Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron - страница 103

Навигация

- L001

- L002

- L003

- L004

- L005

- L006

- L007

- L008

- L009

- L010

- L011

- L012

- L013

- L014

- L015

- L016

- L017

- L018

- L019

- L020

- L021

- L022

- L023

- L024

- L025

- L026

- L027

- L028

- L029

- L030

- L031

- L032

- L033

- L034

- L035

- L036

- L037

- L038

- L039

- L040

- L041

- L042

- L043

- L044

- L045

- L046

- L047

- L048

- L049

- L050

- L051

- L052

- L053

- L054

- L055

- L056

- L057

- L058

- L059

- L060

- L061

- L062

- L063

- L064

- L065

- L066

- L067

- L068

- L069

- L070

- L071

- L072

- L073

- L074

- L075

- L076

- L077

- L078

- L079

- L080

- L081

- L082

- L083

- L084

- L085

- L086

- L087

- L088

- L089

- L090

- L091

- L092

- L093

- L094

- L095

- L096

- L097

- L098

- L099

- L100

- L101

- L102

- L103

- L104

- L105

- L106

- L107

- L108

- L109

- L110

- L111

- L112

- L113

- L114

- L115

- L116

- L117

- L118

- L119

- L120

- L121

- L122

- L123

- L124

- L125

- L126

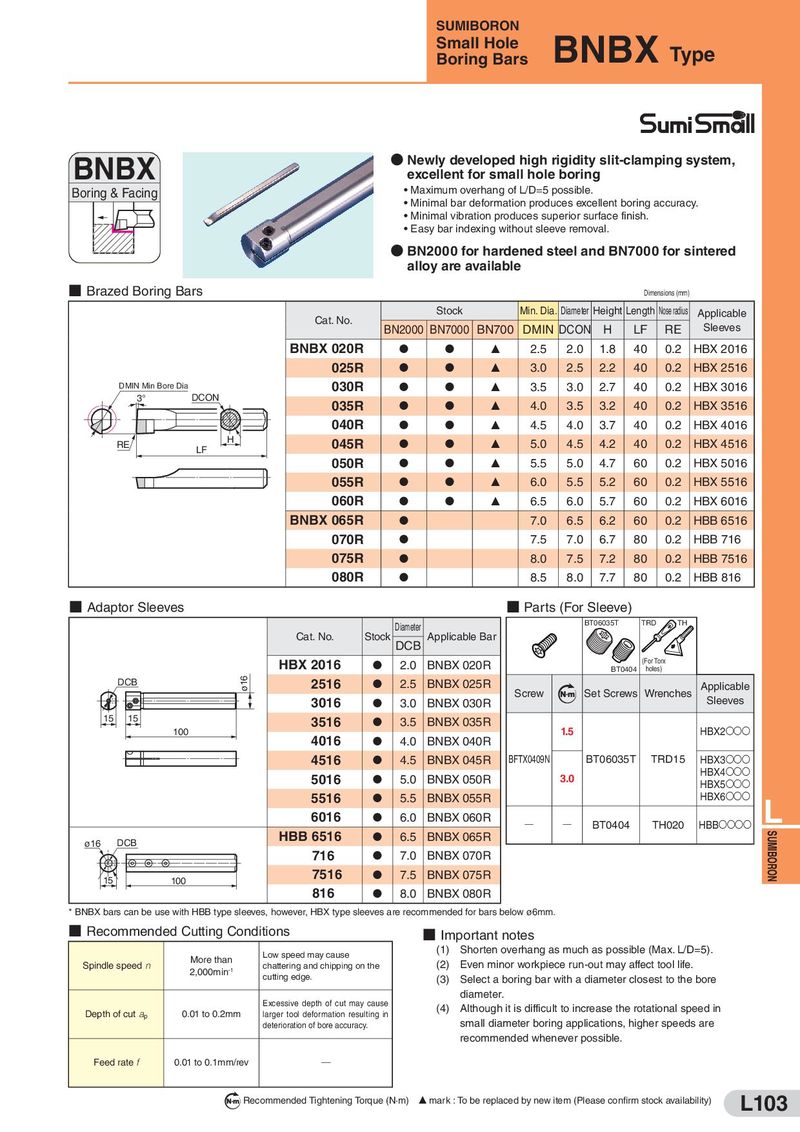

SUMIBORON BNBX Type Small Hole Boring Bars BNBX ● Newly developed high rigidity slit-clamping system, excellent for small hole boring Boring & Facing • Maximum overhang of L/D=5 possible. • Minimal bar deformation produces excellent boring accuracy. • Minimal vibration produces superior surface finish. • Easy bar indexing without sleeve removal. ● BN2000 for hardened steel and BN7000 for sintered alloy are available ■ Brazed Boring Bars Dimensions (mm) Cat. No. Stock Min. Dia. Diameter Height Length Nose radius Applicable BN2000 BN7000 BN700 DMIN DCON H LF RE Sleeves BNBX 020R D D F 2.5 2.0 1.8 40 0.2 HBX 2016 025R D D F 3.0 2.5 2.2 40 0.2 HBX 2516 DMIN Min Bore Dia 030R D D F 3.5 3.0 2.7 40 0.2 HBX 3016 3° DCON 035R D D F 4.0 3.5 3.2 40 0.2 HBX 3516 040R D D F 4.5 4.0 3.7 40 0.2 HBX 4016 RE H 045R D D F 5.0 4.5 4.2 40 0.2 HBX 4516 LF 050R D D F 5.5 5.0 4.7 60 0.2 HBX 5016 055R D D F 6.0 5.5 5.2 60 0.2 HBX 5516 060R D D F 6.5 6.0 5.7 60 0.2 HBX 6016 BNBX 065R D 7.0 6.5 6.2 60 0.2 HBB 6516 070R D 7.5 7.0 6.7 80 0.2 HBB 716 075R D 8.0 7.5 7.2 80 0.2 HBB 7516 080R D 8.5 8.0 7.7 80 0.2 HBB 816 ■ Adaptor Sleeves ■ Parts (For Sleeve) Diameter BT06035T TRD TH Cat. No. Stock DCB Applicable Bar HBX 2016 D 2.0 BNBX 020R (For Torx BT0404 holes) DCB ø16 2516 D 2.5 BNBX 025R Applicable 3016 3.0 BNBX 030R Screw Set Screws Wrenches Sleeves D 15 15 3516 D 3.5 BNBX 035R 100 4016 4.0 BNBX 040R 1.5 HBX2SSS D 4516 D 4.5 BNBX 045R BFTX0409N BT06035T TRD15 HBX3SSS 5016 D 5.0 BNBX 050R 3.0 HBX4SSS HBX5SSS 5516 D 5.5 BNBX 055R HBX6SSS L 6016 D 6.0 BNBX 060R Q Q BT0404 TH020 HBBSSSS ø16 DCB HBB 6516 D 6.5 BNBX 065R SUMIBORON 716 D 7.0 BNBX 070R 15 100 7516 D 7.5 BNBX 075R 816 D 8.0 BNBX 080R * BNBX bars can be use with HBB type sleeves, however, HBX type sleeves are recommended for bars below ø6mm. ■ Recommended Cutting Conditions ■ Important notes Low speed may cause (1) Shorten overhang as much as possible (Max. L/D=5). Spindle speed n More than chattering and chipping on the (2) Even minor workpiece run-out may affect tool life. 2,000min-1 cutting edge. (3) Select a boring bar with a diameter closest to the bore diameter. Excessive depth of cut may cause (4) Although it is difficult to increase the rotational speed in Depth of cut ap 0.01 to 0.2mm larger tool deformation resulting in deterioration of bore accuracy. small diameter boring applications, higher speeds are recommended whenever possible. Feed rate f 0.01 to 0.1mm/rev ― Recommended Tightening Torque (N·m) F mark : To be replaced by new item (Please confirm stock availability) L103

Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo инструмент для отрезки

Каталог Sumitomo инструмент для отрезки Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal