mm Dry Tool : FMU4100R SNEW1203ADTR Milling of ductile cast iron and alloy steel casting do not produce the best results. Dry cutting is recommended. Wet cutting will result in chipping of cutting edges in the early stages due to thermal cracking. L114

Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo инструмент для отрезки

Каталог Sumitomo инструмент для отрезки Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal