Каталог Sumitomo сплавы и режимы - страница 32

Навигация

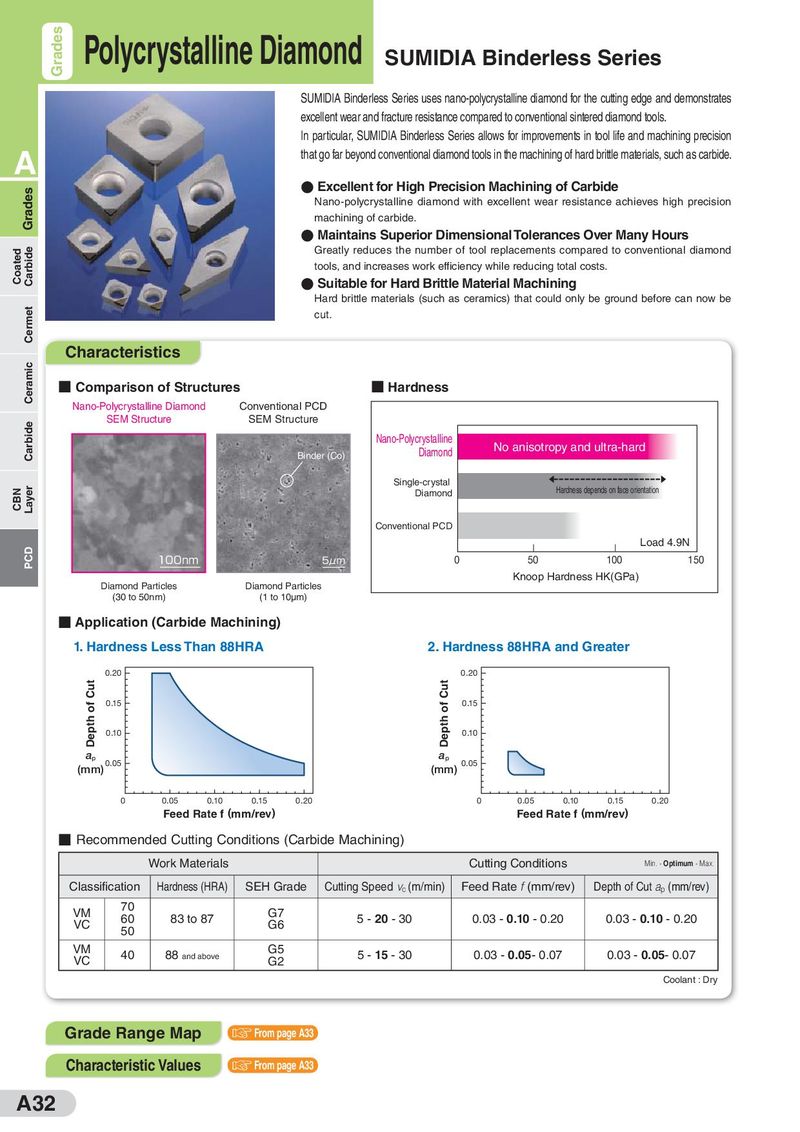

Grades Polycrystalline Diamond SUMIDIA Binderless Series SUMIDIA Binderless Series uses nano-polycrystalline diamond for the cutting edge and demonstrates excellent wear and fracture resistance compared to conventional sintered diamond tools. In particular, SUMIDIA Binderless Series allows for improvements in tool life and machining precision A that go far beyond conventional diamond tools in the machining of hard brittle materials, such as carbide. Grades ● Excellent for High Precision Machining of Carbide Nano-polycrystalline diamond with excellent wear resistance achieves high precision machining of carbide. ● Maintains Superior Dimensional Tolerances Over Many Hours Coated Carbide Greatly reduces the number of tool replacements compared to conventional diamond tools, and increases work efficiency while reducing total costs. ● Suitable for Hard Brittle Material Machining Hard brittle materials (such as ceramics) that could only be ground before can now be Cermet cut. Characteristics Ceramic ■ Comparison of Structures ■ Hardness Nano-Polycrystalline Diamond Conventional PCD Carbide SEM Structure SEM Structure Nano-Polycrystalline No anisotropy and ultra-hard Binder (Co) Diamond Layer Single-crystal Hardness depends on face orientation CBN Diamond Conventional PCD PCD Load 4.9N 100nm 5μm 0 50 100 150 Diamond Particles Diamond Particles Knoop Hardness HK(GPa) (30 to 50nm) (1 to 10μm) ■ Application (Carbide Machining) 1. Hardness Less Than 88HRA 2. Hardness 88HRA and Greater 0.20 0.20 Cut Cut of 0.15 of 0.15 Depth 0.10 Depth 0.10 ap 0.05 ap 0.05 (mm) (mm) 0 0.05 0.10 0.15 0.20 0 0.05 0.10 0.15 0.20 Feed Rate f (mm/rev) Feed Rate f (mm/rev) ■ Recommended Cutting Conditions (Carbide Machining) Work Materials Cutting Conditions Min. - Optimum - Max. Classification Hardness (HRA) SEH Grade Cutting Speed vc (m/min) Feed Rate f (mm/rev) Depth of Cut ap (mm/rev) VM 70 G7 VC 60 83 to 87 G6 5 - 20 - 30 0.03 - 0.10 - 0.20 0.03 - 0.10 - 0.20 50 VM 40 88 and above G5 5 - 15 - 30 0.03 - 0.05- 0.07 0.03 - 0.05- 0.07 VC G2 Coolant : Dry Grade Range Map From page A33 Characteristic Values From page A33 A32

Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Каталог Sumitomo сверла и развертки

Каталог Sumitomo сверла и развертки Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами