Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron - страница 20

Навигация

- L001

- L002

- L003

- L004

- L005

- L006

- L007

- L008

- L009

- L010

- L011

- L012

- L013

- L014

- L015

- L016

- L017

- L018

- L019

- L020

- L021

- L022

- L023

- L024

- L025

- L026

- L027

- L028

- L029

- L030

- L031

- L032

- L033

- L034

- L035

- L036

- L037

- L038

- L039

- L040

- L041

- L042

- L043

- L044

- L045

- L046

- L047

- L048

- L049

- L050

- L051

- L052

- L053

- L054

- L055

- L056

- L057

- L058

- L059

- L060

- L061

- L062

- L063

- L064

- L065

- L066

- L067

- L068

- L069

- L070

- L071

- L072

- L073

- L074

- L075

- L076

- L077

- L078

- L079

- L080

- L081

- L082

- L083

- L084

- L085

- L086

- L087

- L088

- L089

- L090

- L091

- L092

- L093

- L094

- L095

- L096

- L097

- L098

- L099

- L100

- L101

- L102

- L103

- L104

- L105

- L106

- L107

- L108

- L109

- L110

- L111

- L112

- L113

- L114

- L115

- L116

- L117

- L118

- L119

- L120

- L121

- L122

- L123

- L124

- L125

- L126

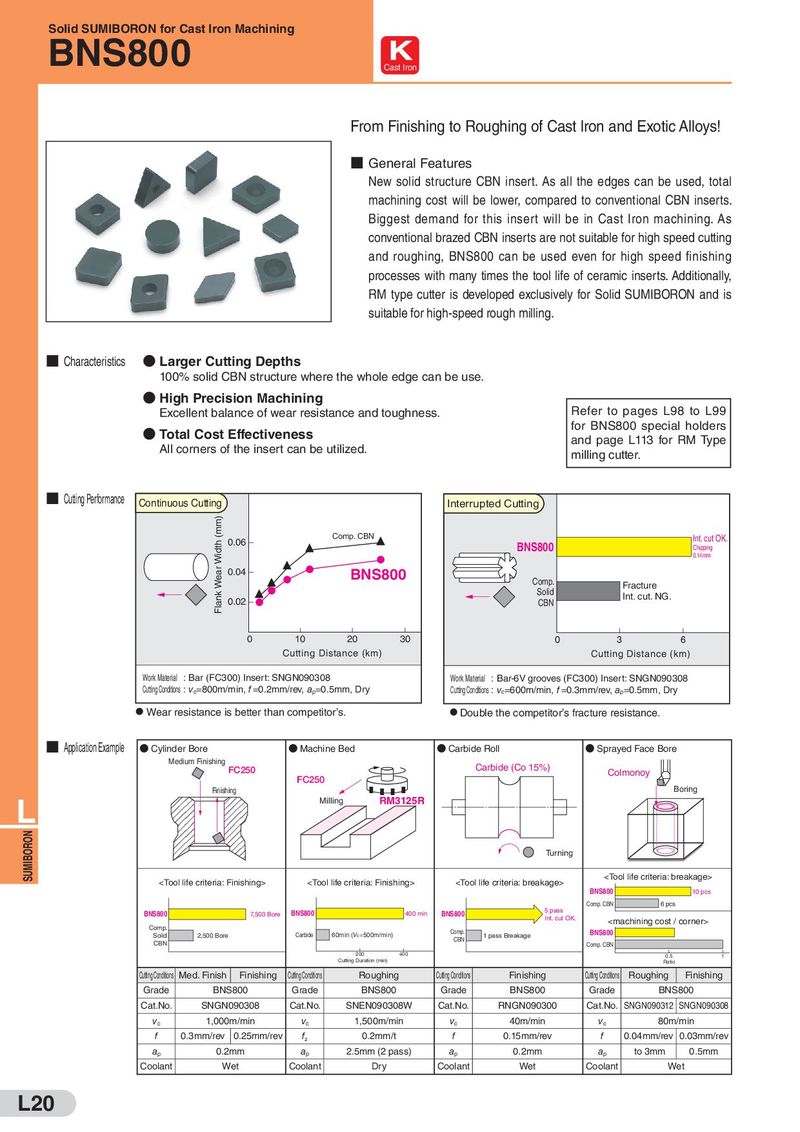

Solid SUMIBORON for Cast Iron Machining

B NS800 K

Cast Iron

From Finishing to Roughing of Cast lron and Exotic Alloys!

■ General Features

New solid structure CBN insert. As all the edges can be used, total

machining cost will be lower, compared to conventional CBN inserts.

Biggest demand for this insert will be in Cast Iron machining. As

conventional brazed CBN inserts are not suitable for high speed cutting

and roughing, BNS800 can be used even for high speed finishing

processes with many times the tool life of ceramic inserts. Additionally,

RM type cutter is developed exclusively for Solid SUMIBORON and is

suitable for high-speed rough milling.

■ Characteristics ● Larger Cutting Depths

100% solid CBN structure where the whole edge can be use.

● High Precision Machining

Excellent balance of wear resistance and toughness. Refer to pages L98 to L99

● Total Cost Effectiveness for BNS800 special holders

All corners of the insert can be utilized. and page L113 for RM Type

milling cutter.

■ Cutting Performance Continuous Cutting Interrupted Cutting

Flank Wear Width (mm) 0.06 Comp. CBN F BNS800 Int. cut OK.

F Chipping

D 0.14mm

0.04 F D BNS800

F D Comp. Fracture

FD Solid Int. cut. NG.

0.02 D CBN

0 10 20 30 0 3 6

Cutting Distance (km) Cutting Distance (km)

Work Material : Bar (FC300) Insert: SNGN090308 Work Material : Bar-6V grooves (FC300) Insert: SNGN090308

Cutting Conditions : vc=800m/min, f =0.2mm/rev, ap=0.5mm, Dry Cutting Conditions : vc=600m/min, f =0.3mm/rev, ap=0.5mm, Dry

● Wear resistance is better than competitor’s. ● Double the competitor’s fracture resistance.

■ Application Example ● Cylinder Bore ● Machine Bed ● Carbide Roll ● Sprayed Face Bore

Medium Finishing Carbide (Co 15%)

FC250 Colmonoy

FC250

Finishing Boring

L Milling RM3125R

SUMIBORON Turning

Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo инструмент для отрезки

Каталог Sumitomo инструмент для отрезки Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal