Каталог Sumitomo сплавы и режимы - страница 11

Навигация

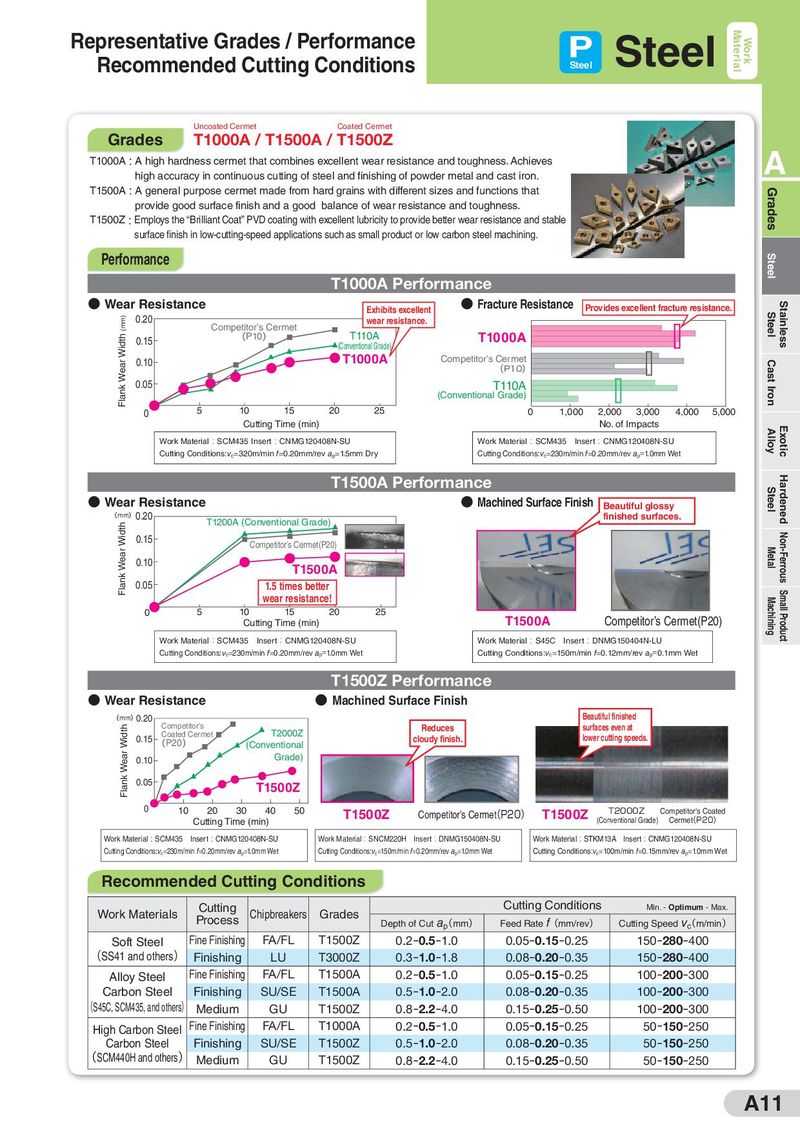

Representative Grades / Performance P Steel Ma t e r i a l Wo r k Recommended Cutting Conditions Steel Uncoated Cermet Coated Cermet Grades T1000A / T1500A / T1500Z T1000A:A high hardness cermet that combines excellent wear resistance and toughness. Achieves A high accuracy in continuous cutting of steel and finishing of powder metal and cast iron. T1500A:A general purpose cermet made from hard grains with different sizes and functions that Grades provide good surface finish and a good balance of wear resistance and toughness. T1500Z:Employs the “Brilliant Coat” PVD coating with excellent lubricity to provide better wear resistance and stable surface finish in low-cutting-speed applications such as small product or low carbon steel machining. Performance Steel T1000A Performance ● Wear Resistance Exhibits excellent ● Fracture Resistance Provides excellent fracture resistance. Stainless Flank Wear Width (mm) 0.20 Competitor’s Cermet wear resistance. Steel 0.15 (P10) T110A T1000A (Conventional Grade) 0.10 T1000A Competitor’s Cermet Cast Iron (P10) 0.05 T110A (Conventional Grade) 0 5 10 15 20 25 0 1,000 2,000 3,000 4,000 5,000 Cutting Time (min) No. of Impacts Alloy Exotic Work Material:SCM435 Insert:CNMG120408N-SU Work Material:SCM435 Insert:CNMG120408N-SU Cutting Conditions:vc=320m/min f=0.20mm/rev ap=1.5mm Dry Cutting Conditions:vc=230m/min f=0.20mm/rev ap=1.0mm Wet T1500A Performance Steel Hardened ● Wear Resistance ● Machined Surface Finish Beautiful glossy (mm)0.20 T1200A (Conventional Grade) finished surfaces. Flank Wear Width 0.15 Competitor’s Cermet(P20) Non-Ferrous 0.10 T1500A Metal 0.05 1.5 times better Small Product wear resistance! Machining 0 5 10 15 20 25 T1500A Competitor’s Cermet(P20) Cutting Time (min) Work Material:SCM435 Insert:CNMG120408N-SU Work Material:S45C Insert:DNMG150404N-LU Cutting Conditions:vc=230m/min f=0.20mm/rev ap=1.0mm Wet Cutting Conditions:vc=150m/min f=0.12mm/rev ap=0.1mm Wet T1500Z Performance ● Wear Resistance ● Machined Surface Finish (mm)0.20 Beautiful finished Flank Wear Width Competitor's T2000Z Reduces surfaces even at 0.15 Coated Cermet cloudy finish. lower cutting speeds. (P20) (Conventional 0.10 Grade) 0.05 T1500Z 0 10 20 30 40 50 T1500Z Competitor’s Cerme(t P20) T1500Z T2000Z Competitor's Coated Cutting Time (min) (Conventional Grade) Cerme(t P20) Work Material:SCM435 Insert:CNMG120408N-SU Work Material:SNCM220H Insert:DNMG150408N-SU Work Material:STKM13A Insert:CNMG120408N-SU Cutting Conditions:vc=230m/min f=0.20mm/rev ap=1.0mm Wet Cutting Conditions:vc=150m/min f=0.20mm/rev ap=1.0mm Wet Cutting Conditions:vc=100m/min f=0.15mm/rev ap=1.0mm Wet Recommended Cutting Conditions Work Materials Cutting Chipbreakers Grades Cutting Conditions Min. - Optimum - Max. Process Depth of Cut a(p mm) Feed Rate f(mm/rev) Cutting Speed v(c m/min) Soft Steel Fine Finishing FA/FL T1500Z 0.2-0.5-1.0 0.05-0.15-0.25 150-280-400 (SS41 and others) Finishing LU T3000Z 0.3-1.0-1.8 0.08-0.20-0.35 150-280-400 Alloy Steel Fine Finishing FA/FL T1500A 0.2-0.5-1.0 0.05-0.15-0.25 100-200-300 Carbon Steel Finishing SU/SE T1500A 0.5-1.0-2.0 0.08-0.20-0.35 100-200-300 (S45C, SCM435, and others) Medium GU T1500Z 0.8-2.2-4.0 0.15-0.25-0.50 100-200-300 High Carbon Steel Fine Finishing FA/FL T1000A 0.2-0.5-1.0 0.05-0.15-0.25 50-150-250 Carbon Steel Finishing SU/SE T1500Z 0.5-1.0-2.0 0.08-0.20-0.35 50-150-250 (SCM440H and others) Medium GU T1500Z 0.8-2.2-4.0 0.15-0.25-0.50 50-150-250 A11

Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Каталог Sumitomo сверла и развертки

Каталог Sumitomo сверла и развертки Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами