Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron - страница 15

Навигация

- L001

- L002

- L003

- L004

- L005

- L006

- L007

- L008

- L009

- L010

- L011

- L012

- L013

- L014

- L015

- L016

- L017

- L018

- L019

- L020

- L021

- L022

- L023

- L024

- L025

- L026

- L027

- L028

- L029

- L030

- L031

- L032

- L033

- L034

- L035

- L036

- L037

- L038

- L039

- L040

- L041

- L042

- L043

- L044

- L045

- L046

- L047

- L048

- L049

- L050

- L051

- L052

- L053

- L054

- L055

- L056

- L057

- L058

- L059

- L060

- L061

- L062

- L063

- L064

- L065

- L066

- L067

- L068

- L069

- L070

- L071

- L072

- L073

- L074

- L075

- L076

- L077

- L078

- L079

- L080

- L081

- L082

- L083

- L084

- L085

- L086

- L087

- L088

- L089

- L090

- L091

- L092

- L093

- L094

- L095

- L096

- L097

- L098

- L099

- L100

- L101

- L102

- L103

- L104

- L105

- L106

- L107

- L108

- L109

- L110

- L111

- L112

- L113

- L114

- L115

- L116

- L117

- L118

- L119

- L120

- L121

- L122

- L123

- L124

- L125

- L126

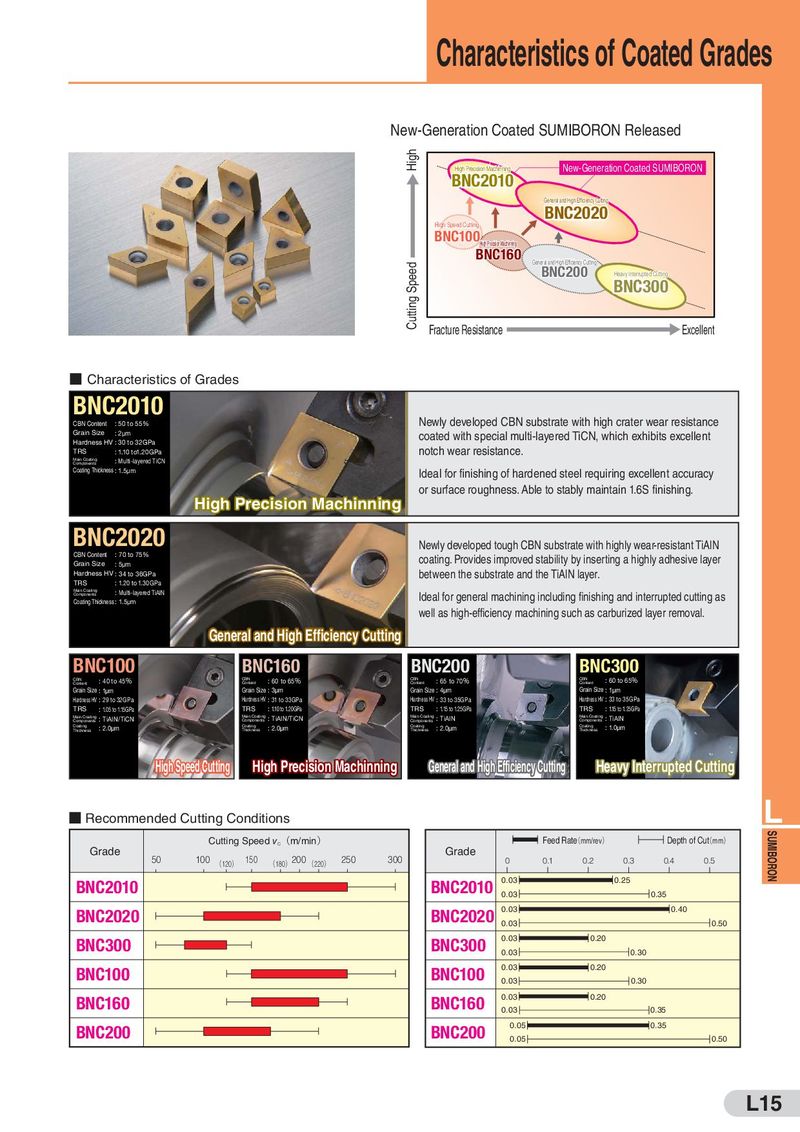

Characteristics of Coated Grades New-Generation Coated SUMIBORON Released High High Precision Machinning New-Generation Coated SUMIBORON BNC2010 General and High Efficiency Cutting BNC2020 High Speed Cutting BNC100 High Precision Machinning BNC160 Cutting Speed General and High Efficiency Cutting BNC200 Heavy Interrupted Cutting BNC300 Fracture Resistance Excellent ■ Characteristics of Grades BNC2010 CBN Content : 50 to 55% Newly developed CBN substrate with high crater wear resistance Grain Size : 2μm coated with special multi-layered TiCN, which exhibits excellent Hardness HV : 30 to 32GPa TRS : 1.10 to1.20GPa notch wear resistance. Main Coating : Multi-layered TiCN Components Coating Thickness : 1.5μm Ideal for finishing of hardened steel requiring excellent accuracy or surface roughness. Able to stably maintain 1.6S finishing. High Precision Machinning BNC2020 Newly developed tough CBN substrate with highly wear-resistant TiAlN CBN Content : 70 to 75% coating. Provides improved stability by inserting a highly adhesive layer Grain Size : 5μm Hardness HV : 34 to 36GPa between the substrate and the TiAlN layer. TRS : 1.20 to 1.30GPa Main Coating : Multi-layered TiAlN Ideal for general machining including finishing and interrupted cutting as Components Coating Thickness : 1.5μm well as high-efficiency machining such as carburized layer removal. General and High Efficiency Cutting BNC100 BNC160 BNC200 BNC300 CBN : 40 to 45% CBN : 60 to 65% CBN : 65 to 70% CBN : 60 to 65% Content Content Content Content Grain Size : 1μm Grain Size : 3μm Grain Size : 4μm Grain Size : 1μm Hardness HV : 29 to 32GPa Hardness HV : 31 to 33GPa Hardness HV : 33 to 35GPa Hardness HV : 33 to 35GPa TRS : 1.05 to 1.15GPa TRS : 1.10 to 1.20GPa TRS : 1.15 to 1.25GPa TRS : 1.15 to 1.25GPa Main Coating : TiAlN/TiCN Main Coating : TiAlN/TiCN Main Coating : TiAlN Main Coating : TiAlN Components Components Components Components Coating : 2.0μm Coating : 2.0μm Coating : 2.0μm Coating : 1.0μm Thickness Thickness Thickness Thickness High Speed Cutting High Precision Machinning General and High Efficiency Cutting Heavy Interrupted Cutting ■ Recommended Cutting Conditions L Cutting Speed vc(m/min) Feed Rate(mm/rev) Depth of Cu(t mm) SUMIBORON Grade 50 100 150 (180) 200 (220) 250 300 Grade (120) 0 0.1 0.2 0.3 0.4 0.5 BNC2010 BNC2010 0.03 0.25 0.03 0.35 BNC2020 BNC2020 0.03 0.40 0.03 0.50 BNC300 BNC300 0.03 0.20 0.03 0.30 BNC100 BNC100 0.03 0.20 0.03 0.30 BNC160 BNC160 0.03 0.20 0.03 0.35 BNC200 BNC200 0.05 0.35 0.05 0.50 L15

Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo инструмент для отрезки

Каталог Sumitomo инструмент для отрезки Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal