Техническая информация Sumitomo - страница 5

Навигация

Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Каталог Sumitomo твердосплавные пластины

Каталог Sumitomo твердосплавные пластины Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

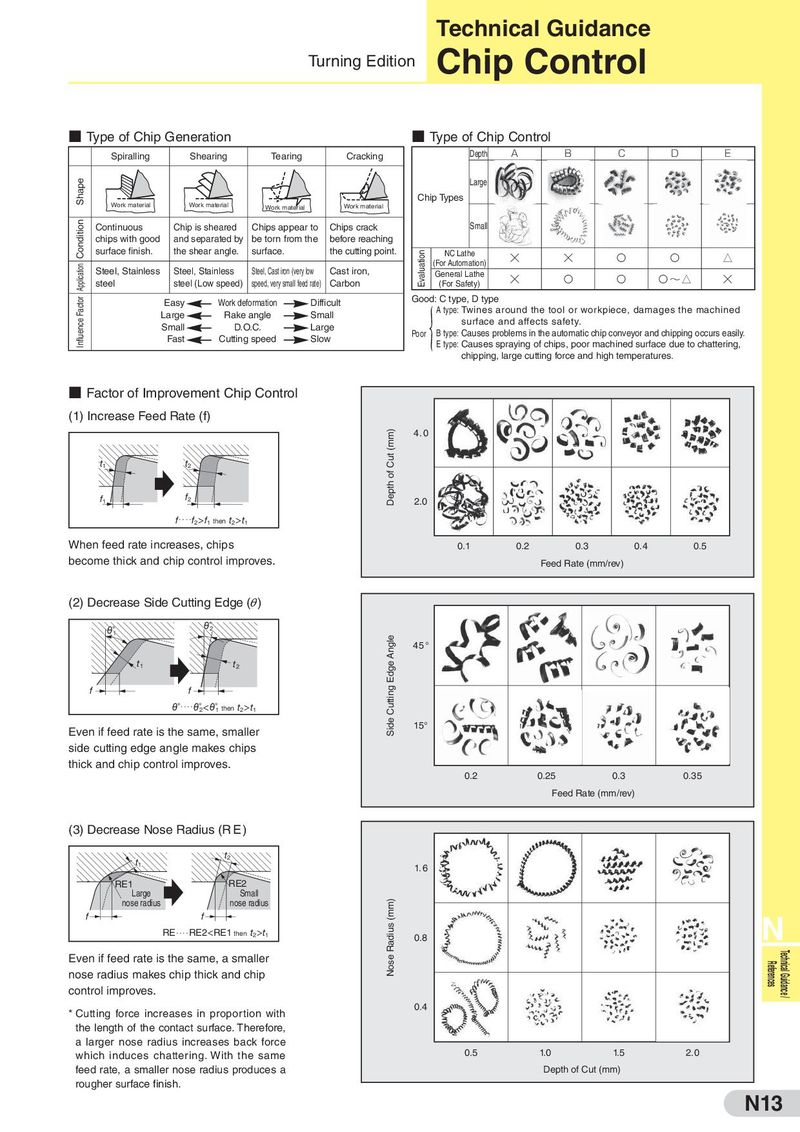

Technical Guidance Turning Edition Chip Control ■ Type of Chip Generation ■ Type of Chip Control Spiralling Shearing Tearing Cracking Depth A B C D E Shape Large Chip Types Work material Work material Work material Work material Application Condition Continuous Chip is sheared Chips appear to Chips crack Small chips with good and separated by be torn from the before reaching surface finish. the shear angle. surface. the cutting point. Evaluation NC Lathe H H S S J (For Automation) Steel, Stainless Steel, Stainless Steel, Cast iron (very low Cast iron, General Lathe H S S S〜J H steel steel (Low speed) speed, very small feed rate) Carbon (For Safety) Influence Factor Easy Work deformation Difficult Good: C type, D type Large Rake angle Small {Poor A type: Twines around the tool or workpiece, damages the machined Small D.O.C. Large surface and affects safety. Fast Cutting speed Slow B type: Causes problems in the automatic chip conveyor and chipping occurs easily. E type: Causes spraying of chips, poor machined surface due to chattering, chipping, large cutting force and high temperatures. ■ Factor of Improvement Chip Control (1) Increase Feed Rate (f) Depth of Cut (mm) 4.0 t11 t22 f1 f2 2.0 f‥‥f2>f1 then t2>t1 When feed rate increases, chips 0.1 0.2 0.3 0.4 0.5 become thick and chip control improves. Feed Rate (mm/rev) (2) Decrease Side Cutting Edge (θ ) θ:1 θ:2 Side Cutting Edge Angle 45° t1 t2 f f :‥‥:2<:1 then t2>t1 Even if feed rate is the same, smaller 15° side cutting edge angle makes chips thick and chip control improves. 0.2 0.25 0.3 0.35 Feed Rate (mm/rev) (3) Decrease Nose Radius (R E ) t11 t22 1. 6 RE1 RE2 Large Small nose radius nose radius Nose Radius (mm) f f N RE‥‥RE2<RE1 then t2>t1 0.8 Even if feed rate is the same, a smaller References Technical Guidance / nose radius makes chip thick and chip control improves. * Cutting force increases in proportion with 0.4 the length of the contact surface. Therefore, a larger nose radius increases back force which induces chattering. With the same 0.5 1.0 1.5 2.0 feed rate, a smaller nose radius produces a Depth of Cut (mm) rougher surface finish. N13