Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron - страница 124

Навигация

- L001

- L002

- L003

- L004

- L005

- L006

- L007

- L008

- L009

- L010

- L011

- L012

- L013

- L014

- L015

- L016

- L017

- L018

- L019

- L020

- L021

- L022

- L023

- L024

- L025

- L026

- L027

- L028

- L029

- L030

- L031

- L032

- L033

- L034

- L035

- L036

- L037

- L038

- L039

- L040

- L041

- L042

- L043

- L044

- L045

- L046

- L047

- L048

- L049

- L050

- L051

- L052

- L053

- L054

- L055

- L056

- L057

- L058

- L059

- L060

- L061

- L062

- L063

- L064

- L065

- L066

- L067

- L068

- L069

- L070

- L071

- L072

- L073

- L074

- L075

- L076

- L077

- L078

- L079

- L080

- L081

- L082

- L083

- L084

- L085

- L086

- L087

- L088

- L089

- L090

- L091

- L092

- L093

- L094

- L095

- L096

- L097

- L098

- L099

- L100

- L101

- L102

- L103

- L104

- L105

- L106

- L107

- L108

- L109

- L110

- L111

- L112

- L113

- L114

- L115

- L116

- L117

- L118

- L119

- L120

- L121

- L122

- L123

- L124

- L125

- L126

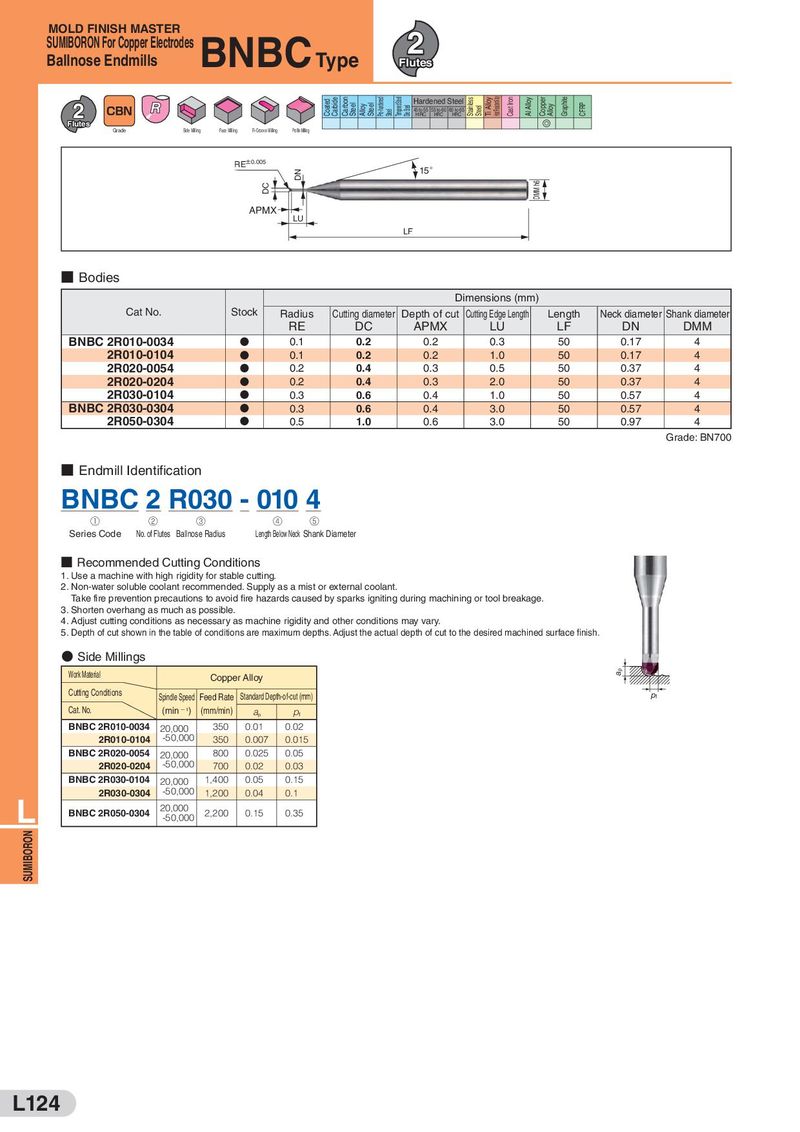

MOLD FINISH MASTER 2 BNBC SUMIBORON For Copper Electrodes Type Ballnose Endmills Flutes 2 Coated Carbide Carbon Steel Alloy Steel Pre-hardened Tempered Steel Die Steel Hardened Steel Stainless Ti Alloy Heat Resistant A loy Cast Iron Al Alloy Copper Alloy Graphite CFRP Steel 45 to 55 55 to 60 60 to 65 Steel HRC HRC HRC Flutes G Grade Side Milling Face Milling R-Groove Milling Profile Milling RE±0.005 15° DN DC DMM h6 APMX LU LF ■ Bodies Dimensions (mm) Cat No. Stock Radius Cutting diameter Depth of cut Cutting Edge Length Length Neck diameter Shank diameter RE DC APMX LU LF DN DMM BNBC 2R010-0034 D 0.1 0.2 0.2 0.3 50 0.17 4 2R010-0104 D 0.1 0.2 0.2 1.0 50 0.17 4 2R020-0054 D 0.2 0.4 0.3 0.5 50 0.37 4 2R020-0204 D 0.2 0.4 0.3 2.0 50 0.37 4 2R030-0104 D 0.3 0.6 0.4 1.0 50 0.57 4 BNBC 2R030-0304 D 0.3 0.6 0.4 3.0 50 0.57 4 2R050-0304 D 0.5 1.0 0.6 3.0 50 0.97 4 Grade: BN700 ■ Endmill Identification BNBC 2 R030 - 010 4 ① ② ③ ④ ⑤ Series Code No. of Flutes Ballnose Radius Length Below Neck Shank Diameter ■ Recommended Cutting Conditions 1. Use a machine with high rigidity for stable cutting. 2. Non-water soluble coolant recommended. Supply as a mist or external coolant. Take fire prevention precautions to avoid fire hazards caused by sparks igniting during machining or tool breakage. 3. Shorten overhang as much as possible. 4. Adjust cutting conditions as necessary as machine rigidity and other conditions may vary. 5. Depth of cut shown in the table of conditions are maximum depths. Adjust the actual depth of cut to the desired machined surface finish. ● Side Millings Work Material Copper Alloy ap Cutting Conditions Spindle Speed Feed Rate Standard Depth-of-cut (mm) pf Cat. No. (min ー 1) (mm/min) ap pf BNBC 2R010-0034 20,000 350 0.01 0.02 2R010-0104 -50,000 350 0.007 0.015 BNBC 2R020-0054 20,000 800 0.025 0.05 2R020-0204 -50,000 700 0.02 0.03 BNBC 2R030-0104 20,000 1,400 0.05 0.15 2R030-0304 -50,000 1,200 0.04 0.1 L BNBC 2R050-0304 20,000 2,200 0.15 0.35 -50,000 SUMIBORON L124

Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo инструмент для отрезки

Каталог Sumitomo инструмент для отрезки Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal