Техническая информация Sumitomo - страница 12

Навигация

Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Каталог Sumitomo твердосплавные пластины

Каталог Sumitomo твердосплавные пластины Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

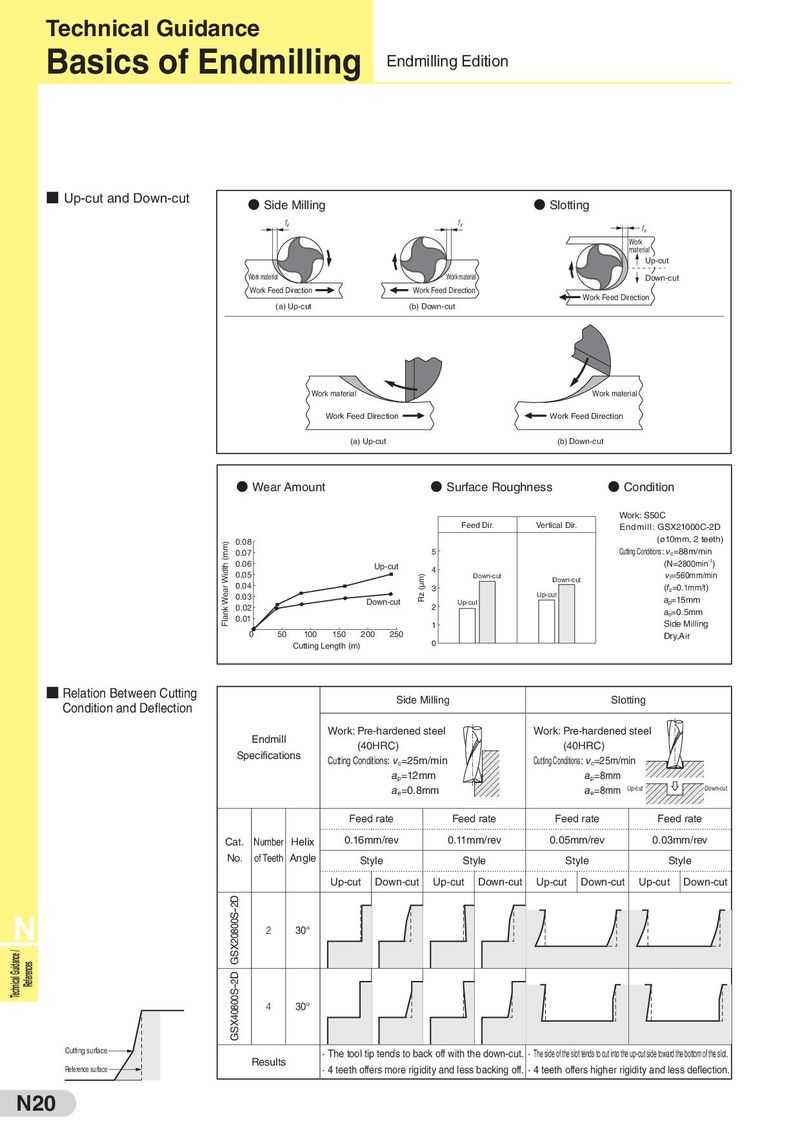

Technical Guidance Basics of Endmilling Endmilling Edition ■ Up-cut and Down-cut ● Side Milling ● Slotting fz fz fz Work material Up-cut Work material Work material Down-cut Work Feed Direction Work Feed Direction Work Feed Direction (a) Up-cut (b) Down-cut Work material Work material Work Feed Direction Work Feed Direction (a) Up-cut (b) Down-cut ● Wear Amount ● Surface Roughness ● Condition Work: S50C Feed Dir. Vertical Dir. Endmill: GSX21000C-2D Flank Wear Width (mm) 0.08 (ø10mm, 2 teeth) 0.07 5 Cutting Conditions: vc=88m/min 0.06 Up-cut 4 (N=2800min-1) 0.05 Rz (μm) Down-cut Down-cut vf=560mm/min 0.04 3 (fz=0.1mm/t) 0.03 Up-cut ap=15mm 0.02 Down-cut 2 Up-cut 0.01 ae=0.5mm 1 Side Milling 0 50 100 150 200 250 Dry,Air Cutting Length (m) 0 ■ Relation Between Cutting Side Milling Slotting Condition and Deflection Endmill Work: Pre-hardened steel Work: Pre-hardened steel (40HRC) (40HRC) Specifications Cutting Conditions: vc=25m/min Cutting Conditions: vc=25m/min ap=12mm ap=8mm ae=0.8mm ae=8mm Up-cut Down-cut Feed rate Feed rate Feed rate Feed rate Cat. Number Helix 0.16mm/rev 0.11mm/rev 0.05mm/rev 0.03mm/rev No. of Teeth Angle Style Style Style Style Up-cut Down-cut Up-cut Down-cut Up-cut Down-cut Up-cut Down-cut N GSX20800S-2D 2 30° Technical Guidance / References GSX40800S-2D 4 30° Cutting surface · The tool tip tends to back off with the down-cut. · The side of the slot tends to cut into the up-cut side toward the bottom of the slot. Reference surface Results · 4 teeth offers more rigidity and less backing off. · 4 teeth offers higher rigidity and less deflection. N20