Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron - страница 118

Навигация

- L001

- L002

- L003

- L004

- L005

- L006

- L007

- L008

- L009

- L010

- L011

- L012

- L013

- L014

- L015

- L016

- L017

- L018

- L019

- L020

- L021

- L022

- L023

- L024

- L025

- L026

- L027

- L028

- L029

- L030

- L031

- L032

- L033

- L034

- L035

- L036

- L037

- L038

- L039

- L040

- L041

- L042

- L043

- L044

- L045

- L046

- L047

- L048

- L049

- L050

- L051

- L052

- L053

- L054

- L055

- L056

- L057

- L058

- L059

- L060

- L061

- L062

- L063

- L064

- L065

- L066

- L067

- L068

- L069

- L070

- L071

- L072

- L073

- L074

- L075

- L076

- L077

- L078

- L079

- L080

- L081

- L082

- L083

- L084

- L085

- L086

- L087

- L088

- L089

- L090

- L091

- L092

- L093

- L094

- L095

- L096

- L097

- L098

- L099

- L100

- L101

- L102

- L103

- L104

- L105

- L106

- L107

- L108

- L109

- L110

- L111

- L112

- L113

- L114

- L115

- L116

- L117

- L118

- L119

- L120

- L121

- L122

- L123

- L124

- L125

- L126

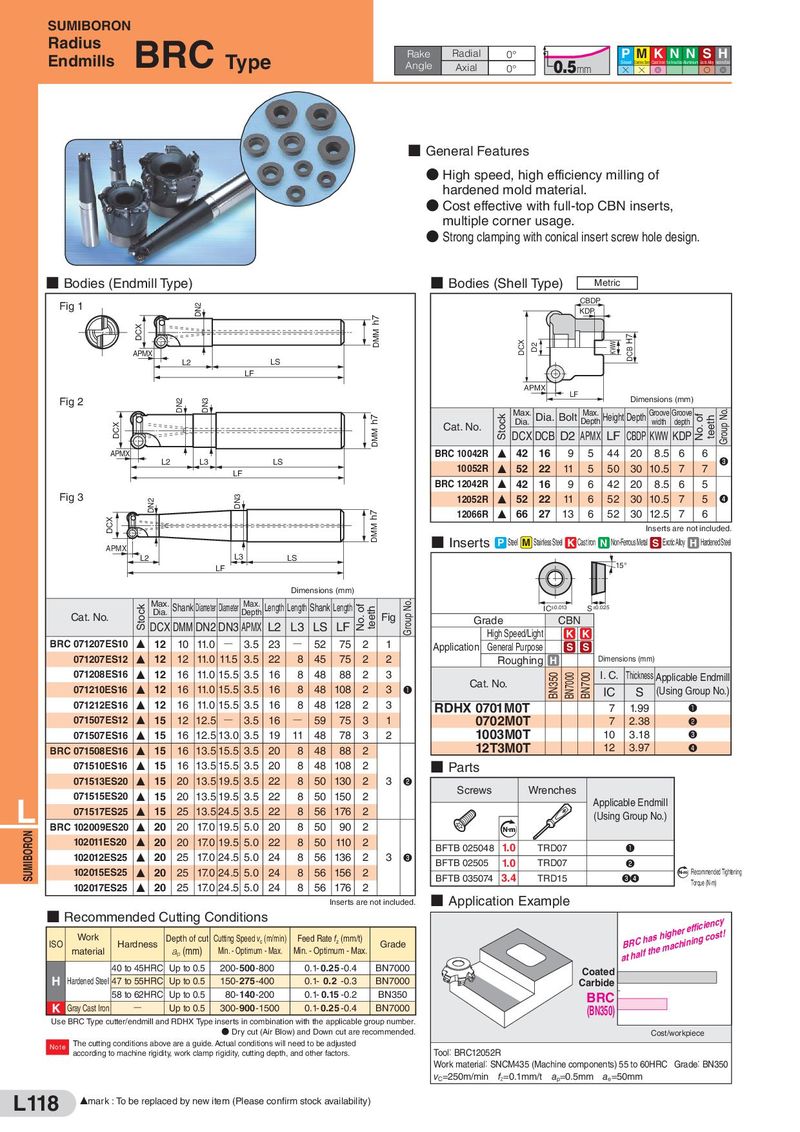

SUMIBORON Radius BRC Rake Radial 0° P M K N N S H Endmills Type Angle Axial 0.5mm Steel Stainless Steel Cast Iron Non-FerrousMetal Aluminium Exotic Alloy HardenedSteel 0° H H G S G ■ General Features ● High speed, high efficiency milling of hardened mold material. ● Cost effective with full-top CBN inserts, multiple corner usage. ● Strong clamping with conical insert screw hole design. ■ Bodies (Endmill Type) ■ Bodies (Shell Type) Metric Fig 1 DN2 CBDP KDP DCX h7 DMM DCX D2 KWW DCB H7 APMX l LS L2 LF APMX LF Fig 2 DN2 DN3 Dimensions (mm) DMM h7 Stock Max. Dia. Bolt Max. Height Depth Groove Groove No. of teeth Group No. DCX Cat. No. Dia. Depth width depth DCX DCB D2 APMX LF CBDP KWW KDP APMX l L2 L3 LS BRC 10042R F 42 16 9 5 44 20 8.5 6 6 ❸ LF 10052R F 52 22 11 5 50 30 10.5 7 7 BRC 12042R F 42 16 9 6 42 20 8.5 6 5 Fig 3 DN2 DN3 12052R F 52 22 11 6 52 30 10.5 7 5 ❹ DCX DMM h7 12066R F 66 27 13 6 52 30 12.5 7 6 Inserts are not included. APMlX ■ Inserts P Steel M Stainless Steel K Cast Iron N Non-Ferrous Metal S Exotic Al oy H Hardened Steel L2 L3 LS LF 15° Dimensions (mm) Stock Max. Shank Diameter Diameter Max. Length Length Shank Length No. of teeth Group No. IC±0.013 S±0.025 Cat. No. Dia. Depth Fig Grade CBN DCX DMM DN2 DN3 APMX L2 L3 LS LF High Speed/Light K K BRC 071207ES10 F 12 10 11.0 Q 3.5 23 Q 52 75 2 1 Application General Purpose S S 071207ES12 F 12 12 11.0 11.5 3.5 22 8 45 75 2 2 Roughing H Dimensions (mm) 071208ES16 F 12 16 11.0 15.5 3.5 16 8 48 88 2 3 Cat. No. BN350 BN7000 BN700 I. C. Thickness Applicable Endmill 071210ES16 F 12 16 11.0 15.5 3.5 16 8 48 108 2 3 ❶ IC S (Using Group No.) 071212ES16 F 12 16 11.0 15.5 3.5 16 8 48 128 2 3 RDHX 0701M0T 7 1.99 ❶ 071507ES12 F 15 12 12.5 Q 3.5 16 Q 59 75 3 1 0702M0T 7 2.38 ❷ 071507ES16 F 15 16 12.5 13.0 3.5 19 11 48 78 3 2 1003M0T 10 3.18 ❸ BRC 071508ES16 F 15 16 13.5 15.5 3.5 20 8 48 88 2 12T3M0T 12 3.97 ❹ 071510ES16 F 15 16 13.5 15.5 3.5 20 8 48 108 2 ■ Parts 071513ES20 F 15 20 13.5 19.5 3.5 22 8 50 130 2 3 ❷ Screws Wrenches L 071515ES20 F 15 20 13.5 19.5 3.5 22 8 50 150 2 Applicable Endmill 071517ES25 F 15 25 13.5 24.5 3.5 22 8 56 176 2 (Using Group No.) SUMIBORON BRC 102009ES20 F 20 20 17.0 19.5 5.0 20 8 50 90 2 Nm 102011ES20 F 20 20 17.0 19.5 5.0 22 8 50 110 2 BFTB 025048 1.0 TRD07 ❶ 102012ES25 F 20 25 17.0 24.5 5.0 24 8 56 136 2 3 ❸ BFTB 02505 1.0 TRD07 ❷ 102015ES25 F 20 25 17.0 24.5 5.0 24 8 56 156 2 BFTB 035074 3.4 TRD15 ❸❹ N m Recommended Tightening 102017ES25 F 20 25 17.0 24.5 5.0 24 8 56 176 2 Torque (N·m) Inserts are not included. ■ Application Example ■ Recommended Cutting Conditions aBtRhCalfhtahsehmigahcehrineifnfigciecnocsyt! ISO Work Hardness Depth of cut Cutting Speed vc (m/min) Feed Rate fz (mm/t) Grade material ap (mm) Min. - Optimum - Max. Min. - Optimum - Max. 40 to 45HRC Up to 0.5 200-500-800 0.1- 0.25 -0.4 BN7000 Coated H Hardened Steel 47 to 55HRC Up to 0.5 150- 275 -400 0.1- 0.2 -0.3 BN7000 Carbide 58 to 62HRC Up to 0.5 80- 140 -200 0.1- 0.15 -0.2 BN350 BRC K Gray Cast Iron Q Up to 0.5 300-900-1500 0.1- 0.25 -0.4 BN7000 (BN350) Use BRC Type cutter/endmill and RDHX Type inserts in combination with the applicable group number. ● Dry cut (Air Blow) and Down cut are recommended. Cost/workpiece Note The cutting conditions above are a guide. Actual conditions will need to be adjusted according to machine rigidity, work clamp rigidity, cutting depth, and other factors. Too:l BRC12052R Work materia:l SNCM435 (Machine components) 55 to 60HRC Grade:BN350 vC=250m/min fz=0.1mm/t ap=0.5mm ae=50mm L118 Fmark : To be replaced by new item (Please confirm stock availability)

Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo инструмент для отрезки

Каталог Sumitomo инструмент для отрезки Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal