Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron - страница 115

Навигация

- L001

- L002

- L003

- L004

- L005

- L006

- L007

- L008

- L009

- L010

- L011

- L012

- L013

- L014

- L015

- L016

- L017

- L018

- L019

- L020

- L021

- L022

- L023

- L024

- L025

- L026

- L027

- L028

- L029

- L030

- L031

- L032

- L033

- L034

- L035

- L036

- L037

- L038

- L039

- L040

- L041

- L042

- L043

- L044

- L045

- L046

- L047

- L048

- L049

- L050

- L051

- L052

- L053

- L054

- L055

- L056

- L057

- L058

- L059

- L060

- L061

- L062

- L063

- L064

- L065

- L066

- L067

- L068

- L069

- L070

- L071

- L072

- L073

- L074

- L075

- L076

- L077

- L078

- L079

- L080

- L081

- L082

- L083

- L084

- L085

- L086

- L087

- L088

- L089

- L090

- L091

- L092

- L093

- L094

- L095

- L096

- L097

- L098

- L099

- L100

- L101

- L102

- L103

- L104

- L105

- L106

- L107

- L108

- L109

- L110

- L111

- L112

- L113

- L114

- L115

- L116

- L117

- L118

- L119

- L120

- L121

- L122

- L123

- L124

- L125

- L126

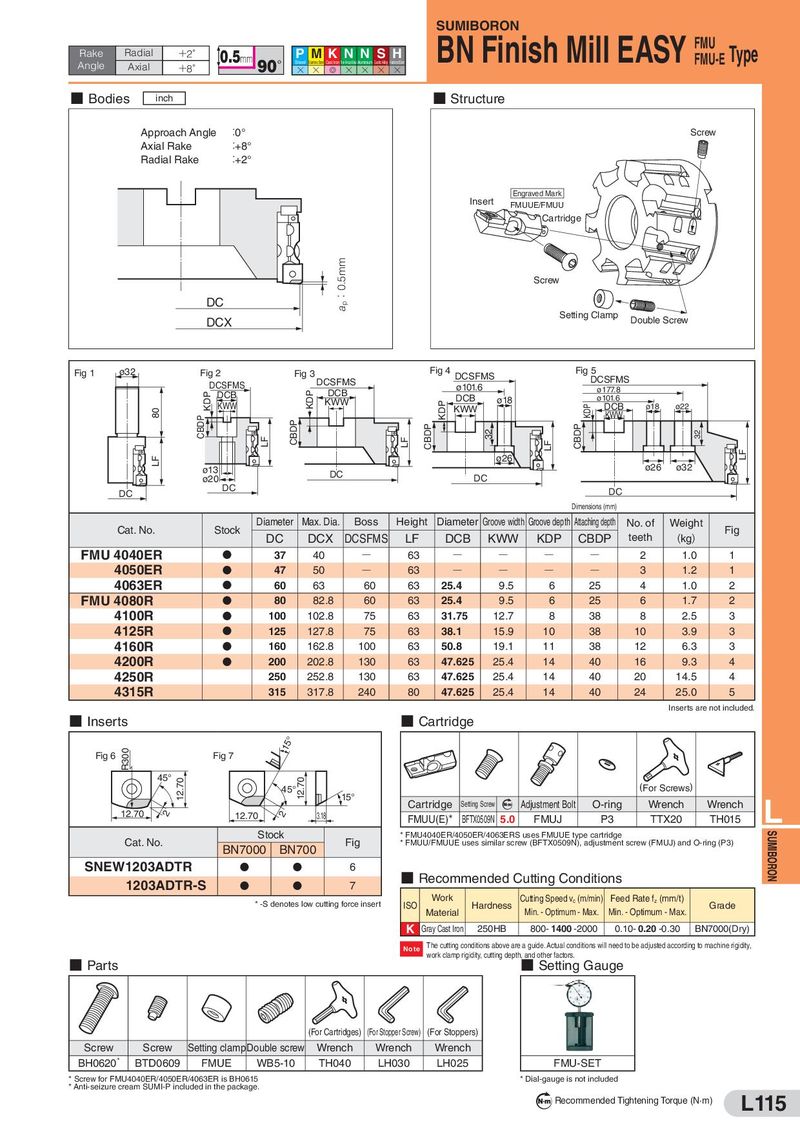

SUMIBORON Rake Radial +2° 0.5mm P MK N N S H BN Finish Mill EASY FMU Type FMU-E Angle Axial +8° 90° Steel Stainless Steel Cast Iron Non-FerrousMetal Aluminium Exotic Alloy HardenedSteel H H G H H H H ■ Bodies inch ■ Structure Approach Angle :0° Screw Axial Rake :+8° Radial Rake :+2° Engraved Mark Insert FMUUE/FMUU Cartridge ap:0.5mm Screw DC DCX Setting Clamp Double Screw Fig 1 ø32 Fig 2 Fig 3 Fig 4 DCSFMS Fig 5 DCSFMS DCSFMS ø101.6 DCSFMS CBDP KDP DCB KDP DCB ø177.8 KWW KWW KDP DCB ø18 ø101.6 80 KWW KDP DCB ø18 ø22 CBDP KWW LF LF CBDP 32 CBDP 32 LF LF LF ø26 ø13 DC ø26 ø32 ø20 DC DC DC DC Dimensions (mm) Cat. No. Stock Diameter Max. Dia. Boss Height Diameter Groove width Groove depth Attaching depth No. of Weight Fig DC DCX DCSFMS LF DCB KWW KDP CBDP teeth (kg) FMU 4040ER D 37 40 Q 63 Q Q Q Q 2 1.0 1 4050ER D 47 50 Q 63 Q Q Q Q 3 1.2 1 4063ER D 60 63 60 63 25.4 9.5 6 25 4 1.0 2 FMU 4080R D 80 82.8 60 63 25.4 9.5 6 25 6 1.7 2 4100R D 100 102.8 75 63 31.75 12.7 8 38 8 2.5 3 4125R D 125 127.8 75 63 38.1 15.9 10 38 10 3.9 3 4160R D 160 162.8 100 63 50.8 19.1 11 38 12 6.3 3 4200R D 200 202.8 130 63 47.625 25.4 14 40 16 9.3 4 4250R 250 252.8 130 63 47.625 25.4 14 40 20 14.5 4 4315R 315 317.8 240 80 47.625 25.4 14 40 24 25.0 5 Inserts are not included. ■ Inserts ■ Cartridge R300 15° Fig 6 Fig 7 45° 12.70 12.70 45° (For Screws) 15° Cartridge Setting Screw Adjustment Bolt O-ring Wrench Wrench L 12.70 2 12.70 2 3.18 FMUU(E)* BFTX0509N 5.0 FMUJ P3 TTX20 TH015 Cat. No. Stock Fig * FMU4040ER/4050ER/4063ERS uses FMUUE type cartridge SUMIBORON BN7000 BN700 * FMUU/FMUUE uses similar screw (BFTX0509N), adjustment screw (FMUJ) and O-ring (P3) SNEW1203ADTR D D 6 ■ Recommended Cutting Conditions 1203ADTR-S D D 7 * -S denotes low cutting force insert ISO Work Hardness Cutting Speed vc (m/min) Feed Rate fz (mm/t) Grade Material Min. - Optimum - Max. Min. - Optimum - Max. K Gray Cast Iron 250HB 800- 1400 -2000 0.10- 0.20 -0.30 BN7000(Dry) Note The cutting conditions above are a guide. Actual conditions will need to be adjusted according to machine rigidity, work clamp rigidity, cutting depth, and other factors. ■ Parts ■ Setting Gauge (For Cartridges) (For Stopper Screw) (For Stoppers) Screw Screw Setting clampDouble screw Wrench Wrench Wrench BH0620* BTD0609 FMUE WB5-10 TH040 LH030 LH025 FMU-SET * Screw for FMU4040ER/4050ER/4063ER is BH0615 * Dial-gauge is not included * Anti-seizure cream SUMI-P included in the package. Recommended Tightening Torque (N·m) L115

Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo инструмент для отрезки

Каталог Sumitomo инструмент для отрезки Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal