Техническая информация Sumitomo - страница 27

Навигация

Каталог Sumitomo пластины с алмазными вставками Sumidia

Каталог Sumitomo пластины с алмазными вставками Sumidia Общий каталог Sumitomo 2019 - 2020

Общий каталог Sumitomo 2019 - 2020 Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Каталог Sumitomo твердосплавные пластины

Каталог Sumitomo твердосплавные пластины Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

Каталог Sumitomo пластины с режущей кромкой-моноалмаз Sumicristal

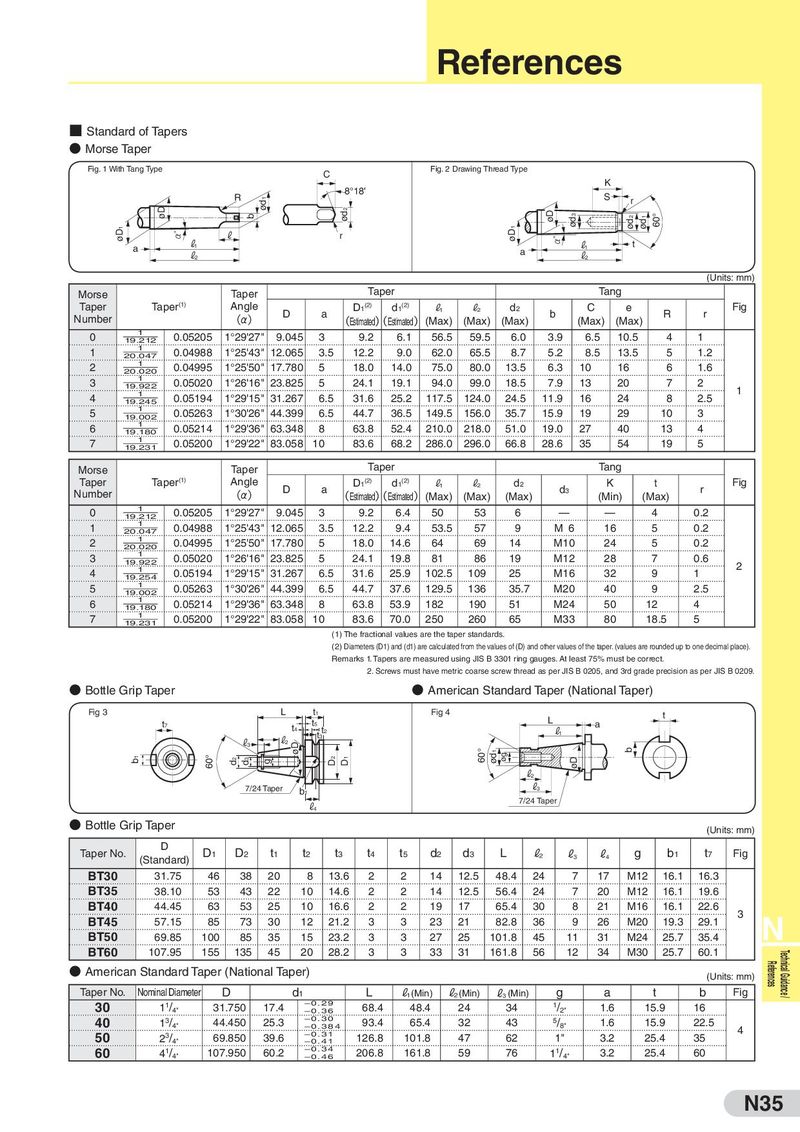

References ■ Standard of Tapers ● Morse Taper Fig. 1 With Tang Type C Fig. 2 Drawing Thread Type K R 8°18' S ød1 r øD b ød2 øD ød3 ød2 ød1 60° øD1 E L r øD1 E a N N t B a B (Units: mm) Morse Taper Taper Tang Taper Taper(1) Angle D a D1(2) d1(2) N B d2 b C e R r Fig Number (Estimated)(Estimated) (Max) (Max) (Max) (Max) (Max) 0 1 0.05205 1°29'27" 9.045 3 9.2 6.1 56.5 59.5 6.0 3.9 6.5 10.5 4 1 19.212 1 1 0.04988 1°25'43" 12.065 3.5 12.2 9.0 62.0 65.5 8.7 5.2 8.5 13.5 5 1.2 20.047 2 1 0.04995 1°25'50" 17.780 5 18.0 14.0 75.0 80.0 13.5 6.3 10 16 6 1.6 20.020 3 1 0.05020 1°26'16" 23.825 5 24.1 19.1 94.0 99.0 18.5 7.9 13 20 7 2 19.922 1 4 1 0.05194 1°29'15" 31.267 6.5 31.6 25.2 117.5 124.0 24.5 11.9 16 24 8 2.5 19.245 5 1 0.05263 1°30'26" 44.399 6.5 44.7 36.5 149.5 156.0 35.7 15.9 19 29 10 3 19.002 6 1 0.05214 1°29'36" 63.348 8 63.8 52.4 210.0 218.0 51.0 19.0 27 40 13 4 19.180 7 1 0.05200 1°29'22" 83.058 10 83.6 68.2 286.0 296.0 66.8 28.6 35 54 19 5 19.231 Morse Taper Taper Tang Taper Taper(1) Angle D a D1(2) d1(2) N B d2 d3 K t r Fig Number (Estimated)(Estimated) (Max) (Max) (Max) (Min) (Max) 0 1 0.05205 1°29'27" 9.045 3 9.2 6.4 50 53 6 — — 4 0.2 19.212 1 1 0.04988 1°25'43" 12.065 3.5 12.2 9.4 53.5 57 9 M6 16 5 0.2 20.047 2 1 0.04995 1°25'50" 17.780 5 18.0 14.6 64 69 14 M10 24 5 0.2 20.020 3 1 0.05020 1°26'16" 23.825 5 24.1 19.8 81 86 19 M12 28 7 0.6 19.922 2 4 1 0.05194 1°29'15" 31.267 6.5 31.6 25.9 102.5 109 25 M16 32 9 1 19.254 5 1 0.05263 1°30'26" 44.399 6.5 44.7 37.6 129.5 136 35.7 M20 40 9 2.5 19.002 6 1 0.05214 1°29'36" 63.348 8 63.8 53.9 182 190 51 M24 50 12 4 19.180 7 1 0.05200 1°29'22" 83.058 10 83.6 70.0 250 260 65 M33 80 18.5 5 19.231 (1) The fractional values are the taper standards. (2) Diameters (D1) and (d1) are calculated from the values of (D) and other values of the taper. (values are rounded up to one decimal place). Remarks 1. Tapers are measured using JIS B 3301 ring gauges. At least 75% must be correct. 2. Screws must have metric coarse screw thread as per JIS B 0205, and 3rd grade precision as per JIS B 0209. ● Bottle Grip Taper ● American Standard Taper (National Taper) Fig 3 L t1 Fig 4 t t7 t4 t5 L a t3t2 N L3 B øD 60° ød1 b b1 60° d2 d3 g D2 D1 øg øD B 7/24 Taper b1 L3 L4 7/24 Taper ● Bottle Grip Taper (Units: mm) Taper No. D D1 D2 t1 t2 t3 t4 t5 d2 d3 L B L3 L4 g b1 t7 Fig (Standard) BT30 31.75 46 38 20 8 13.6 2 2 14 12.5 48.4 24 7 17 M12 16.1 16.3 BT35 38.10 53 43 22 10 14.6 2 2 14 12.5 56.4 24 7 20 M12 16.1 19.6 BT40 44.45 63 53 25 10 16.6 2 2 19 17 65.4 30 8 21 M16 16.1 22.6 3 BT45 57.15 85 73 30 12 21.2 3 3 23 21 82.8 36 9 26 M20 19.3 29.1 N BT50 69.85 100 85 35 15 23.2 3 3 27 25 101.8 45 11 31 M24 25.7 35.4 BT60 107.95 155 135 45 20 28.2 3 3 33 31 161.8 56 12 34 M30 25.7 60.1 Technical Guidance / ● American Standard Taper (National Taper) (Units: mm) References Taper No. Nominal Diameter D d1 L N (Min) B (Min) L3 (Min) g a t b Fig 30 11/4" 31.750 17.4 –0.29 68.4 48.4 24 34 1/2" 1.6 15.9 16 –0.36 40 13/4" 44.450 25.3 –0.30 93.4 65.4 32 43 5/8" 1.6 15.9 22.5 –0.384 4 50 23/4" 69.850 39.6 –0.31 126.8 101.8 47 62 1" 3.2 25.4 35 –0.41 60 41/4" 107.950 60.2 –0.34 206.8 161.8 59 76 11/4" 3.2 25.4 60 –0.46 N35