Техническая информация Sumitomo - страница 21

Навигация

Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Каталог Sumitomo твердосплавные пластины

Каталог Sumitomo твердосплавные пластины Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

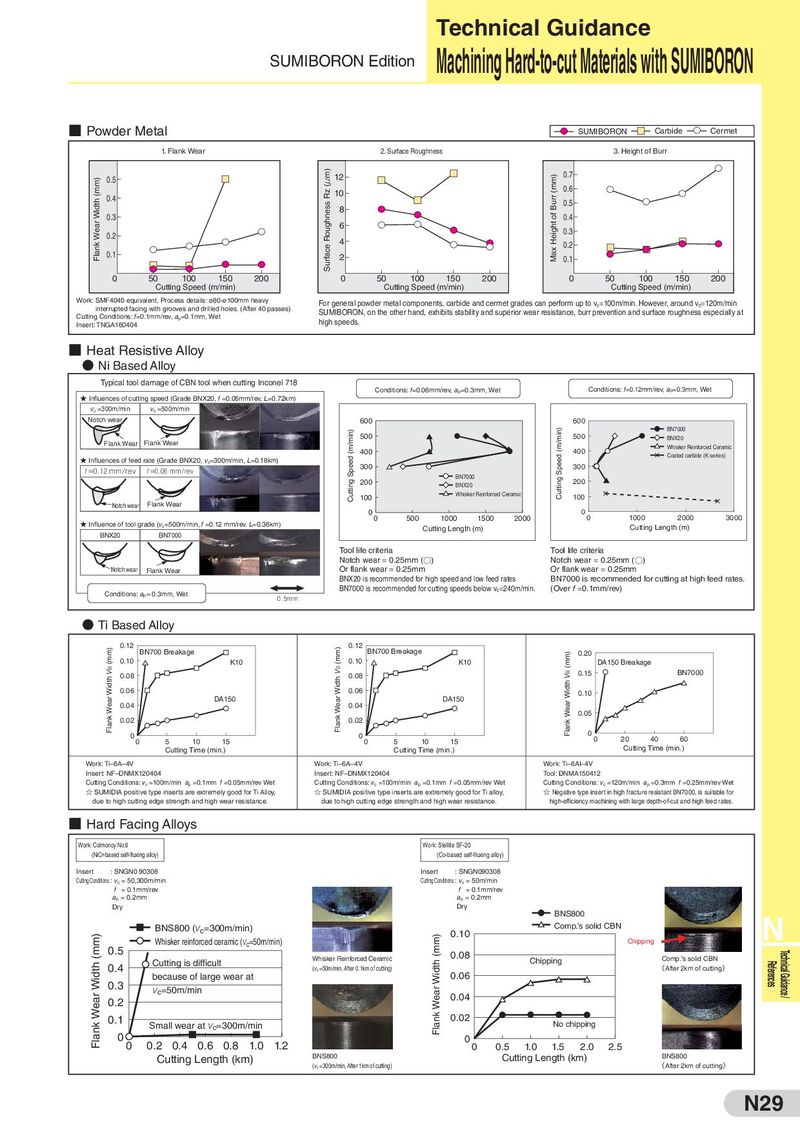

Technical Guidance SUMIBORON Edition Machining Hard-to-cut Materials with SUMIBORON ■ Powder Metal D SUMIBORON ■ Carbide D Cermet 1. Flank Wear 2. Surface Roughness 3. Height of Burr Surface Roughness Rz (μm) ■ 0.7 D Flank Wear Width (mm) 0.5 ■ 12 ■ Max Height of Burr (mm) 10 0.6 D D 0.4 ■ 0.5 D 8 D D 0.3 0.4 6 D D D 0.3 0.2 D D D 4 D DD 0.2 ■ D■ D 0.1 D D ■D D D 2 0.1 ■D ■D 0 50 100 150 200 0 50 100 150 200 0 50 100 150 200 Cutting Speed (m/min) Cutting Speed (m/min) Cutting Speed (m/min) Work: SMF4040 equivalent, Process details: ø80-ø100mm heavy For general powder metal components, carbide and cermet grades can perform up to vc=100m/min. However, around vc=120m/min interrupted facing with grooves and drilled holes. (After 40 passes) SUMIBORON, on the other hand, exhibits stability and superior wear resistance, burr prevention and surface roughness especially at Cutting Conditions: f=0.1mm/rev, ap=0.1mm, Wet high speeds. Insert: TNGA160404 ■ Heat Resistive Alloy ● Ni Based Alloy Typical tool damage of CBN tool when cutting Inconel 718 Conditions: f=0.06mm/rev, ap=0.3mm, Wet Conditions: f=0.12mm/rev, ap=0.3mm, Wet ★ Influences of cutting speed (Grade BNX20, f =0.06mm/rev, L=0.72km) vc =300m/min vc =500m/min Notch wear 600 600 Cutting Speed (m/min) Cutting Speed (m/min) BN7000 500 500 BNX20 Flank Wear Flank Wear Whisker Reinforced Ceramic 400 400 Coated carbide (K series) ★ Influences of feed rate (Grade BNX20, vc=300m/min, L=0.18km) 300 300 f =0.12 mm/rev f =0.06 mm/rev BN7000 200 BNX20 200 100 Whisker Reinforced Ceramic 100 Notch wear Flank Wear 0 0 0 1000 2000 3000 ★ Influence of tool grade (vc=500m/min, f =0.12 mm/rev. L=0.36km) 0 500 1000 1500 2000 Cutting Length (m) Cutting Length (m) BNX20 BN7000 Tool life criteria Tool life criteria Notch wear = 0.25mm (○) Notch wear = 0.25mm (○) Notch wear Flank Wear Or flank wear = 0.25mm Or flank wear = 0.25mm BNX20 is recommended for high speed and low feed rates BN7000 is recommended for cutting at high feed rates. Conditions: ap= 0.3mm, Wet BN7000 is recommended for cutting speeds below vc=240m/min. (Over f =0.1mm/rev) 0.5mm ● Ti Based Alloy Flank Wear Width VB (mm) 0.12 BN700 Breakage Flank Wear Width VB (mm) 0.12 BN700 Breakage Flank Wear Width VB (mm) 0.20 0.10 K10 0.10 K10 DA150 Breakage 0.08 0.08 0.15 BN7000 0.06 0.06 0.10 0.04 DA150 0.04 DA150 0.05 0.02 0.02 0 0 0 0 20 40 60 0 5 10 15 0 5 10 15 Cutting Time (min.) Cutting Time (min.) Cutting Time (min.) Work: Ti–6A–4V Work: Ti–6A–4V Work: Ti–6AI–4V Insert: NF–DNMX120404 Insert: NF–DNMX120404 Tool: DNMA150412 Cutting Conditions: vc =100m/min ap =0.1mm f =0.05mm/rev Wet Cutting Conditions: vc =100m/min ap =0.1mm f =0.05mm/rev Wet Cutting Conditions: vc =120m/min ap =0.3mm f =0.25mm/rev Wet ☆ SUMIDIA positive type inserts are extremely good for Ti Alloy, ☆ SUMIDIA positive type inserts are extremely good for Ti alloy, ☆ Negative type insert in high fracture resistant BN7000, is suitable for due to high cutting edge strength and high wear resistance. due to high cutting edge strength and high wear resistance. high-efficiency machining with large depth-of-cut and high feed rates. ■ Hard Facing Alloys Work: Colmonoy No.6 Work: Stellite SF-20 (NiCr-based self-fluxing alloy) (Co-based self-fluxing alloy) Insert : SNGN0 90308 Insert : SNGN090308 Cutting Conditions : vc = 50,300m/min Cutting Conditions : vc = 50m/min f = 0.1mm/rev f = 0.1mm/rev ap = 0.2mm ap = 0.2mm Dry Dry BNS800 N BNS800 ( c=300m/min) Comp.’s solid CBN Flank Wear Width (mm) Whisker reinforced ceramic ( c=50m/min) Flank Wear Width (mm) 0.10 Chipping 0.5 Whisker Reinforced Ceramic 0.08 Comp.'s solid CBN Technical Guidance / 0.4 Cutting is difficult Chipping References (vc =50m/min, After 0.1km of cutting) (After 2km of cutting) because of large wear at 0.06 0.3 c=50m/min 0.2 0.04 0.1 Small wear at c=300m/min 0.02 No chipping 0 0 0.2 0.4 0.6 0.8 1.0 1.2 0 0 0.5 1.0 1.5 2.0 2.5 Cutting Length (km) BNS800 Cutting Length (km) BNS800 (vc =300m/min, After 1km of cutting) (After 2km of cutting) N29