Каталог Sumitomo сплавы и режимы - страница 9

Навигация

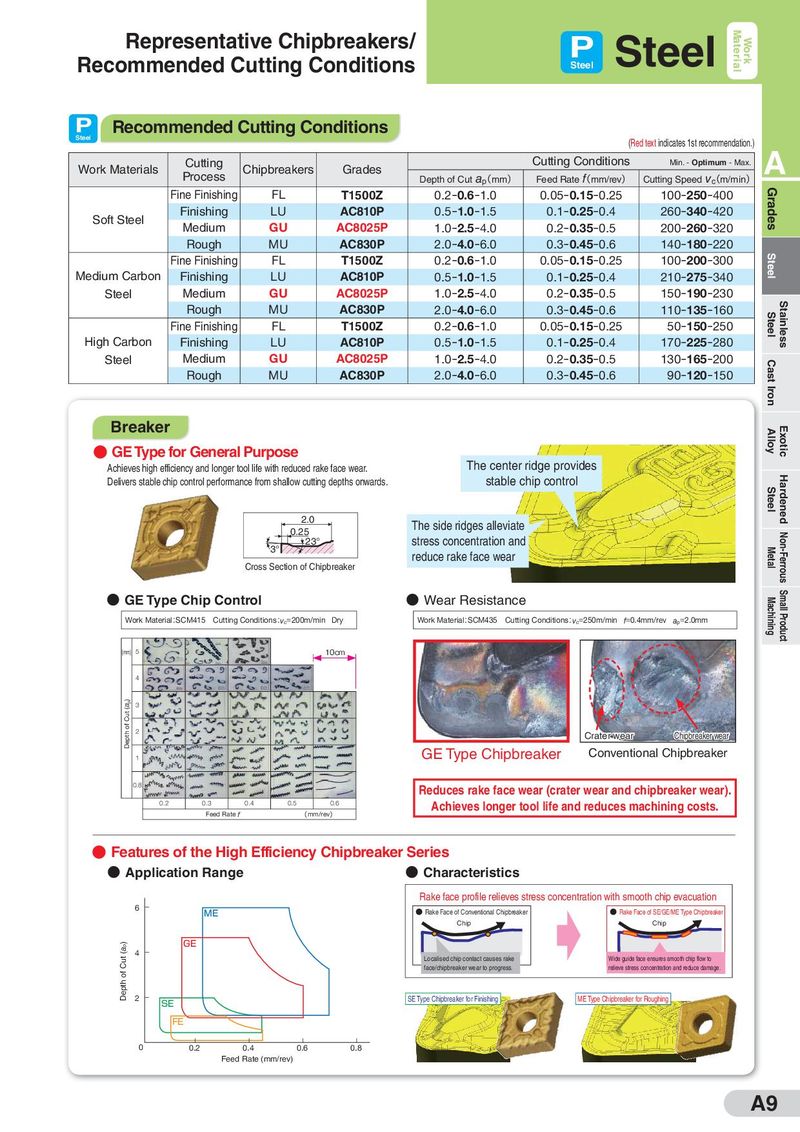

Representative Chipbreakers/ P Steel Ma t e r i a l Wo r k Recommended Cutting Conditions Steel P Recommended Cutting Conditions Steel (Red text indicates 1st recommendation.) Work Materials Cutting Chipbreakers Grades Cutting Conditions Min. - Optimum - Max. A Process Depth of Cut a(p mm) Feed Rate (f mm/rev) Cutting Speed v(c m/min) Fine Finishing FL T1500Z 0.2-0.6-1.0 0.05-0.15-0.25 100-250-400 Grades Soft Steel Finishing LU AC810P 0.5-1.0-1.5 0.1-0.25-0.4 260-340-420 Medium GU AC8025P 1.0-2.5-4.0 0.2-0.35-0.5 200-260-320 Rough MU AC830P 2.0-4.0-6.0 0.3-0.45-0.6 140-180-220 Fine Finishing FL T1500Z 0.2-0.6-1.0 0.05-0.15-0.25 100-200-300 Steel Medium Carbon Finishing LU AC810P 0.5-1.0-1.5 0.1-0.25-0.4 210-275-340 Steel Medium GU AC8025P 1.0-2.5-4.0 0.2-0.35-0.5 150-190-230 Rough MU AC830P 2.0-4.0-6.0 0.3-0.45-0.6 110-135-160 Steel Stainless Fine Finishing FL T1500Z 0.2-0.6-1.0 0.05-0.15-0.25 50-150-250 High Carbon Finishing LU AC810P 0.5-1.0-1.5 0.1-0.25-0.4 170-225-280 Steel Medium GU AC8025P 1.0-2.5-4.0 0.2-0.35-0.5 130-165-200 Cast Iron Rough MU AC830P 2.0-4.0-6.0 0.3-0.45-0.6 90-120-150 Breaker Alloy Exotic ● GE Type for General Purpose Achieves high efficiency and longer tool life with reduced rake face wear. The center ridge provides Delivers stable chip control performance from shallow cutting depths onwards. stable chip control Steel Hardened 2.0 The side ridges alleviate 0.25 stress concentration and Non-Ferrous 3° 23° Cross Section of Chipbreaker reduce rake face wear Metal ● GE Type Chip Control ● Wear Resistance Machining Small Product Work Materia:l SCM415 Cutting Conditions:vc=200m/min Dry Work Materia:l SCM435 Cutting Conditions:vc=250m/min f=0.4mm/rev ap=2.0mm (mm) 5 10cm 4 p) 3 Depth of Cut ( 2 Crater wear Chipbreaker wear 1 GE Type Chipbreaker Conventional Chipbreaker 0.8 Reduces rake face wear (crater wear and chipbreaker wear). 0.2 0.3 0.4 0.5 0.6 Achieves longer tool life and reduces machining costs. Feed Rate (mm/rev) ● Features of the High Efficiency Chipbreaker Series ● Application Range ● Characteristics Rake face profile relieves stress concentration with smooth chip evacuation 6 ME ● Rake Face of Conventional Chipbreaker ● Rake Face of SE/GE/ME Type Chipbreaker Chip Chip Depth of Cut (ap) GE 4 Localised chip contact causes rake Wide guide face ensures smooth chip flow to face/chipbreaker wear to progress. relieve stress concentration and reduce damage. 2 SE SE Type Chipbreaker for Finishing ME Type Chipbreaker for Roughing FE 0 0.2 0.4 0.6 0.8 Feed Rate (mm/rev) A9

Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Каталог Sumitomo сверла и развертки

Каталог Sumitomo сверла и развертки Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами