Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron - страница 10

Навигация

- L001

- L002

- L003

- L004

- L005

- L006

- L007

- L008

- L009

- L010

- L011

- L012

- L013

- L014

- L015

- L016

- L017

- L018

- L019

- L020

- L021

- L022

- L023

- L024

- L025

- L026

- L027

- L028

- L029

- L030

- L031

- L032

- L033

- L034

- L035

- L036

- L037

- L038

- L039

- L040

- L041

- L042

- L043

- L044

- L045

- L046

- L047

- L048

- L049

- L050

- L051

- L052

- L053

- L054

- L055

- L056

- L057

- L058

- L059

- L060

- L061

- L062

- L063

- L064

- L065

- L066

- L067

- L068

- L069

- L070

- L071

- L072

- L073

- L074

- L075

- L076

- L077

- L078

- L079

- L080

- L081

- L082

- L083

- L084

- L085

- L086

- L087

- L088

- L089

- L090

- L091

- L092

- L093

- L094

- L095

- L096

- L097

- L098

- L099

- L100

- L101

- L102

- L103

- L104

- L105

- L106

- L107

- L108

- L109

- L110

- L111

- L112

- L113

- L114

- L115

- L116

- L117

- L118

- L119

- L120

- L121

- L122

- L123

- L124

- L125

- L126

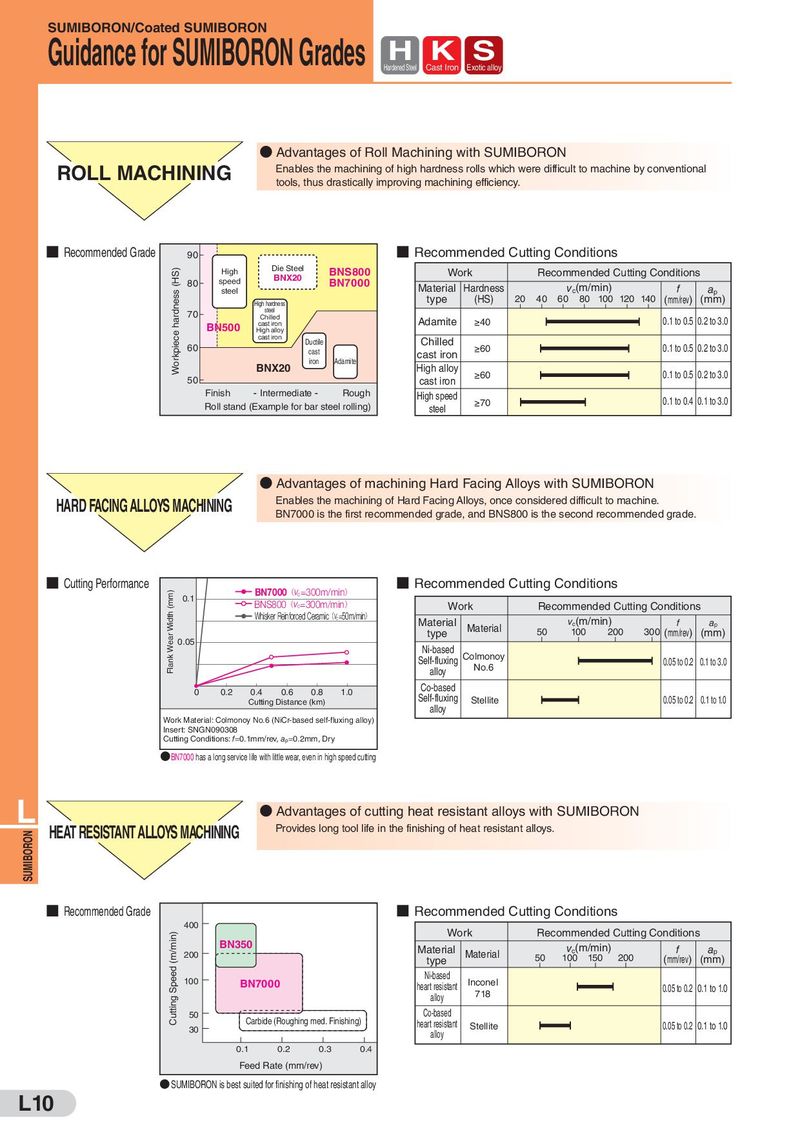

SUMIBORON/Coated SUMIBORON Guidance for SUMIBORON Grades H K S Hardened Steel Cast Iron Exotic alloy ● Advantages of Roll Machining with SUMIBORON ROLL MACHINING Enables the machining of high hardness rolls which were difficult to machine by conventional tools, thus drastically improving machining efficiency. ■ Recommended Grade 90 ■ Recommended Cutting Conditions Workpiece hardness (HS) High Die Steel BNS800 Work Recommended Cutting Conditions 80 speed BNX20 BN7000 steel Material Hardness vc(m/min) f ap High hardness type (HS) 20 40 60 80 100 120 140 (mm/rev) (mm) 70 steel Chilled Adamite ≥40 0.1 to 0.5 0.2 to 3.0 BN500 cast iron High alloy cast iron Ductile Chilled 60 cast cast iron ≥60 0.1 to 0.5 0.2 to 3.0 BNX20 iron Adamite High alloy 50 cast iron ≥60 0.1 to 0.5 0.2 to 3.0 Finish - Intermediate - Rough High speed 0.1 to 0.4 0.1 to 3.0 Roll stand (Example for bar steel rolling) steel ≥70 ● Advantages of machining Hard Facing Alloys with SUMIBORON HARD FACING ALLOYS MACHINING Enables the machining of Hard Facing Alloys, once considered difficult to machine. BN7000 is the first recommended grade, and BNS800 is the second recommended grade. ■ Cutting Performance Flank Wear Width (mm) BN7000(vc=300m/min) ■ Recommended Cutting Conditions 0.1 BNS800(vc=300m/min) Work Recommended Cutting Conditions Whisker Reinforced Ceramic(vc=50m/min) Material vc(m/min) f ap type Material 50 100 200 300 (mm/rev) (mm) 0.05 Ni-based Self-fluxing Colmonoy 0.05 to 0.2 0.1 to 3.0 alloy No.6 0 0.2 0.4 0.6 0.8 1.0 Co-based Cutting Distance (km) Self-fluxing Stellite 0.05 to 0.2 0.1 to 1.0 alloy Work Material: Colmonoy No.6 (NiCr-based self-fluxing alloy) Insert: SNGN090308 Cutting Conditions: f=0.1mm/rev, ap=0.2mm, Dry ●BN7000 has a long service life with little wear, even in high speed cutting L ● Advantages of cutting heat resistant alloys with SUMIBORON SUMIBORON HEAT RESISTANT ALLOYS MACHINING Provides long tool life in the finishing of heat resistant alloys. ■ Recommended Grade ■ Recommended Cutting Conditions 400 Work Recommended Cutting Conditions Cutting Speed (m/min) BN350 Material Material vc(m/min) f ap 200 type 50 100 150 200 (mm/rev) (mm) 100 BN7000 Ni-based Inconel heart resistant 718 0.05 to 0.2 0.1 to 1.0 alloy 50 Carbide (Roughing med. Finishing) Co-based 30 heart resistant Stellite 0.05 to 0.2 0.1 to 1.0 alloy 0.1 0.2 0.3 0.4 Feed Rate (mm/rev) ●SUMIBORON is best suited for finishing of heat resistant alloy L10

Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo инструмент для отрезки

Каталог Sumitomo инструмент для отрезки Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal