Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron - страница 66

Навигация

- L001

- L002

- L003

- L004

- L005

- L006

- L007

- L008

- L009

- L010

- L011

- L012

- L013

- L014

- L015

- L016

- L017

- L018

- L019

- L020

- L021

- L022

- L023

- L024

- L025

- L026

- L027

- L028

- L029

- L030

- L031

- L032

- L033

- L034

- L035

- L036

- L037

- L038

- L039

- L040

- L041

- L042

- L043

- L044

- L045

- L046

- L047

- L048

- L049

- L050

- L051

- L052

- L053

- L054

- L055

- L056

- L057

- L058

- L059

- L060

- L061

- L062

- L063

- L064

- L065

- L066

- L067

- L068

- L069

- L070

- L071

- L072

- L073

- L074

- L075

- L076

- L077

- L078

- L079

- L080

- L081

- L082

- L083

- L084

- L085

- L086

- L087

- L088

- L089

- L090

- L091

- L092

- L093

- L094

- L095

- L096

- L097

- L098

- L099

- L100

- L101

- L102

- L103

- L104

- L105

- L106

- L107

- L108

- L109

- L110

- L111

- L112

- L113

- L114

- L115

- L116

- L117

- L118

- L119

- L120

- L121

- L122

- L123

- L124

- L125

- L126

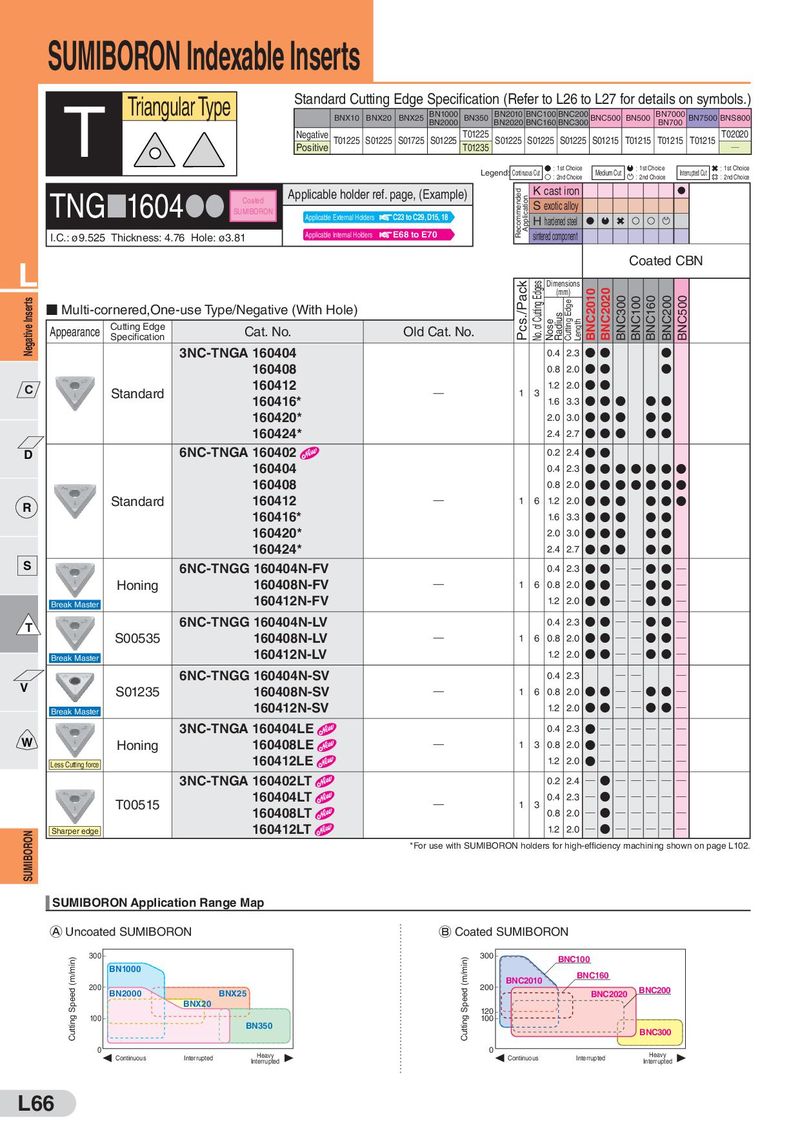

SUMIBORON Indexable Inserts T Triangular Type Standard Cutting Edge Specification (Refer to L26 to L27 for details on symbols.) BNX10 BNX20 BNX25 BN1000 BN350 BN2010 BNC100 BNC200 BNC500 BN500 BN7000 BN7500 BNS800 BN2000 BN2020 BNC160 BNC300 BN700 Negative T01225 S01225 S01725 S01225 T01225 S01225 S01225 S01225 S01215 T01215 T01215 T01215 T02020 Positive T01235 Q Legend: Continuous Cut : 1st Choice Medium Cut : 1st Choice Interrupted Cut : 1st Choice : 2nd Choice : 2nd Choice : 2nd Choice TNG¢1604 Coated Applicable holder ref. page, (Example) RecommendedApplication K cast iron SUMIBORON S exotic alloy Applicable External Holders C23 to C29, D15, 18 H hardened steel I.C.: ø9.525 Thickness: 4.76 Hole: ø3.81 Applicable Internal Holders E68 to E70 sintered component L Coated CBN Pcs./Pack No. of Cutting Edges Dimensions BNC2010 BNC2020 (mm) BNC300 BNC100 BNC160 BNC200 BNC500 Negative Inserts ■ Multi-cornered,One-use Type/Negative (With Hole) Radius Cutting Edge Appearance Cutting Edge Cat. No. Old Cat. No. Nose Length Specification 3NC-TNGA 160404 0.4 2.3 D D D 160408 0.8 2.0 D D D C Standard 160412 Q 1 3 1.2 2.0 D D 160416* 1.6 3.3 D D D D D 160420* 2.0 3.0 D D D D D 160424* 2.4 2.7 D D D D D D 6NC-TNGA 160402 0.2 2.4 D D 160404 0.4 2.3 D D D D D D D 160408 0.8 2.0 D D D D D D D R Standard 160412 Q 1 6 1.2 2.0 D D D D D D 160416* 1.6 3.3 D D D D D 160420* 2.0 3.0 D D D D D 160424* 2.4 2.7 D D D D D S 6NC-TNGG 160404N-FV 0.4 2.3 D D Q Q D D Q Honing 160408N-FV Q 1 6 0.8 2.0 D D Q Q D D Q Break Master 160412N-FV 1.2 2.0 D D Q Q D D Q T 6NC-TNGG 160404N-LV 0.4 2.3 D D Q Q D D Q S00535 160408N-LV Q 1 6 0.8 2.0 D D Q Q D D Q Break Master 160412N-LV 1.2 2.0 D D Q Q D D Q 6NC-TNGG 160404N-SV 0.4 2.3 Q Q Q V S01235 160408N-SV Q 1 6 0.8 2.0 D D Q Q D D Q Break Master 160412N-SV 1.2 2.0 D D Q Q D D Q 3NC-TNGA 160404LE 0.4 2.3 D Q Q Q Q Q Q W Honing 160408LE Q 1 3 0.8 2.0 D Q Q Q Q Q Q Less Cutting force 160412LE 1.2 2.0 D Q Q Q Q Q Q 3NC-TNGA 160402LT 0.2 2.4 Q D Q Q Q Q Q T00515 160404LT Q 1 3 0.4 2.3 Q D Q Q Q Q Q 160408LT 0.8 2.0 Q D Q Q Q Q Q SUMIBORON Sharper edge 160412LT 1.2 2.0 Q D Q Q Q Q Q *For use with SUMIBORON holders for high-efficiency machining shown on page L102. SUMIBORON Application Range Map Ⓐ Uncoated SUMIBORON Ⓑ Coated SUMIBORON (m/min) 300 (m/min) 300 BNC100 BN1000 BNC160 200 200 BNC2010 Speed BN2000 BNX25 Speed BNC2020 BNC200 BNX20 120 Cutting 100 BN350 Cutting 100 BNC300 0 Heavy 0 Heavy Continuous Interrupted Interrupted Continuous Interrupted Interrupted L66

Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo инструмент для отрезки

Каталог Sumitomo инструмент для отрезки Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal