Каталог оснастка Dormer Pramet 2016 - страница 266

Навигация

- DIN 69871

- 69871-CC-OZ

- 69871-CC-ER

- 69871-CC-ER

- 69871-CC-ER

- 69871-CCM-ER

- 69871-CC-HKS

- 69871-W

- 69871-W

- 69871-W

- 69871-W-C

- 69871-W-C

- 69871-MT

- 69871-MTS

- 69871-RED-ISO

- 69871-FMH2

- 69871-FMH2

- 69871-FMH1

- 69871-FMH1

- 69871-FMH4

- 69871-DC

- 69871-QTCC

- 69871-QTCW

- 69871-HC

- 69871-HC

- 69871-SC

- 69871-SC

- 69871-SC

- 69871-SC

- 69871-SC-C

- 69871-IHA

- 69871-BLANKS

- 69871-TA

- ISO 60

- ISO-60-FMH1

- ISO-60-MT

- ISO-60-MTS

- ISO-60-RED-ISO

- MAS 403 BT

- BT-CC-OZ

- BT-CC-ER

- BT-CC-ER

- BT-CC-ER

- BT-CCM-ER

- BT-CC-HKS

- BT-W

- BT-W

- BT-W

- BT-W-C

- BT-W-C

- BT-MT

- BT-MTS

- BT-RED-ISO

- BT-FMH2

- BT-FMH2

- BT-FMH1

- BT-FMH1

- BT-FMH4

- BT-DC

- BT-QTCC

- BT-QTCW

- BT-HC

- BT-HC

- BT-SC

- BT-SC

- BT-SC

- BT-SC-C

- BT-IHA

- Bez názvu

- BT-TA

- DIN 2080

- 2080-CC-OZ

- 2080-CC-ER

- 2080-W

- 2080-W

- 2080-MT

- 2080-MTS

- 2080-RED-ISO

- 2080-FMH2

- 2080-FMH1

- 2080-DC

- 2080-QTCC

- 2080-BLANKS

- HSK-A

- HSK-A-CC-OZ

- HSK-A-CC-ER

- HSK-A-CCM-ER

- HSK-A-CC-HKS

- HSK-A-W

- HSK-A-W

- HSK-A-W-C

- HSK-A-FMH2

- HSK-A-FMH1

- HSK-A-FMH1

- HSK-A-FMH4

- HSK-A-MT

- HSK-A-MTS

- HSK-A-QTCC

- HSK-A-QTCW

- HSK-A-DC

- HSK-A-HC

- HSK-A-HC

- HSK-A-HC

- HSK-A-SC

- HSK-A-SC

- HSK-A-SC

- HSK-A-SC

- HSK-A-SC-C

- HSK-A-SC-C

- HSK-A-IHA

- HSK-A-BLANKS

- HSK-A-TA

- VDI

- VDI-B1

- VDI-B2

- VDI-B3

- VDI-B4

- VDI-B5

- VDI-B6

- VDI-B7

- VDI-B8

- VDI-C1

- VDI-C2

- VDI-C3

- VDI-C4

- VDI-D1

- VDI-D2

- VDI-AR

- VDI-AL

- VDI-E1

- VDI-E2

- VDI-E3

- VDI-E4

- VDI-F1

- VDI-HC

- VDI-Z2-S

- VDI-Z2-P

- VDI-DC

- VDI-DC-C

- VDI-QTCC

- VDI-QTCW

- VDI-A1

- VDI-A2

- VDI-TA

- MORSE

- MORSE-CC-ER

- MORSE-FMH2

- MORSE-QTCC

- MORSE-RED-MT

- MORSE-DC

- ADAPTORS / ADAPTÉRY ПЕРЕХОДНИК / 转接套

- AC-CC-ER

- ACF-CC-ER

- ACF-CC-ER-HX

- ACF-CCM-ER

- ACF-CCM-ER

- ACF-CCM-ER-D

- AC-HC

- AC-SC

- AW-DC

- AW-QTCC

- AW-QTCW

- AW-RED-W

- ACCESSORIES / PŘÍSLUŠENSTVÍ АКСЕССУАРЫ / 附件

- PS-69872

- PS-7388

- PS-BT

- PS-BT-C-S

- PS-2080-C

- OZ-C

- OZ-C-P

- OZ-C-SET-WP

- OZ-C-SET-WB

- OZ-C-SET-P-WP

- OZ-C-SET-P-WB

- ER-C

- ER-C-P

- ER-C-S

- ER-C-SC4

- ER-T

- ER-T-SC4

- ER-C-SET-WP

- ER-C-SET-WB

- ER-C-SET-P-WP

- ER-C-SET-P-WB

- ER-C-SET-S-WP

- ER-C-SET-S-WB

- ER-C-SET-SC4-WP

- ER-C-SET-SC4-WB

- ER-T-SET-WP

- ER-T-SET-WB

- ER-T-SET-SC4-WP

- ER-T-SET-SC4-WB

- HC-C

- HC-C-S

- QTCW-1

- QTCW-2

- QTCW-3

- QTCC-1

- QTCC-2

- QTCC-3

- QTCR

- HKS-C

- HKS-C-S

- N-OZ

- N-OZ-SR

- SR-OZ

- N-ER-M

- N-ER

- N-ER-SR

- N-ER-SR-SN

- SR-ER

- K-HKS

- K-OZ

- K-ER

- K-ER-M

- K-FMH

- E-MORSE

- E-HKS

- S-FMH

- S-FMH-C

- S-W

- F-FMH2

- DR-FMH2

- DS-FMH4

- S-DS-FMH4

- CT-HSK-A

- K-CT-HSK-A

- VDI-RS-E2

- VDI-SHIMS

- VDI-NOZZ

- TW

- AB-A360

- AB-S90

- TECHNICAL PART

- Steep Taper

- Pull studs

- HSK (hollow taper shanks)

- HSK coolant tubes

- Effects of imbalance on machine spindles, toolholders and tools

- Hydraulic expansion chucks

- Operating and user instructions for hydraulic expansion chucks

- Torques for clamping end-mills in end mill holders DIN 6359

- Operating and user instructions for CNC-drill chucks

- Mounting instructions for ER-Collets per DIN STD 6499

- Mounting instruction for sealing discs

- Quick-change tapping chucks

- Instructions for tapping chucks

- Screw taps-shaft size

- Tool assignment for disc turrets

- High-performance milling chucks HKS-system

- Product codes description

- TECHNICKÁ ČÁST

- STRMÝ KUŽEL

- TAŽNÉ ČEPY

- HSK (duté kuželové stopky)

- TRUBICE PRO ŘEZNOU KAPALINU HSK

- ÚČINKY NEROVNOVÁHY NA VŘETENA, DRŽÁKY A NÁSTROJE

- ÚČINKY NEROVNOVÁHY NA VŘETENA, DRŽÁKY A NÁSTROJE

- HYDROUPÍNAČE

- NÁVOD K OBSLUZE PRO HYDROUPÍNAČE

- UTAHOVACÍ MOMENTY ŠROUBŮ PRO UPNUTÍ STOPKOVÝCH FRÉZ V DRŽÁCÍCH DIN 6359

- NÁVOD K OBSLUZE PRO NC VRTACÍ HLAVIČKY

- NÁVOD K MONTÁŽI PRO KLEŠTINOVÉ UPÍNAČE ER PODLE DIN STD 6499

- NÁVOD K MONTÁŽI PRO TĚSNICÍ KROUŽKY

- RYCHLOVÝMĚNNÉ KLEŠTINOVÉ UPÍNAČE PRO ZÁVITOVÁNÍ

- NÁVOD PRO RYCHLOVÝMĚNNÉ ZÁVITOVACÍ UPÍNAČE

- TABULKA ČTYŘHRANŮ STOPEK ZÁVITNÍKŮ

- ZNAČENÍ A ORIENTACE DRŽÁKŮ VDI V REVOLVEROVÝCH HLAVÁCH

- SYSTÉM HKS SE SILOVÝMI UPÍNACÍMI POUZDRY

- POPISY KÓDŮ VÝROBKŮ

- ТЕХНИЧЕСКАЯ ЧАСТЬ

- КОНУС SK

- ШТРЕВЕЛИ

- КОНУС HSK (от англ. hollow taper shanks – полый конус)

- КОНУС HSK (от англ. hollow taper shanks – полый конус)

- Патрубки для подачи СОЖ к оправкам HSK

- ЭФФЕКТ ДИСБАЛАНСА ШПИНДЕЛЯ СТАНКА,ОПРАВОК И РЕЖУЩЕГО ИНСТРУМЕНТА

- ЭФФЕКТ ДИСБАЛАНСА ШПИНДЕЛЯ СТАНКА,ОПРАВОК И РЕЖУЩЕГО ИНСТРУМЕНТА

- ГИДРАВЛИЧЕСКИЕ ПАТРОНЫ

- ИНСТРУКЦИЯ ПО ЭКСПЛУАТАЦИИ ГИДРАВЛИЧЕСКИХ ПАТРОНОВ

- МОМЕНТЫ ЗАТЯЖКИ КОНЦЕВЫХ ФРЕЗ В ОПРАВКАХ ПО DIN 6359

- Инструкции по эксплуатации сверлильных патронов для станков с ЧПУ

- ИНСТРУКЦИИ ПО УСТАНОВКЕ ЦАНГ ER ПО DIN STD 6499

- ИНСТРУКЦИЯ ПО УСТАНОВКЕ УПЛОТНИТЕЛЬНЫХ КОЛЕЦ

- БЫСТРОСМЕННЫЕ РЕЗЬБОНАРЕЗНЫЕ ПАТРОНЫ

- ИНСТРУКЦИЯ ДЛЯ РЕЗЬБОНАРЕЗНЫХ ПАТРОНОВ

- СООТВЕТСТВИЕ РАЗМЕРА РЕЗЬБЫ И РАЗМЕРА ХВОСТОВИКА МЕТЧИКА

- ПРИМЕНЕНИЕ ИНСТРУМЕНТА В ДИСКОВОЙ РЕВОЛЬВЕРНОЙ ГОЛОВКЕ

- ВЫСОКОПРОИЗВОДИТЕЛЬНЫЕ ФРЕЗЕНЫЕ ОПРАВКИ СИСТЕМЫ HKS

- СИСТЕМА ОБОЗНАЧЕНИЯ

- 技术部分

- 锥柄

- 拉钉

- HSK(中空锥形柄)

- HSK冷却液管

- 不平衡对机床主轴、刀架和刀具的影响

- 不平衡对机床主轴、刀架和刀具的影响

- 液压刀柄

- 液压刀柄操作和使用说明

- 侧固刀柄(DIN 6359)端面铣刀夹紧扭矩

- CNC钻卡头操作和使用说明

- ER夹头安装说明,依照DIN STD 6499

- 密封圈安装说明

- 快速更换式攻丝卡盘

- 攻丝卡盘说明

- 攻丝-轴尺寸

- 盘塔刀具分配

- 强力刀柄HKS系统

- 产品代码描述

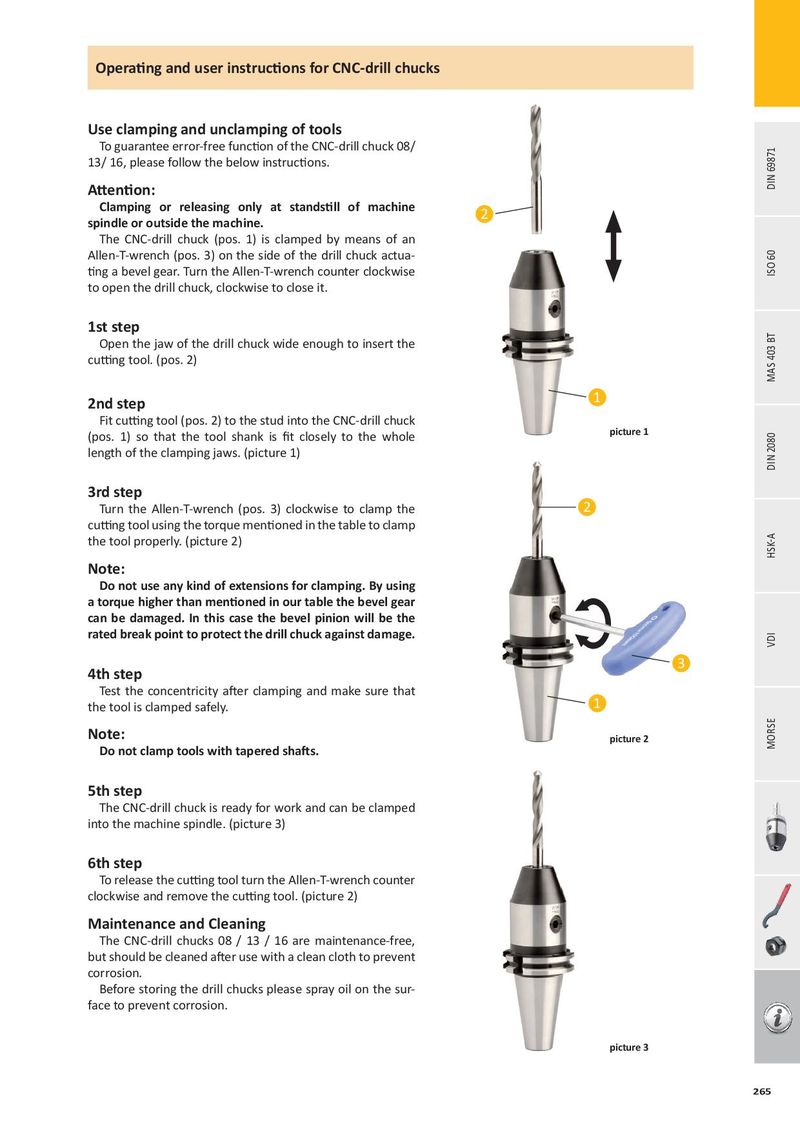

Operating and user instructions for CNC-drill chucks Use clamping and unclamping of tools To guarantee error-free function of the CNC-drill chuck 08/ 13/ 16, please follow the below instructions. DIN 69871 Attention: Clamping or releasing only at standstill of machine ❷ spindle or outside the machine. The CNC-drill chuck (pos. 1) is clamped by means of an Allen-T-wrench (pos. 3) on the side of the drill chuck actua- ting a bevel gear. Turn the Allen-T-wrench counter clockwise ISO 60 to open the drill chuck, clockwise to close it. 1st step Open the jaw of the drill chuck wide enough to insert the cutting tool. (pos. 2) MA S 403 BT ❶ 2nd step Fit cutting tool (pos. 2) to the stud into the CNC-drill chuck picture 1 (pos. 1) so that the tool shank is fit closely to the whole length of the clamping jaws. (picture 1) DIN 2080 3rd step Turn the Allen-T-wrench (pos. 3) clockwise to clamp the ❷ cutting tool using the torque mentioned in the table to clamp the tool properly. (picture 2) HSK-A Note: Do not use any kind of extensions for clamping. By using a torque higher than mentioned in our table the bevel gear can be damaged. In this case the bevel pinion will be the rated break point to protect the drill chuck against damage. VDI ❸ 4th step Test the concentricity after clamping and make sure that the tool is clamped safely. ❶ Note: picture 2 MORSE Do not clamp tools with tapered shafts. 5th step The CNC-drill chuck is ready for work and can be clamped into the machine spindle. (picture 3) 6th step To release the cutting tool turn the Allen-T-wrench counter clockwise and remove the cutting tool. (picture 2) Maintenance and Cleaning The CNC-drill chucks 08 / 13 / 16 are maintenance-free, but should be cleaned after use with a clean cloth to prevent corrosion. Before storing the drill chucks please spray oil on the sur- face to prevent corrosion. picture 3 265

Общий каталог Dormer Pramet 2018

Общий каталог Dormer Pramet 2018 Каталог Dormer Pramet токарная обработка 2021 - 2022

Каталог Dormer Pramet токарная обработка 2021 - 2022 Брошюра Dormer Pramet новинки 2021

Брошюра Dormer Pramet новинки 2021 Каталог Dormer Pramet обработка резьбы 2021 - 2022

Каталог Dormer Pramet обработка резьбы 2021 - 2022 Каталог Dormer Pramet фрезерование 2021 - 2022

Каталог Dormer Pramet фрезерование 2021 - 2022