Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron - страница 18

Навигация

- L001

- L002

- L003

- L004

- L005

- L006

- L007

- L008

- L009

- L010

- L011

- L012

- L013

- L014

- L015

- L016

- L017

- L018

- L019

- L020

- L021

- L022

- L023

- L024

- L025

- L026

- L027

- L028

- L029

- L030

- L031

- L032

- L033

- L034

- L035

- L036

- L037

- L038

- L039

- L040

- L041

- L042

- L043

- L044

- L045

- L046

- L047

- L048

- L049

- L050

- L051

- L052

- L053

- L054

- L055

- L056

- L057

- L058

- L059

- L060

- L061

- L062

- L063

- L064

- L065

- L066

- L067

- L068

- L069

- L070

- L071

- L072

- L073

- L074

- L075

- L076

- L077

- L078

- L079

- L080

- L081

- L082

- L083

- L084

- L085

- L086

- L087

- L088

- L089

- L090

- L091

- L092

- L093

- L094

- L095

- L096

- L097

- L098

- L099

- L100

- L101

- L102

- L103

- L104

- L105

- L106

- L107

- L108

- L109

- L110

- L111

- L112

- L113

- L114

- L115

- L116

- L117

- L118

- L119

- L120

- L121

- L122

- L123

- L124

- L125

- L126

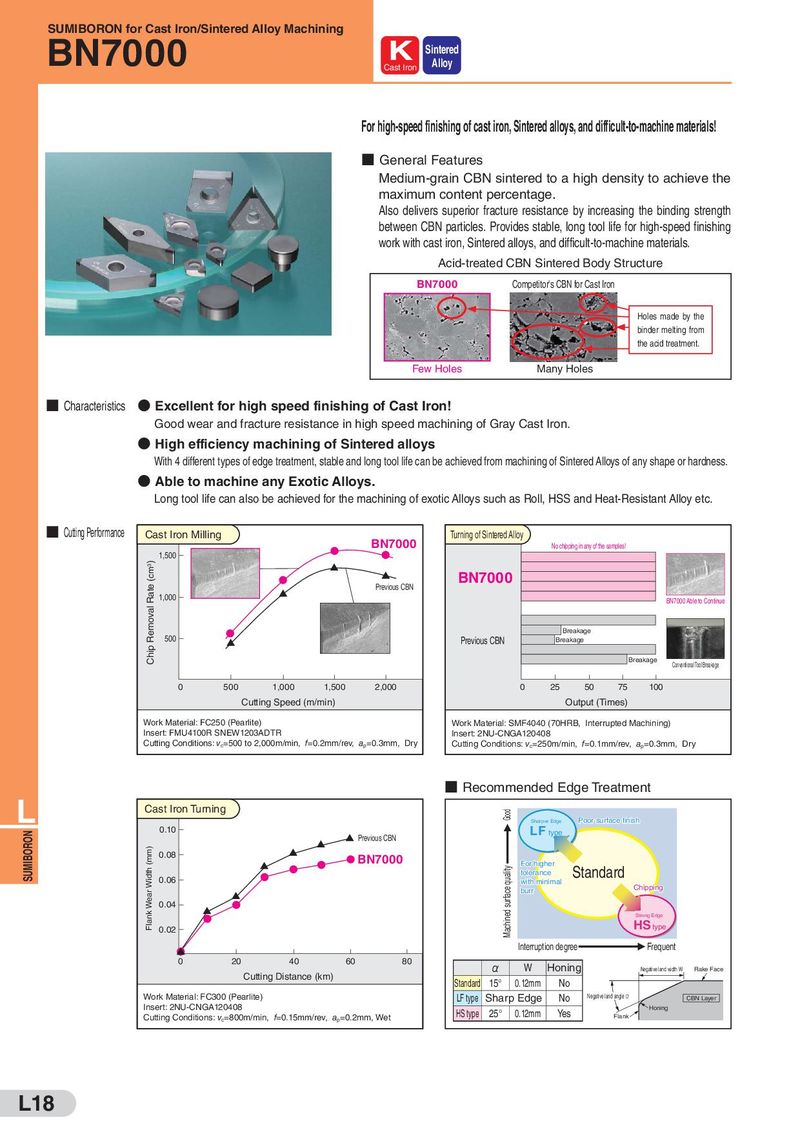

SUMIBORON for Cast Iron/Sintered Alloy Machining BN7000 K Sintered Cast Iron Alloy For high-speed finishing of cast iron, Sintered alloys, and difficult-to-machine materials! ■ General Features Medium-grain CBN sintered to a high density to achieve the maximum content percentage. Also delivers superior fracture resistance by increasing the binding strength between CBN particles. Provides stable, long tool life for high-speed finishing work with cast iron, Sintered alloys, and difficult-to-machine materials. Acid-treated CBN Sintered Body Structure BN7000 Competitor's CBN for Cast Iron Holes made by the binder melting from the acid treatment. Few Holes Many Holes ■ Characteristics ● Excellent for high speed finishing of Cast Iron! Good wear and fracture resistance in high speed machining of Gray Cast Iron. ● High efficiency machining of Sintered alloys With 4 different types of edge treatment, stable and long tool life can be achieved from machining of Sintered Alloys of any shape or hardness. ● Able to machine any Exotic Alloys. Long tool life can also be achieved for the machining of exotic Alloys such as Roll, HSS and Heat-Resistant Alloy etc. ■ Cutting Performance Cast Iron Milling BN7000 Turning of Sintered Alloy No chipping in any of the samples! 1,500 Chip Removal Rate (cm3) Previous CBN BN7000 1,000 BN7000 Able to Continue Breakage 500 Previous CBN Breakage Breakage Conventional Tool Breakage 0 500 1,000 1,500 2,000 0 25 50 75 100 Cutting Speed (m/min) Output (Times) Work Material: FC250 (Pearlite) Work Material: SMF4040 (70HRB, Interrupted Machining) Insert: FMU4100R SNEW1203ADTR Insert: 2NU-CNGA120408 Cutting Conditions: vc=500 to 2,000m/min, f=0.2mm/rev, ap=0.3mm, Dry Cutting Conditions: vc=250m/min, f=0.1mm/rev, ap=0.3mm, Dry ■ Recommended Edge Treatment L Cast Iron Turning Good Sharper Edge Poor surface finish SUMIBORON 0.10 Previous CBN L F type Flank Wear Width (mm) 0.08 BN7000 Machined surface quality For higher Standard 0.06 tolerance with minimal Chipping burr 0.04 Strong Edge 0.02 HS type Interruption degree Frequent 0 20 40 60 80 α W Honing Negative land width W Rake Face Cutting Distance (km) Standard 15° 0.12mm No Work Material: FC300 (Pearlite) LF type Sharp Edge No Negative land angle α CBN Layer Insert: 2NU-CNGA120408 HS type 25° 0.12mm Yes Honing Cutting Conditions: vc=800m/min, f=0.15mm/rev, ap=0.2mm, Wet Flank L18

Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo инструмент для отрезки

Каталог Sumitomo инструмент для отрезки Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal