Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron - страница 19

Навигация

- L001

- L002

- L003

- L004

- L005

- L006

- L007

- L008

- L009

- L010

- L011

- L012

- L013

- L014

- L015

- L016

- L017

- L018

- L019

- L020

- L021

- L022

- L023

- L024

- L025

- L026

- L027

- L028

- L029

- L030

- L031

- L032

- L033

- L034

- L035

- L036

- L037

- L038

- L039

- L040

- L041

- L042

- L043

- L044

- L045

- L046

- L047

- L048

- L049

- L050

- L051

- L052

- L053

- L054

- L055

- L056

- L057

- L058

- L059

- L060

- L061

- L062

- L063

- L064

- L065

- L066

- L067

- L068

- L069

- L070

- L071

- L072

- L073

- L074

- L075

- L076

- L077

- L078

- L079

- L080

- L081

- L082

- L083

- L084

- L085

- L086

- L087

- L088

- L089

- L090

- L091

- L092

- L093

- L094

- L095

- L096

- L097

- L098

- L099

- L100

- L101

- L102

- L103

- L104

- L105

- L106

- L107

- L108

- L109

- L110

- L111

- L112

- L113

- L114

- L115

- L116

- L117

- L118

- L119

- L120

- L121

- L122

- L123

- L124

- L125

- L126

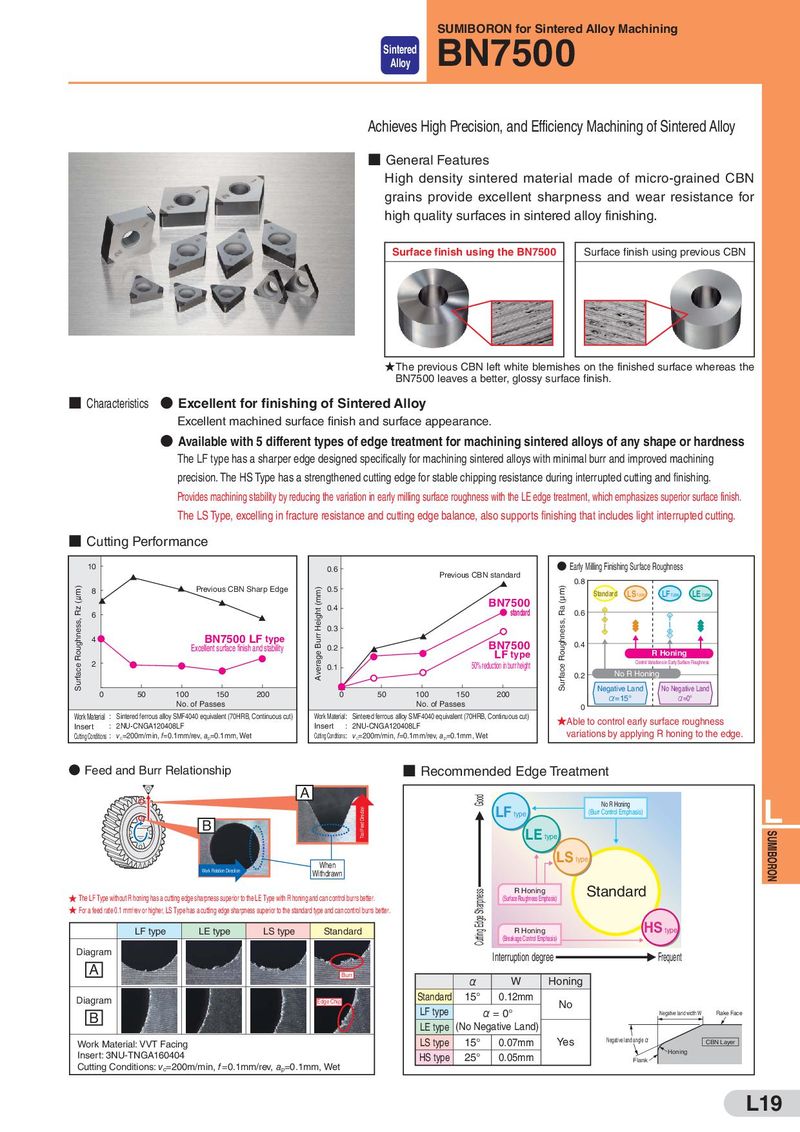

SUMIBORON for Sintered Alloy Machining Sintered BN7500 Alloy Achieves High Precision, and Efficiency Machining of Sintered Alloy ■ General Features High density sintered material made of micro-grained CBN grains provide excellent sharpness and wear resistance for high quality surfaces in sintered alloy finishing. Surface finish using the BN7500 Surface finish using previous CBN ★The previous CBN left white blemishes on the finished surface whereas the BN7500 leaves a better, glossy surface finish. ■ Characteristics ● Excellent for finishing of Sintered Alloy Excellent machined surface finish and surface appearance. ● Available with 5 different types of edge treatment for machining sintered alloys of any shape or hardness The LF type has a sharper edge designed specifically for machining sintered alloys with minimal burr and improved machining precision. The HS Type has a strengthened cutting edge for stable chipping resistance during interrupted cutting and finishing. Provides machining stability by reducing the variation in early milling surface roughness with the LE edge treatment, which emphasizes superior surface finish. The LS Type, excelling in fracture resistance and cutting edge balance, also supports finishing that includes light interrupted cutting. ■ Cutting Performance 10 0.6 ● Early Milling Finishing Surface Roughness Previous CBN standard 0.8 Surface Roughness, Rz (μm) 8 Previous CBN Sharp Edge Average Burr Height (mm) 0.5 Surface Roughness, Ra (μm) Standard LS type LF type LE type 0.4 BN7500 standard 6 0.6 0.3 4 BN7500 LF type BN7500 0.4 Excellent surface finish and stability 0.2 LF type R Honing 2 0.1 50% reduction in burr height Control Variations in Early Surface Roughness 0.2 No R Honing 0 50 100 150 200 0 50 100 150 200 Negative Land No Negative Land No. of Passes No. of Passes α=15° α=0° 0 Work Material : Sintered ferrous alloy SMF4040 equivalent (70HRB, Continuous cut) Work Material: Sintered ferrous alloy SMF4040 equivalent (70HRB, Continuous cut) ★Able to control early surface roughness Insert : 2NU-CNGA120408LF Insert : 2NU-CNGA120408LF variations by applying R honing to the edge. Cutting Conditions : vc=200m/min, f=0.1mm/rev, ap=0.1mm, Wet Cutting Conditions: vc=200m/min, f=0.1mm/rev, ap=0.1mm, Wet ● Feed and Burr Relationship ■ Recommended Edge Treatment A Good L Tool Feed Direction LF type No R Honing (Burr Control Emphasis) B LE type SUMIBORON When LS type Work Rotation Direction Withdrawn Cutting Edge Sharpness R Honing Standard ★ The LF Type without R honing has a cutting edge sharpness superior to the LE Type with R honing and can control burrs better. (Surface Roughness Emphasis) ★ For a feed rate 0.1 mm/rev or higher, LS Type has a cutting edge sharpness superior to the standard type and can control burrs better. LF type LE type LS type Standard R Honing HS type (Breakage Control Emphasis) Diagram Interruption degree Frequent A Burr W Honing α Diagram Edge Chip Standard 15° 0.12mm No B LF type α = 0° Negative land width W Rake Face LE type (No Negative Land) Work Material: VVT Facing LS type 15° 0.07mm Yes Negative land angle α CBN Layer Insert: 3NU-TNGA160404 HS type 25° 0.05mm Honing Cutting Conditions: vc=200m/min, f =0.1mm/rev, ap=0.1mm, Wet Flank L19

Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo инструмент для отрезки

Каталог Sumitomo инструмент для отрезки Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal