Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron - страница 113

Навигация

- L001

- L002

- L003

- L004

- L005

- L006

- L007

- L008

- L009

- L010

- L011

- L012

- L013

- L014

- L015

- L016

- L017

- L018

- L019

- L020

- L021

- L022

- L023

- L024

- L025

- L026

- L027

- L028

- L029

- L030

- L031

- L032

- L033

- L034

- L035

- L036

- L037

- L038

- L039

- L040

- L041

- L042

- L043

- L044

- L045

- L046

- L047

- L048

- L049

- L050

- L051

- L052

- L053

- L054

- L055

- L056

- L057

- L058

- L059

- L060

- L061

- L062

- L063

- L064

- L065

- L066

- L067

- L068

- L069

- L070

- L071

- L072

- L073

- L074

- L075

- L076

- L077

- L078

- L079

- L080

- L081

- L082

- L083

- L084

- L085

- L086

- L087

- L088

- L089

- L090

- L091

- L092

- L093

- L094

- L095

- L096

- L097

- L098

- L099

- L100

- L101

- L102

- L103

- L104

- L105

- L106

- L107

- L108

- L109

- L110

- L111

- L112

- L113

- L114

- L115

- L116

- L117

- L118

- L119

- L120

- L121

- L122

- L123

- L124

- L125

- L126

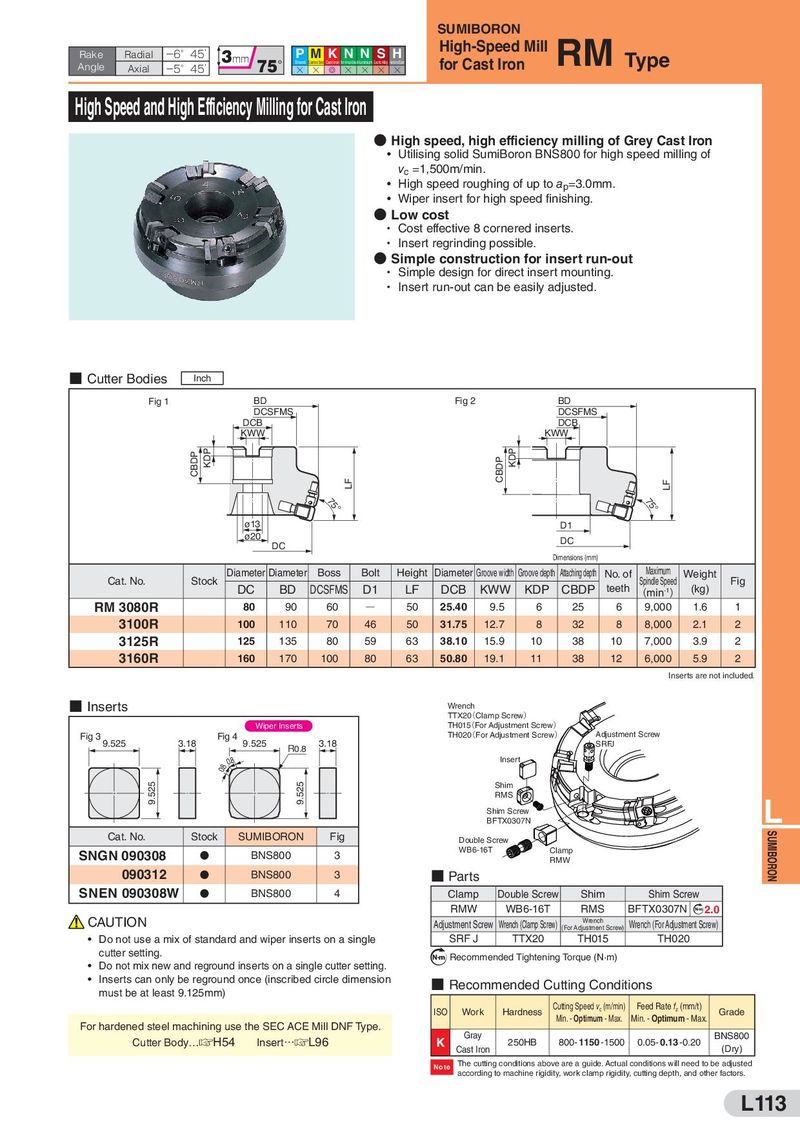

SUMIBORON Rake Radial −6°45 3mm P MKNN SH High-Speed Mill RM Type 75° for Cast lron Angle Steel Stainless Steel Cast Iron Non-FerrousMetal Aluminium Exotic Alloy HardenedSteel Axial −5°45 H H G H H H H High Speed and High Efficiency Milling for Cast Iron ● High speed, high efficiency milling of Grey Cast Iron • Utilising solid SumiBoron BNS800 for high speed milling of vc =1,500m/min. • High speed roughing of up to ap=3.0mm. • Wiper insert for high speed finishing. ● Low cost • Cost effective 8 cornered inserts. • Insert regrinding possible. ● Simple construction for insert run-out • Simple design for direct insert mounting. • Insert run-out can be easily adjusted. ■ Cutter Bodies Inch Fig 1 BD Fig 2 BD DCSFMS DCSFMS DCB DCB KWW KWW CBDP KDP CBDP KDP LF LF 75° 75° ø13 D1 ø20 DC DC Dimensions (mm) Diameter Diameter Boss Bolt Height Diameter Groove width Groove depth Attaching depth No. of Maximum Weight Cat. No. Stock DC BD DCSFMS D1 LF DCB KWW KDP CBDP teeth Spindle Speed (kg) Fig (min-1) RM 3080R 80 90 60 Q 50 25.40 9.5 6 25 6 9,000 1.6 1 3100R 100 110 70 46 50 31.75 12.7 8 32 8 8,000 2.1 2 3125R 125 135 80 59 63 38.10 15.9 10 38 10 7,000 3.9 2 3160R 160 170 100 80 63 50.80 19.1 11 38 12 6,000 5.9 2 Inserts are not included. ■ Inserts Wrench TTX20(Clamp Screw) Wiper Inserts TH015(For Adjustment Screw) Fig 3 Fig 4 TH020(For Adjustment Screw) Adjustment Screw 9.525 3.18 9.525 R0.8 3.18 SRFJ 0.8 Insert 0.8 9.525 9.525 Shim RMS L Shim Screw BFTX0307N Cat. No. Stock SUMIBORON Fig Double Screw SUMIBORON SNGN 090308 D BNS800 3 WB6-16T Clamp RMW 090312 D BNS800 3 ■ Parts SNEN 090308W D BNS800 4 Clamp Double Screw Shim Shim Screw RMW WB6-16T RMS BFTX0307N N m 2.0 CAUTION Adjustment Screw Wrench (Clamp Screw) Wrench Wrench (For Adjustment Screw) (For Adjustment Screw) • Do not use a mix of standard and wiper inserts on a single SRF J TTX20 TH015 TH020 cutter setting. N m Recommended Tightening Torque (N·m) • Do not mix new and reground inserts on a single cutter setting. • Inserts can only be reground once (inscribed circle dimension ■ Recommended Cutting Conditions must be at least 9.125mm) ISO Work Hardness Cutting Speed vc (m/min) Feed Rate fz (mm/t) Grade For hardened steel machining use the SEC ACE Mill DNF Type. Min. - Optimum - Max. Min. - Optimum - Max. Cutter Body… H54 Insert… L96 K Gray 250HB 800- 1150 -1500 0.05- 0.13 -0.20 BNS800 Cast Iron (Dry) Note The cutting conditions above are a guide. Actual conditions will need to be adjusted according to machine rigidity, work clamp rigidity, cutting depth, and other factors. L113

Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo инструмент для отрезки

Каталог Sumitomo инструмент для отрезки Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal