Техническая информация Sumitomo - страница 8

Навигация

Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Каталог Sumitomo твердосплавные пластины

Каталог Sumitomo твердосплавные пластины Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Technical Guidance

Basics of Milling Milling Edition

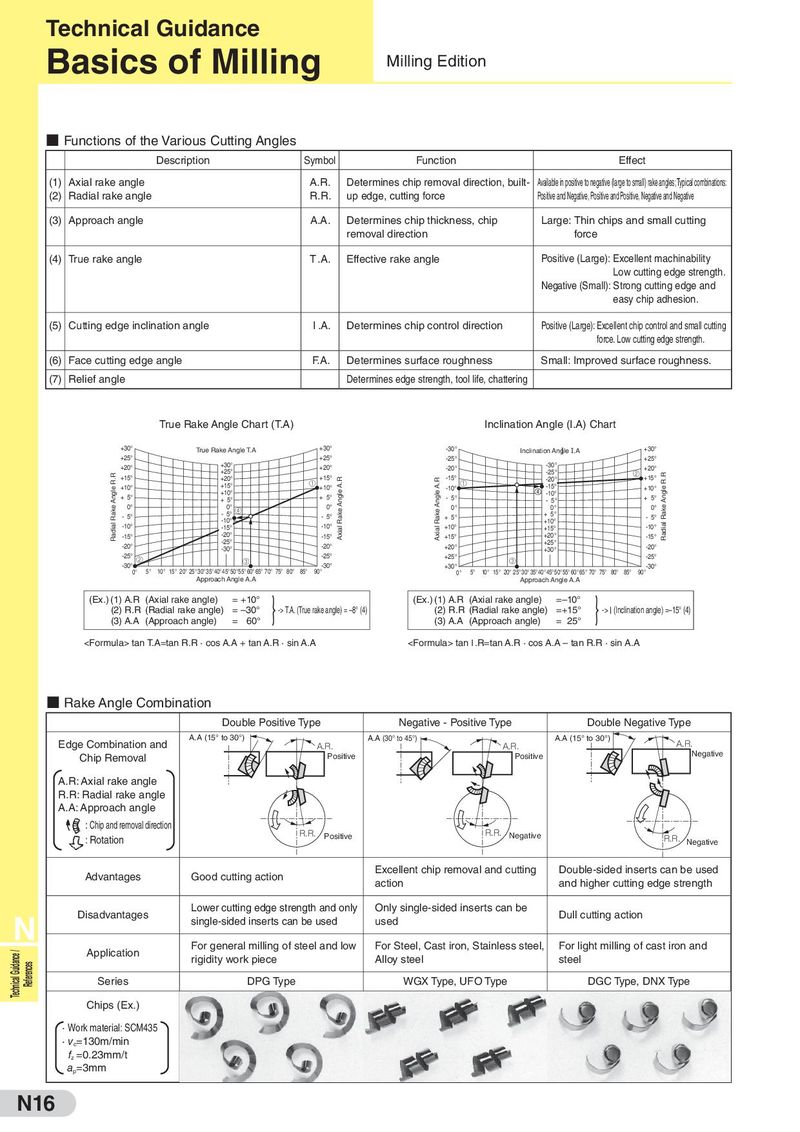

■ Functions of the Various Cutting Angles

Description Symbol Function Effect

(1) Axial rake angle A.R. Determines chip removal direction, built- Available in positive to negative (large to small) rake angles; Typical combinations:

(2) Radial rake angle R.R. up edge, cutting force Positive and Negative, Positive and Positive, Negative and Negative

(3) Approach angle A.A. Determines chip thickness, chip Large: Thin chips and small cutting

removal direction force

(4) True rake angle T .A. Effective rake angle Positive (Large): Excellent machinability

Low cutting edge strength.

Negative (Small): Strong cutting edge and

easy chip adhesion.

(5) Cutting edge inclination angle I .A. Determines chip control direction Positive (Large): Excellent chip control and small cutting

force. Low cutting edge strength.

(6) Face cutting edge angle F.A. Determines surface roughness Small: Improved surface roughness.

(7) Relief angle Determines edge strength, tool life, chattering

True Rake Angle Chart (T.A) Inclination Angle (I.A) Chart

+30° True Rake Angle T.A +30° -30° Inclination Angle I.A +30°

+25° +25° -25° +25°

+20° +30° +20° -20° -30° +20°

Radial Rake Angle R.R +15° +25° +15° -25° ② Radial Rake Angle R.R

+20° ① Axial Rake Angle A.R Axial Rake Angle A.R -15° -20° +15°

-10° ①

+10° +15° +10° -15° +10°

+ 5° +10° + 5° - 5° -10° + 5°

+ 5° - 5°

0° 0° ④ 0° 0° 0° 0°

- 5° - 5° - 5° + 5° + 5° - 5°

-10° -10° -10° +10°

-15° +10° +15° -10°

-15° -20° -15° +15° +20° -15°

-20° -25° -20° +20° +25° -20°

-30° +30°

-25° ② ③ -25° +25° ③ -25°

-30° 5° 10° 15° 20° 25° 30° 35°40°45°50°55° 60° 65° 70° 75° 80° 85° 90°-30° +30° -30°

0° 0° 5° 10° 15° 20° 25° 30° 35°40°45°50°55° 60° 65° 70° 75° 80° 85° 90°

Approach Angle A.A Approach Angle A.A

(Ex.) (1) A.R (Axial rake angle) = +10° }-> T.A. (Ex.) (1) A.R (Axial rake angle) =–10° }-> I (Inclination angle)

(2) R.R (Radial rake angle) = –30° (True rake angle) = –8° (4) (2) R.R (Radial rake angle) =+15° =–15° (4)

(3) A.A (Approach angle) = 60° (3) A.A (Approach angle) = 25°