Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron - страница 125

Навигация

- L001

- L002

- L003

- L004

- L005

- L006

- L007

- L008

- L009

- L010

- L011

- L012

- L013

- L014

- L015

- L016

- L017

- L018

- L019

- L020

- L021

- L022

- L023

- L024

- L025

- L026

- L027

- L028

- L029

- L030

- L031

- L032

- L033

- L034

- L035

- L036

- L037

- L038

- L039

- L040

- L041

- L042

- L043

- L044

- L045

- L046

- L047

- L048

- L049

- L050

- L051

- L052

- L053

- L054

- L055

- L056

- L057

- L058

- L059

- L060

- L061

- L062

- L063

- L064

- L065

- L066

- L067

- L068

- L069

- L070

- L071

- L072

- L073

- L074

- L075

- L076

- L077

- L078

- L079

- L080

- L081

- L082

- L083

- L084

- L085

- L086

- L087

- L088

- L089

- L090

- L091

- L092

- L093

- L094

- L095

- L096

- L097

- L098

- L099

- L100

- L101

- L102

- L103

- L104

- L105

- L106

- L107

- L108

- L109

- L110

- L111

- L112

- L113

- L114

- L115

- L116

- L117

- L118

- L119

- L120

- L121

- L122

- L123

- L124

- L125

- L126

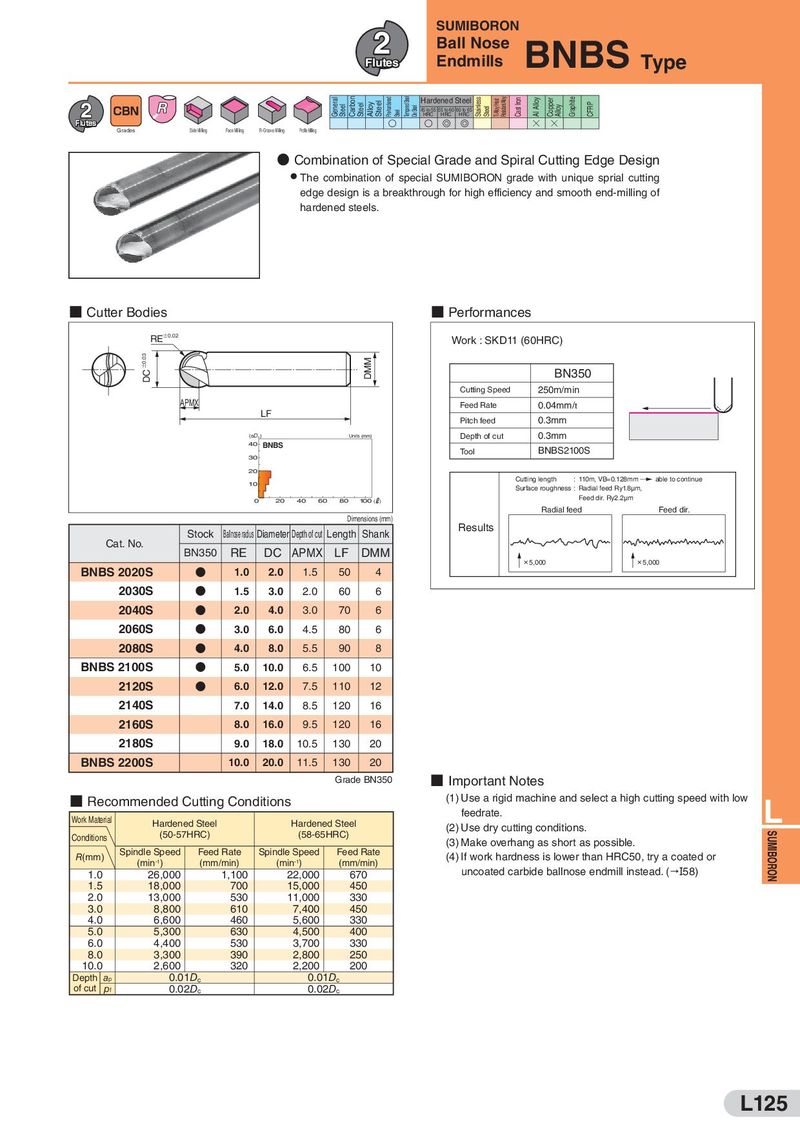

2 SUMIBORON Ball Nose BNBS Flutes Endmills Type 2 General Steel Carbon Steel Alloy Steel Pre-hardened Tempered Steel Hardened Steel Stainless Ti A loy /Heat Resistant A loy Cast Iron Al Alloy Copper Alloy Graphite CFRP Steel Die Steel 45 to 55 55 to 60 60 to 65 Steel HRC HRC HRC Flutes S S G G H H Grades Side Milling Face Milling R-Groove Milling Profile Milling ● Combination of Special Grade and Spiral Cutting Edge Design ● The combination of special SUMIBORON grade with unique sprial cutting edge design is a breakthrough for high efficiency and smooth end-milling of hardened steels. ■ Cutter Bodies ■ Performances RE±0.02 Work : SKD11 (60HRC) DC ±0.03 DMM BN350 Cutting Speed 250m/min APMX Feed Rate 0.04mm/t LF Pitch feed 0.3mm (ø c) Units (mm) Depth of cut 0.3mm 40 BNBS BNBS2100S 30 Tool 20 10 Cutting length : 110m, VB=0.128mm able to continue Surface roughness : Radial feed Ry1.8µm, 0 20 40 60 80 100 ( ) Feed dir. Ry2.2µm Radial feed Feed dir. Dimensions (mm) Stock Balnose radius Diameter Depth of cut Length Shank Results Cat. No. BN350 RE DC APMX LF DMM 5,000 5,000 BNBS 2020S D 1.0 2.0 1.5 50 4 2030S D 1.5 3.0 2.0 60 6 2040S D 2.0 4.0 3.0 70 6 2060S D 3.0 6.0 4.5 80 6 2080S D 4.0 8.0 5.5 90 8 BNBS 2100S D 5.0 10.0 6.5 100 10 2120S D 6.0 12.0 7.5 110 12 2140S 7.0 14.0 8.5 120 16 2160S 8.0 16.0 9.5 120 16 2180S 9.0 18.0 10.5 130 20 BNBS 2200S 10.0 20.0 11.5 130 20 Grade BN350 ■ Important Notes ■ Recommended Cutting Conditions (1) Use a rigid machine and select a high cutting speed with low L Work Material feedrate. Hardened Steel Hardened Steel (2) Use dry cutting conditions. Conditions (50-57HRC) (58-65HRC) (3) Make overhang as short as possible. SUMIBORON R(mm) Spindle Speed Feed Rate Spindle Speed Feed Rate (4) If work hardness is lower than HRC50, try a coated or (min-1) (mm/min) (min-1) (mm/min) uncoated carbide ballnose endmill instead. (¦I58) 1.0 26,000 1,100 22,000 670 1.5 18,000 700 15,000 450 2.0 13,000 530 11,000 330 3.0 8,800 610 7,400 450 4.0 6,600 460 5,600 330 5.0 5,300 630 4,500 400 6.0 4,400 530 3,700 330 8.0 3,300 390 2,800 250 10.0 2,600 320 2,200 200 Depth ap 0.01Dc 0.01Dc of cut pf 0.02Dc 0.02Dc L125

Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo инструмент для отрезки

Каталог Sumitomo инструмент для отрезки Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal