Техническая информация Sumitomo - страница 19

Навигация

Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Каталог Sumitomo твердосплавные пластины

Каталог Sumitomo твердосплавные пластины Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

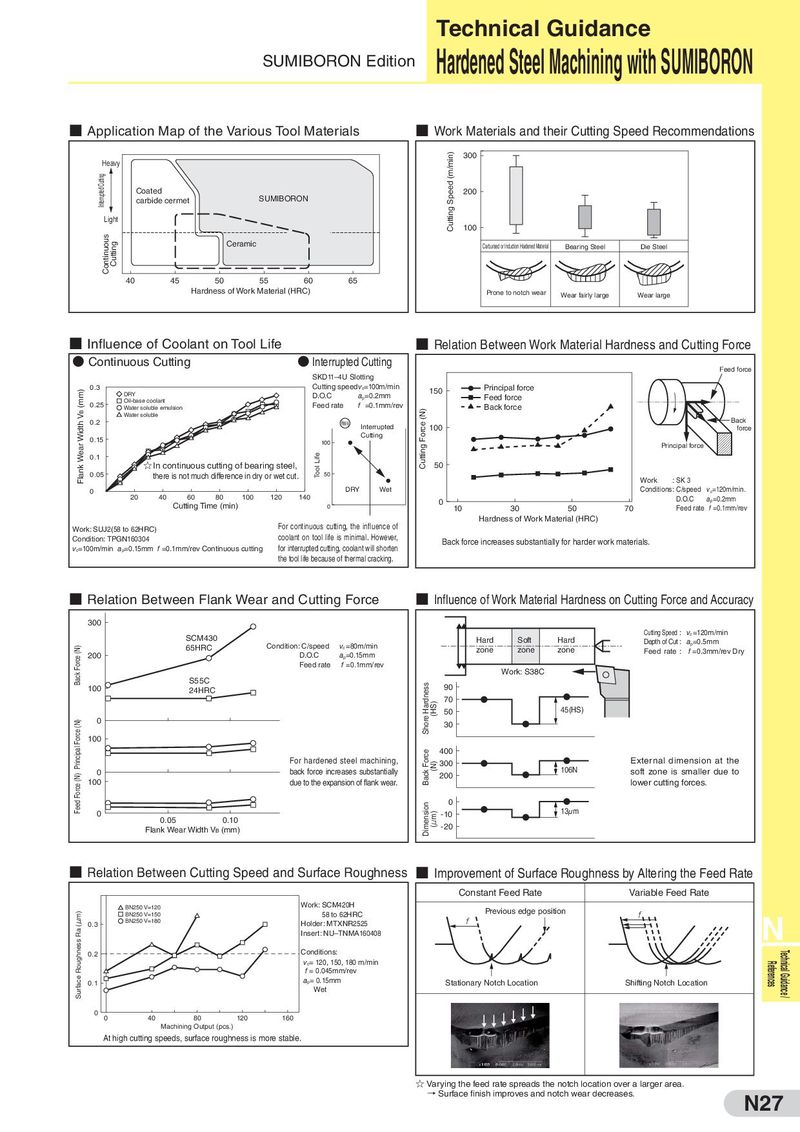

Technical Guidance SUMIBORON Edition Hardened Steel Machining with SUMIBORON ■ Application Map of the Various Tool Materials ■ Work Materials and their Cutting Speed Recommendations Cutting Speed (m/min) 300 Heavy Interrupted Cutting Coated 200 carbide cermet SUMIBORON Light 100 Continuous Cutting Ceramic Carburised or Induction Hardened Material Bearing Steel Die Steel 40 45 50 55 60 65 Hardness of Work Material (HRC) Prone to notch wear Wear fairly large Wear large ■ Influence of Coolant on Tool Life ■ Relation Between Work Material Hardness and Cutting Force ● Continuous Cutting ● Interrupted Cutting Feed force SKD11–4U Slotting Flank Wear Width VB (mm) 0.3 Cutting speedvc=100m/min 150 Principal force DRY D.O.C ap=0.2mm Feed force 0.25 Oil-base coolant Feed rate f =0.1mm/rev Water soluble emulsion (N) Back force Water soluble Back 0.2 Heavy Interrupted Force 100 force 0.15 Cutting 100 Cutting Principal force 0.1 Tool Life ☆ In continuous cutting of bearing steel, 50 0.05 there is not much difference in dry or wet cut. 50 Work : SK 3 0 DRY Wet Conditions: C/speed vc=120m/min. 20 40 60 80 100 120 140 0 D.O.C ap=0.2mm Cutting Time (min) 0 10 30 50 70 Feed rate f =0.1mm/rev Hardness of Work Material (HRC) Work: SUJ2(58 to 62HRC) For continuous cutting, the influence of Condition: TPGN160304 coolant on tool life is minimal. However, Back force increases substantially for harder work materials. vc=100m/min ap=0.15mm f =0.1mm/rev Continuous cutting for interrupted cutting, coolant will shorten the tool life because of thermal cracking. ■ Relation Between Flank Wear and Cutting Force ■ Influence of Work Material Hardness on Cutting Force and Accuracy 300 SCM430 Cutting Speed : vc =120m/min Condition: C/speed vc =80m/min Hard Soft Hard Depth of Cut : ap=0.5mm Back Force (N) 65HRC zone zone zone Feed rate : f =0.3mm/rev Dry 200 D.O.C ap=0.15mm Feed rate f =0.1mm/rev Work: S38C S55C Shore Hardness 90 100 24HRC (HS) 70 50 45(HS) Feed Force (N) Principal Force (N) 0 30 100 Back Force 400 For hardened steel machining, (N) 300 External dimension at the 0 back force increases substantially 200 106N soft zone is smaller due to 100 due to the expansion of flank wear. lower cutting forces. Dimension 0 0 (μm) -10 13μm 0.05 0.10 -20 Flank Wear Width VB (mm) ■ Relation Between Cutting Speed and Surface Roughness ■ Improvement of Surface Roughness by Altering the Feed Rate Constant Feed Rate Variable Feed Rate BN250 V=120 Work: SCM420H Previous edge position Surface Roughness Ra (μm) BN250 V=150 58 to 62HRC N 0.3 BN250 V=180 Holder: MTXNR2525 Insert: NU–TNMA160408 0.2 Conditions: Technical Guidance / vc= 120, 150, 180 m/min References f = 0.045mm/rev 0.1 ap= 0.15mm Stationary Notch Location Shifting Notch Location Wet 0 0 40 80 120 160 Machining Output (pcs.) At high cutting speeds, surface roughness is more stable. ☆ Varying the feed rate spreads the notch location over a larger area. → Surface finish improves and notch wear decreases. N27