Техническая информация Sumitomo - страница 18

Навигация

Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Каталог Sumitomo твердосплавные пластины

Каталог Sumitomo твердосплавные пластины Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

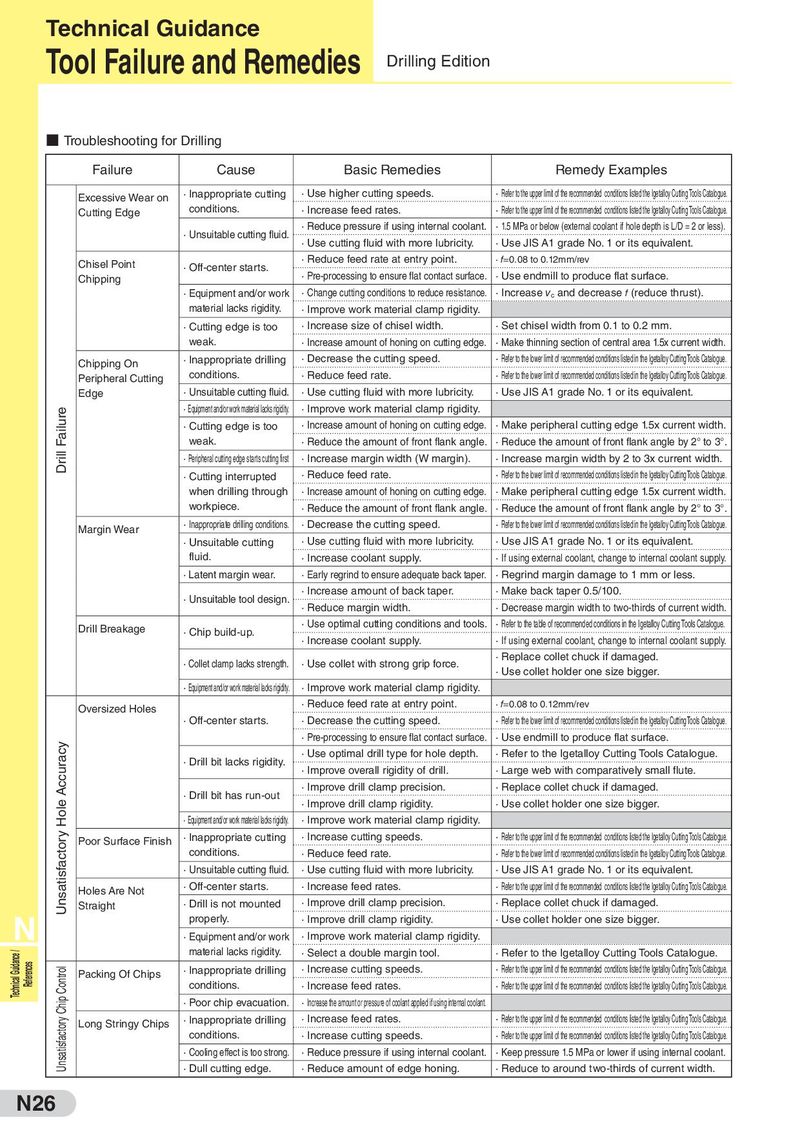

Technical Guidance Tool Failure and Remedies Drilling Edition ■ Troubleshooting for Drilling Failure Cause Basic Remedies Remedy Examples Excessive Wear on · Inappropriate cutting · Use higher cutting speeds. · Refer to the upper limit of the recommended conditions listed the Igetalloy Cutting Tools Catalogue. Cutting Edge conditions. · Increase feed rates. · Refer to the upper limit of the recommended conditions listed the Igetalloy Cutting Tools Catalogue. · Unsuitable cutting fluid. · Reduce pressure if using internal coolant. · 1.5 MPa or below (external coolant if hole depth is L/D = 2 or less). · Use cutting fluid with more lubricity. · Use JIS A1 grade No. 1 or its equivalent. Chisel Point · Off-center starts. · Reduce feed rate at entry point. · f=0.08 to 0.12mm/rev Chipping · Pre-processing to ensure flat contact surface. · Use endmill to produce flat surface. · Equipment and/or work · Change cutting conditions to reduce resistance. · Increase vc and decrease f (reduce thrust). material lacks rigidity. · Improve work material clamp rigidity. · Cutting edge is too · Increase size of chisel width. · Set chisel width from 0.1 to 0.2 mm. weak. · Increase amount of honing on cutting edge. · Make thinning section of central area 1.5x current width. Chipping On · Inappropriate drilling · Decrease the cutting speed. · Refer to the lower limit of recommended conditions listed in the Igetalloy Cutting Tools Catalogue. Peripheral Cutting conditions. · Reduce feed rate. · Refer to the lower limit of recommended conditions listed in the Igetalloy Cutting Tools Catalogue. Edge · Unsuitable cutting fluid. · Use cutting fluid with more lubricity. · Use JIS A1 grade No. 1 or its equivalent. Drill Failure · Equipment and/or work material lacks rigidity. · Improve work material clamp rigidity. · Cutting edge is too · Increase amount of honing on cutting edge. · Make peripheral cutting edge 1.5x current width. weak. · Reduce the amount of front flank angle. · Reduce the amount of front flank angle by 2° to 3°. · Peripheral cutting edge starts cutting first · Increase margin width (W margin). · Increase margin width by 2 to 3x current width. · Cutting interrupted · Reduce feed rate. · Refer to the lower limit of recommended conditions listed in the Igetalloy Cutting Tools Catalogue. when drilling through · Increase amount of honing on cutting edge. · Make peripheral cutting edge 1.5x current width. workpiece. · Reduce the amount of front flank angle. · Reduce the amount of front flank angle by 2° to 3°. Margin Wear · Inappropriate drilling conditions. · Decrease the cutting speed. · Refer to the lower limit of recommended conditions listed in the Igetalloy Cutting Tools Catalogue. · Unsuitable cutting · Use cutting fluid with more lubricity. · Use JIS A1 grade No. 1 or its equivalent. fluid. · Increase coolant supply. · If using external coolant, change to internal coolant supply. · Latent margin wear. · Early regrind to ensure adequate back taper. · Regrind margin damage to 1 mm or less. · Unsuitable tool design. · Increase amount of back taper. · Make back taper 0.5/100. · Reduce margin width. · Decrease margin width to two-thirds of current width. Drill Breakage · Chip build-up. · Use optimal cutting conditions and tools. · Refer to the table of recommended conditions in the Igetalloy Cutting Tools Catalogue. · Increase coolant supply. · If using external coolant, change to internal coolant supply. · Collet clamp lacks strength. · Use collet with strong grip force. · Replace collet chuck if damaged. · Use collet holder one size bigger. · Equipment and/or work material lacks rigidity. · Improve work material clamp rigidity. Oversized Holes · Reduce feed rate at entry point. · f=0.08 to 0.12mm/rev · Off-center starts. · Decrease the cutting speed. · Refer to the lower limit of recommended conditions listed in the Igetalloy Cutting Tools Catalogue. Unsatisfactory Hole Accuracy · Pre-processing to ensure flat contact surface. · Use endmill to produce flat surface. · Drill bit lacks rigidity. · Use optimal drill type for hole depth. · Refer to the Igetalloy Cutting Tools Catalogue. · Improve overall rigidity of drill. · Large web with comparatively small flute. · Drill bit has run-out · Improve drill clamp precision. · Replace collet chuck if damaged. · Improve drill clamp rigidity. · Use collet holder one size bigger. · Equipment and/or work material lacks rigidity. · Improve work material clamp rigidity. Poor Surface Finish · Inappropriate cutting · Increase cutting speeds. · Refer to the upper limit of the recommended conditions listed the Igetalloy Cutting Tools Catalogue. conditions. · Reduce feed rate. · Refer to the lower limit of recommended conditions listed in the Igetalloy Cutting Tools Catalogue. · Unsuitable cutting fluid. · Use cutting fluid with more lubricity. · Use JIS A1 grade No. 1 or its equivalent. Holes Are Not · Off-center starts. · Increase feed rates. · Refer to the upper limit of the recommended conditions listed the Igetalloy Cutting Tools Catalogue. Straight · Drill is not mounted · Improve drill clamp precision. · Replace collet chuck if damaged. N properly. · Improve drill clamp rigidity. · Use collet holder one size bigger. · Equipment and/or work · Improve work material clamp rigidity. Technical Guidance / material lacks rigidity. · Select a double margin tool. · Refer to the Igetalloy Cutting Tools Catalogue. References Unsatisfactory Chip Control Packing Of Chips · Inappropriate drilling · Increase cutting speeds. · Refer to the upper limit of the recommended conditions listed the Igetalloy Cutting Tools Catalogue. conditions. · Increase feed rates. · Refer to the upper limit of the recommended conditions listed the Igetalloy Cutting Tools Catalogue. · Poor chip evacuation. · Increase the amount or pressure of coolant applied if using internal coolant. Long Stringy Chips · Inappropriate drilling · Increase feed rates. · Refer to the upper limit of the recommended conditions listed the Igetalloy Cutting Tools Catalogue. conditions. · Increase cutting speeds. · Refer to the upper limit of the recommended conditions listed the Igetalloy Cutting Tools Catalogue. · Cooling effect is too strong. · Reduce pressure if using internal coolant. · Keep pressure 1.5 MPa or lower if using internal coolant. · Dull cutting edge. · Reduce amount of edge honing. · Reduce to around two-thirds of current width. N26