Техническая информация Sumitomo - страница 13

Навигация

Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Каталог Sumitomo твердосплавные пластины

Каталог Sumitomo твердосплавные пластины Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

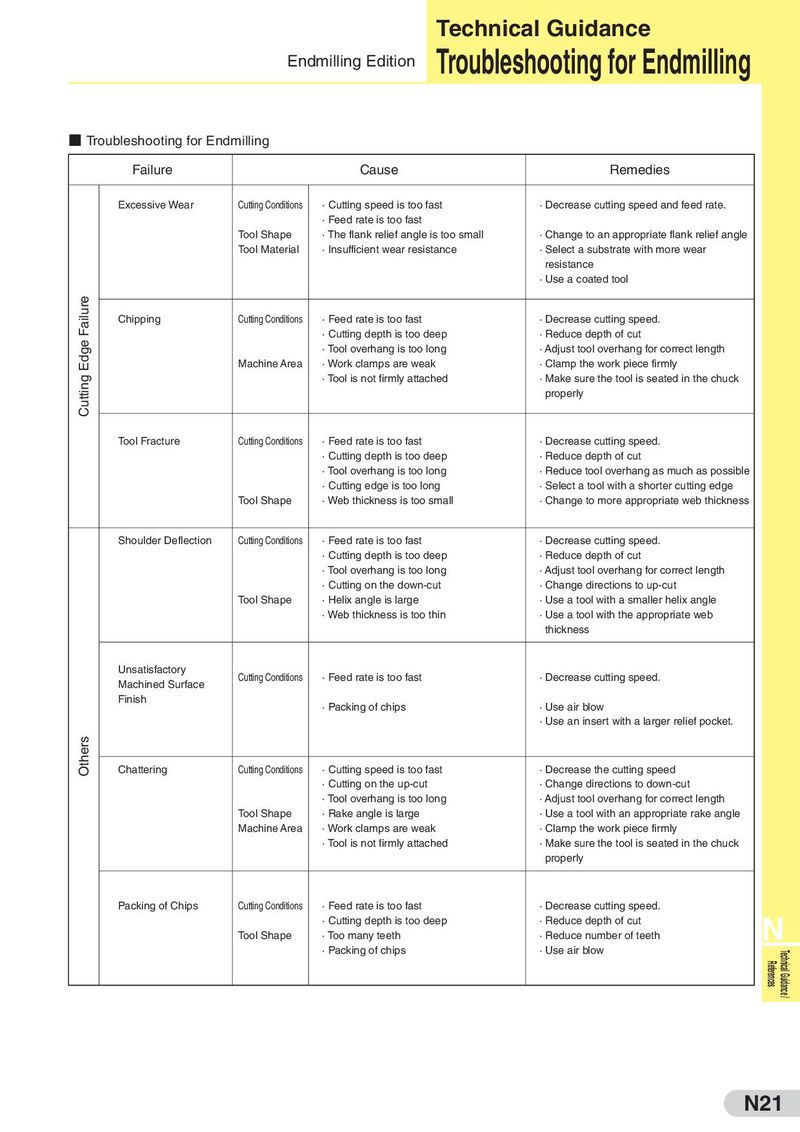

Technical Guidance Endmilling Edition Troubleshooting for Endmilling ■ Troubleshooting for Endmilling Failure Cause Remedies Excessive Wear Cutting Conditions · Cutting speed is too fast · Decrease cutting speed and feed rate. · Feed rate is too fast Tool Shape · The flank relief angle is too small · Change to an appropriate flank relief angle Tool Material · Insufficient wear resistance · Select a substrate with more wear resistance · Use a coated tool Cutting Edge Failure Chipping Cutting Conditions · Feed rate is too fast · Decrease cutting speed. · Cutting depth is too deep · Reduce depth of cut · Tool overhang is too long · Adjust tool overhang for correct length Machine Area · Work clamps are weak · Clamp the work piece firmly · Tool is not firmly attached · Make sure the tool is seated in the chuck properly Tool Fracture Cutting Conditions · Feed rate is too fast · Decrease cutting speed. · Cutting depth is too deep · Reduce depth of cut · Tool overhang is too long · Reduce tool overhang as much as possible · Cutting edge is too long · Select a tool with a shorter cutting edge Tool Shape · Web thickness is too small · Change to more appropriate web thickness Shoulder Deflection Cutting Conditions · Feed rate is too fast · Decrease cutting speed. · Cutting depth is too deep · Reduce depth of cut · Tool overhang is too long · Adjust tool overhang for correct length · Cutting on the down-cut · Change directions to up-cut Tool Shape · Helix angle is large · Use a tool with a smaller helix angle · Web thickness is too thin · Use a tool with the appropriate web thickness Unsatisfactory Cutting Conditions · Feed rate is too fast · Decrease cutting speed. Machined Surface Finish · Packing of chips · Use air blow · Use an insert with a larger relief pocket. Others Chattering Cutting Conditions · Cutting speed is too fast · Decrease the cutting speed · Cutting on the up-cut · Change directions to down-cut · Tool overhang is too long · Adjust tool overhang for correct length Tool Shape · Rake angle is large · Use a tool with an appropriate rake angle Machine Area · Work clamps are weak · Clamp the work piece firmly · Tool is not firmly attached · Make sure the tool is seated in the chuck properly Packing of Chips Cutting Conditions · Feed rate is too fast · Decrease cutting speed. · Cutting depth is too deep · Reduce depth of cut N Tool Shape · Too many teeth · Reduce number of teeth · Packing of chips · Use air blow Technical Guidance / References N21