Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron - страница 26

Навигация

- L001

- L002

- L003

- L004

- L005

- L006

- L007

- L008

- L009

- L010

- L011

- L012

- L013

- L014

- L015

- L016

- L017

- L018

- L019

- L020

- L021

- L022

- L023

- L024

- L025

- L026

- L027

- L028

- L029

- L030

- L031

- L032

- L033

- L034

- L035

- L036

- L037

- L038

- L039

- L040

- L041

- L042

- L043

- L044

- L045

- L046

- L047

- L048

- L049

- L050

- L051

- L052

- L053

- L054

- L055

- L056

- L057

- L058

- L059

- L060

- L061

- L062

- L063

- L064

- L065

- L066

- L067

- L068

- L069

- L070

- L071

- L072

- L073

- L074

- L075

- L076

- L077

- L078

- L079

- L080

- L081

- L082

- L083

- L084

- L085

- L086

- L087

- L088

- L089

- L090

- L091

- L092

- L093

- L094

- L095

- L096

- L097

- L098

- L099

- L100

- L101

- L102

- L103

- L104

- L105

- L106

- L107

- L108

- L109

- L110

- L111

- L112

- L113

- L114

- L115

- L116

- L117

- L118

- L119

- L120

- L121

- L122

- L123

- L124

- L125

- L126

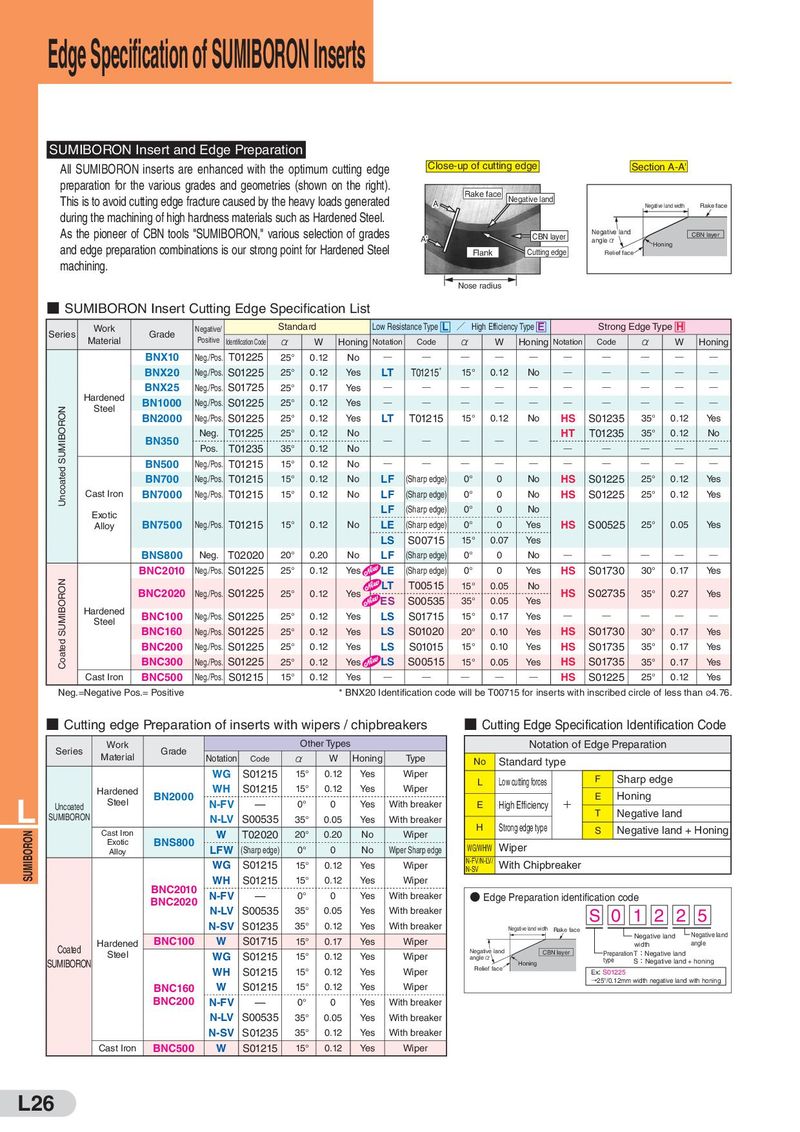

Edge Specification of SUMIBORON Inserts SUMIBORON Insert and Edge Preparation All SUMIBORON inserts are enhanced with the optimum cutting edge Close-up of cutting edge Section A-A' preparation for the various grades and geometries (shown on the right). Rake face This is to avoid cutting edge fracture caused by the heavy loads generated A Negative land Negative land width Rake face during the machining of high hardness materials such as Hardened Steel. As the pioneer of CBN tools "SUMIBORON," various selection of grades CBN layer Negative land CBN layer A' angle α Honing and edge preparation combinations is our strong point for Hardened Steel Flank Cutting edge Relief face machining. Nose radius ■ SUMIBORON Insert Cutting Edge Specification List Series Work Grade Negative/ Standard Low Resistance Type L / High Efficiency Type E Strong Edge Type H Material Positive Identification Code α W Honing Notation Code α W Honing Notation Code α W Honing BNX10 Neg./Pos. T01225 25° 0.12 No Q Q Q Q Q Q Q Q Q Q BNX20 Neg./Pos. S01225 25° 0.12 Yes LT T01215* 15° 0.12 No Q Q Q Q Q BNX25 Neg./Pos. S01725 25° 0.17 Yes Q Q Q Q Q Q Q Q Q Q Hardened BN1000 Neg./Pos. S01225 25° 0.12 Yes Q Q Q Q Q Q Q Q Q Q Uncoated SUMIBORON Steel BN2000 Neg./Pos. S01225 25° 0.12 Yes LT T01215 15° 0.12 No HS S01235 35° 0.12 Yes BN350 Neg. T01225 25° 0.12 No Q Q Q Q Q HT T01235 35° 0.12 No Pos. T01235 35° 0.12 No Q Q Q Q Q BN500 Neg./Pos. T01215 15° 0.12 No Q Q Q Q Q Q Q Q Q Q BN700 Neg./Pos. T01215 15° 0.12 No LF (Sharp edge) 0° 0 No HS S01225 25° 0.12 Yes Cast Iron BN7000 Neg./Pos. T01215 15° 0.12 No LF (Sharp edge) 0° 0 No HS S01225 25° 0.12 Yes Exotic LF (Sharp edge) 0° 0 No Alloy BN7500 Neg./Pos. T01215 15° 0.12 No LE (Sharp edge) 0° 0 Yes HS S00525 25° 0.05 Yes LS S00715 15° 0.07 Yes BNS800 Neg. T02020 20° 0.20 No LF (Sharp edge) 0° 0 No Q Q Q Q Q BNC2010 Neg./Pos. S01225 25° 0.12 Yes LE (Sharp edge) 0° 0 Yes HS S01730 30° 0.17 Yes Coated SUMIBORON BNC2020 Neg./Pos. S01225 25° 0.12 Yes LT T00515 15° 0.05 No HS S02735 35° 0.27 Yes ES S00535 35° 0.05 Yes Hardened BNC100 Neg./Pos. S01225 25° 0.12 Yes LS S01715 15° 0.17 Yes Q Q Q Q Q Steel BNC160 Neg./Pos. S01225 25° 0.12 Yes LS S01020 20° 0.10 Yes HS S01730 30° 0.17 Yes BNC200 Neg./Pos. S01225 25° 0.12 Yes LS S01015 15° 0.10 Yes HS S01735 35° 0.17 Yes BNC300 Neg./Pos. S01225 25° 0.12 Yes LS S00515 15° 0.05 Yes HS S01735 35° 0.17 Yes Cast Iron BNC500 Neg./Pos. S01215 15° 0.12 Yes Q Q Q Q Q HS S01225 25° 0.12 Yes Neg.=Negative Pos.= Positive * BNX20 Identification code will be T00715 for inserts with inscribed circle of less than Ø4.76. ■ Cutting edge Preparation of inserts with wipers / chipbreakers ■ Cutting Edge Specification Identification Code Series Work Grade Other Types Notation of Edge Preparation Material Notation Code α W Honing Type No Standard type WG S01215 15° 0.12 Yes Wiper L Low cutting forces F Sharp edge Hardened BN2000 WH S01215 15° 0.12 Yes Wiper E Honing L Uncoated Steel N-FV — 0° 0 Yes With breaker E High Efficiency + SUMIBORON N-LV S00535 35° 0.05 Yes With breaker T Negative land SUMIBORON Cast Iron W T02020 20° 0.20 No Wiper H Strong edge type S Negative land + Honing Exotic BNS800 LFW (Sharp edge) 0° 0 No Wiper Sharp edge WG/WH/W Wiper Alloy WG S01215 15° 0.12 Yes Wiper N-FV/N-LV/ With Chipbreaker N-SV WH S01215 15° 0.12 Yes Wiper BNC2010 N-FV — 0° 0 Yes With breaker ● Edge Preparation identification code BNC2020 N-LV S00535 35° 0.05 Yes With breaker N-SV S01235 35° 0.12 Yes With breaker S 0 1 2 2 5 Negative land width Rake face BNC100 W S01715 15° 0.17 Yes Wiper Negative land Negative land Coated Hardened width angle Steel WG S01215 15° 0.12 Yes Wiper Negative land CBN layer Preparation T:Negative land SUMIBORON angle α type S:Negative land + honing Relief face Honing WH S01215 15° 0.12 Yes Wiper Ex: S01225 W S01215 15° 0.12 Yes Wiper →25°/0.12mm width negative land with honing BNC160 BNC200 N-FV — 0° 0 Yes With breaker N-LV S00535 35° 0.05 Yes With breaker N-SV S01235 35° 0.12 Yes With breaker Cast Iron BNC500 W S01215 15° 0.12 Yes Wiper L26

Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo инструмент для отрезки

Каталог Sumitomo инструмент для отрезки Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal