Каталог Sumitomo сплавы и режимы - страница 25

Навигация

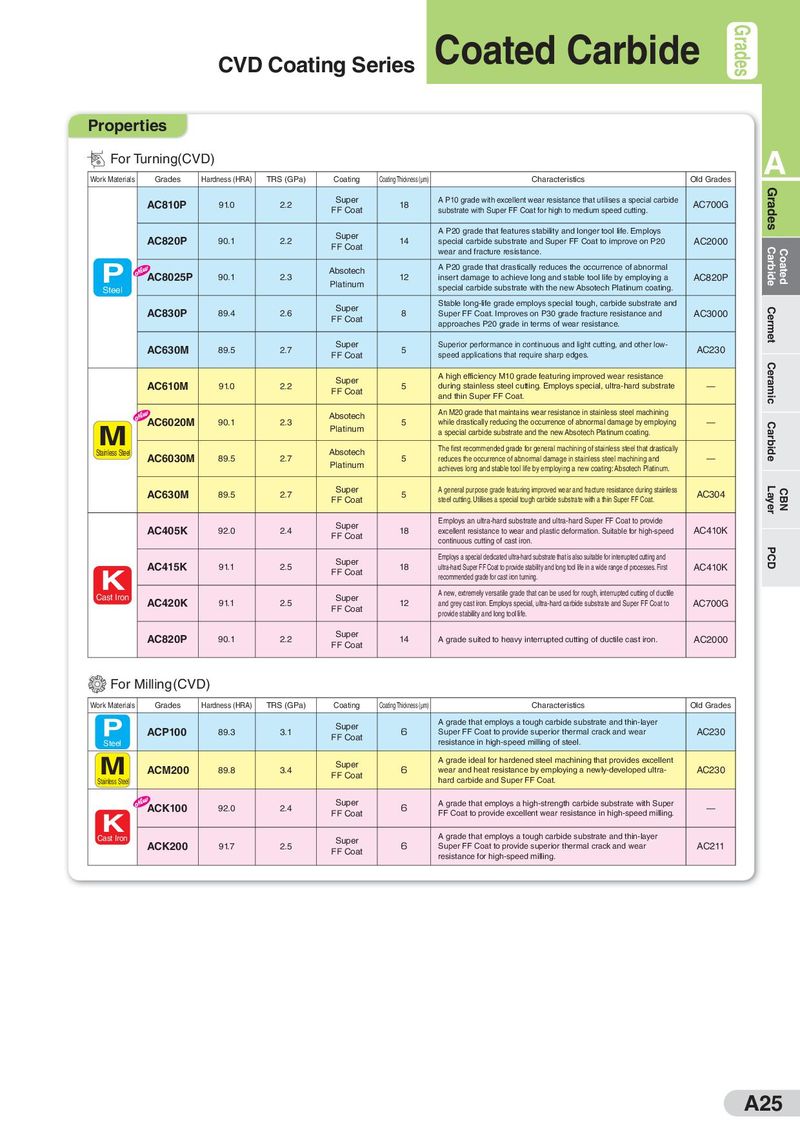

CVD Coating Series Coated Carbide Grades Properties For Turning(CVD) A Work Materials Grades Hardness (HRA) TRS (GPa) Coating Coating Thickness (μm) Characteristics Old Grades AC810P 91.0 2.2 Super 18 A P10 grade with excellent wear resistance that utilises a special carbide AC700G Grades FF Coat substrate with Super FF Coat for high to medium speed cutting. Super A P20 grade that features stability and longer tool life. Employs AC820P 90.1 2.2 FF Coat 14 special carbide substrate and Super FF Coat to improve on P20 AC2000 wear and fracture resistance. Carbide Coated P Absotech A P20 grade that drastically reduces the occurrence of abnormal AC8025P 90.1 2.3 Platinum 12 insert damage to achieve long and stable tool life by employing a AC820P Steel special carbide substrate with the new Absotech Platinum coating. Super Stable long-life grade employs special tough, carbide substrate and Cermet AC830P 89.4 2.6 FF Coat 8 Super FF Coat. Improves on P30 grade fracture resistance and AC3000 approaches P20 grade in terms of wear resistance. AC630M 89.5 2.7 Super 5 Superior performance in continuous and light cutting, and other low- AC230 FF Coat speed applications that require sharp edges. Super A high efficiency M10 grade featuring improved wear resistance Ceramic AC610M 91.0 2.2 FF Coat 5 during stainless steel cutting. Employs special, ultra-hard substrate — and thin Super FF Coat. Absotech An M20 grade that maintains wear resistance in stainless steel machining M AC6020M 90.1 2.3 Platinum 5 while drastically reducing the occurrence of abnormal damage by employing — Carbide a special carbide substrate and the new Absotech Platinum coating. Stainless Steel Absotech The first recommended grade for general machining of stainless steel that drastically AC6030M 89.5 2.7 Platinum 5 reduces the occurrence of abnormal damage in stainless steel machining and — achieves long and stable tool life by employing a new coating: Absotech Platinum. AC630M 89.5 2.7 Super 5 A general purpose grade featuring improved wear and fracture resistance during stainless AC304 Layer CBN FF Coat steel cutting. Utilises a special tough carbide substrate with a thin Super FF Coat. Super Employs an ultra-hard substrate and ultra-hard Super FF Coat to provide AC405K 92.0 2.4 FF Coat 18 excellent resistance to wear and plastic deformation. Suitable for high-speed AC410K continuous cutting of cast iron. Super Employs a special dedicated ultra-hard substrate that is also suitable for interrupted cutting and PCD K AC415K 91.1 2.5 FF Coat 18 ultra-hard Super FF Coat to provide stability and long tool life in a wide range of processes. First AC410K recommended grade for cast iron turning. Cast Iron Super A new, extremely versatile grade that can be used for rough, interrupted cutting of ductile AC420K 91.1 2.5 FF Coat 12 and grey cast iron. Employs special, ultra-hard carbide substrate and Super FF Coat to AC700G provide stability and long tool life. AC820P 90.1 2.2 Super 14 A grade suited to heavy interrupted cutting of ductile cast iron. AC2000 FF Coat For Milling(CVD) Work Materials Grades Hardness (HRA) TRS (GPa) Coating Coating Thickness (μm) Characteristics Old Grades P Super A grade that employs a tough carbide substrate and thin-layer ACP100 89.3 3.1 FF Coat 6 Super FF Coat to provide superior thermal crack and wear AC230 Steel resistance in high-speed milling of steel. M Super A grade ideal for hardened steel machining that provides excellent ACM200 89.8 3.4 FF Coat 6 wear and heat resistance by employing a newly-developed ultra- AC230 Stainless Steel hard carbide and Super FF Coat. ACK100 92.0 2.4 Super 6 A grade that employs a high-strength carbide substrate with Super — K FF Coat FF Coat to provide excellent wear resistance in high-speed milling. Cast Iron Super A grade that employs a tough carbide substrate and thin-layer ACK200 91.7 2.5 FF Coat 6 Super FF Coat to provide superior thermal crack and wear AC211 resistance for high-speed milling. A25

Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Каталог Sumitomo сверла и развертки

Каталог Sumitomo сверла и развертки Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами