Каталог Sumitomo пластины с кубическим нитридом бора Sumiboron - страница 3

Навигация

- L001

- L002

- L003

- L004

- L005

- L006

- L007

- L008

- L009

- L010

- L011

- L012

- L013

- L014

- L015

- L016

- L017

- L018

- L019

- L020

- L021

- L022

- L023

- L024

- L025

- L026

- L027

- L028

- L029

- L030

- L031

- L032

- L033

- L034

- L035

- L036

- L037

- L038

- L039

- L040

- L041

- L042

- L043

- L044

- L045

- L046

- L047

- L048

- L049

- L050

- L051

- L052

- L053

- L054

- L055

- L056

- L057

- L058

- L059

- L060

- L061

- L062

- L063

- L064

- L065

- L066

- L067

- L068

- L069

- L070

- L071

- L072

- L073

- L074

- L075

- L076

- L077

- L078

- L079

- L080

- L081

- L082

- L083

- L084

- L085

- L086

- L087

- L088

- L089

- L090

- L091

- L092

- L093

- L094

- L095

- L096

- L097

- L098

- L099

- L100

- L101

- L102

- L103

- L104

- L105

- L106

- L107

- L108

- L109

- L110

- L111

- L112

- L113

- L114

- L115

- L116

- L117

- L118

- L119

- L120

- L121

- L122

- L123

- L124

- L125

- L126

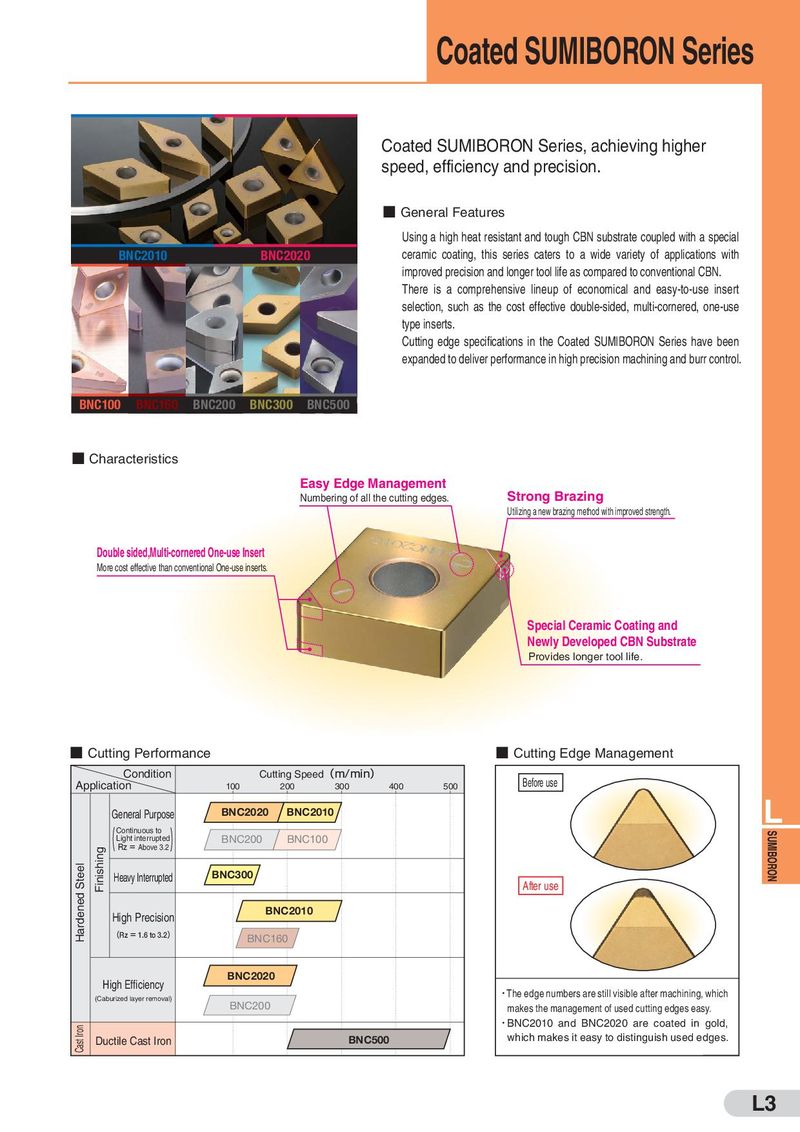

Coated SUMIBORON Series Coated SUMIBORON Series, achieving higher speed, efficiency and precision. ■ General Features Using a high heat resistant and tough CBN substrate coupled with a special BNC2010 BNC2020 ceramic coating, this series caters to a wide variety of applications with improved precision and longer tool life as compared to conventional CBN. There is a comprehensive lineup of economical and easy-to-use insert selection, such as the cost effective double-sided, multi-cornered, one-use type inserts. Cutting edge specifications in the Coated SUMIBORON Series have been expanded to deliver performance in high precision machining and burr control. BNC100 BNC160 BNC200 BNC300 BNC500 ■ Characteristics Easy Edge Management Numbering of all the cutting edges. Strong Brazing Utilizing a new brazing method with improved strength. Double sided,Multi-cornered One-use Insert More cost effective than conventional One-use inserts. Special Ceramic Coating and Newly Developed CBN Substrate Provides longer tool life. ■ Cutting Performance ■ Cutting Edge Management Condition Cutting Speed(m/min) Before use Application 100 200 300 400 500 General Purpose BNC2020 BNC2010 L (Continuous to ( SUMIBORON Light interrupted BNC200 BNC100 Finishing Rz = Above 3.2 Hardened Steel Heavy Interrupted BNC300 After use High Precision BNC2010 (Rz = 1.6 to 3.2) BNC160 BNC2020 High Efficiency ・The edge numbers are still visible after machining, which (Caburized layer removal) BNC200 makes the management of used cutting edges easy. Cast Iron ・BNC2010 and BNC2020 are coated in gold, Ductile Cast Iron BNC500 which makes it easy to distinguish used edges. L3

Каталог Sumitomo резьбонарезной инструмент

Каталог Sumitomo резьбонарезной инструмент Каталог Sumitomo инструмент для отрезки

Каталог Sumitomo инструмент для отрезки Каталог Sumitomo инструмент для обработки канавок

Каталог Sumitomo инструмент для обработки канавок Каталог Sumitomo модульные фрезерные системы

Каталог Sumitomo модульные фрезерные системы Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal