Каталог Sumitomo сплавы и режимы - страница 19

Навигация

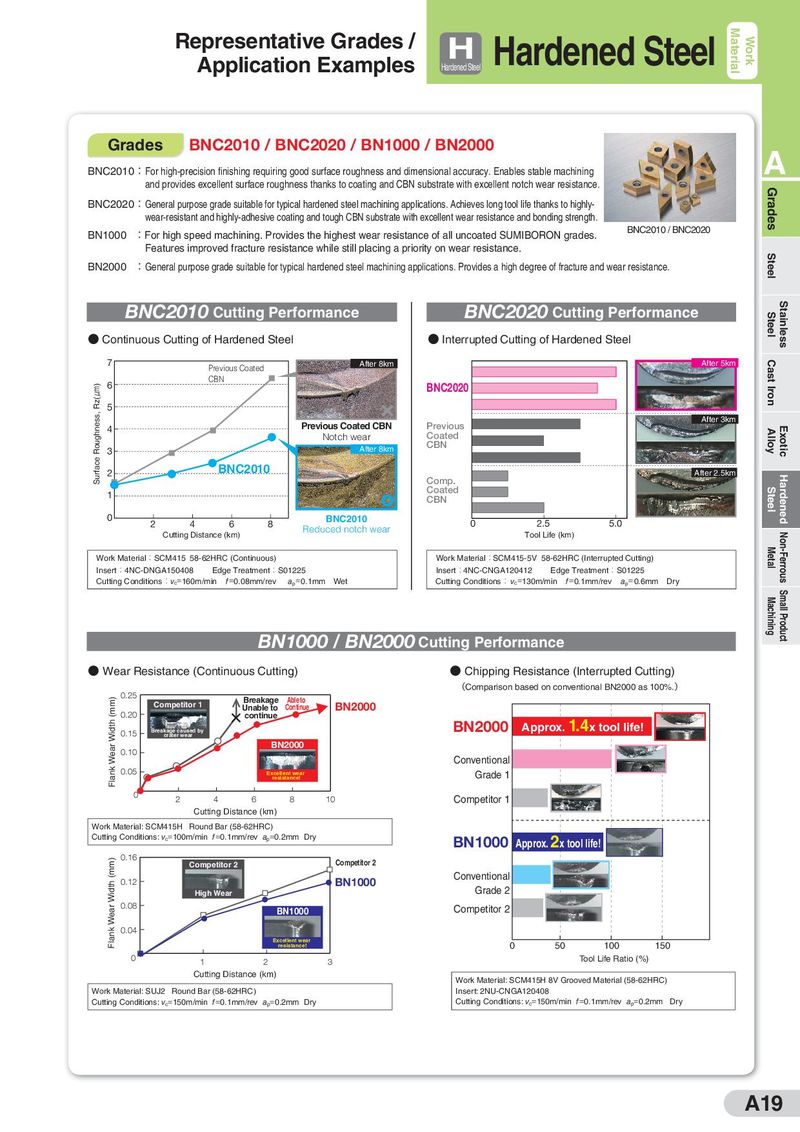

Representative Grades / H Hardened Steel Material Work Application Examples Hardened Steel Grades BNC2010 / BNC2020 / BN1000 / BN2000 A BNC2010:For high-precision finishing requiring good surface roughness and dimensional accuracy. Enables stable machining and provides excellent surface roughness thanks to coating and CBN substrate with excellent notch wear resistance. Grades BNC2020:General purpose grade suitable for typical hardened steel machining applications. Achieves long tool life thanks to highly- wear-resistant and highly-adhesive coating and tough CBN substrate with excellent wear resistance and bonding strength. BN1000 :For high speed machining. Provides the highest wear resistance of all uncoated SUMIBORON grades. BNC2010 / BNC2020 Features improved fracture resistance while still placing a priority on wear resistance. Steel BN2000 :General purpose grade suitable for typical hardened steel machining applications. Provides a high degree of fracture and wear resistance. BNC2010 Cutting Performance BNC2020 Cutting Performance Steel Stainless ● Continuous Cutting of Hardened Steel ● Interrupted Cutting of Hardened Steel 7 Previous Coated After 8km After 5km Cast Iron 6 CBN ■ Surface Roughness, Rz(μm) BNC2020 5 Previous Coated CBN Previous After 3km 4 ■ Notch wear Coated Alloy Exotic ● CBN 3 ■ After 8km 2 ● ●BNC2010 After 2.5km Hardened ●■ Comp. 1 Coated Steel CBN 0 2 4 6 8 BNC2010 0 2.5 5.0 Cutting Distance (km) Reduced notch wear Tool Life (km) Non-Ferrous Work Material:SCM415 58-62HRC (Continuous) Work Material:SCM415-5V 58-62HRC (Interrupted Cutting) Metal Insert:4NC-DNGA150408 Edge Treatment:S01225 Insert:4NC-CNGA120412 Edge Treatment:S01225 Cutting Conditions:vc=160m/min f =0.08mm/rev ap=0.1mm Wet Cutting Conditions: vc=130m/min f =0.1mm/rev ap=0.6mm Dry Machining Small Product BN1000 / BN2000 Cutting Performance ● Wear Resistance (Continuous Cutting) ● Chipping Resistance (Interrupted Cutting) (Comparison based on conventional BN2000 as 100%.) Flank Wear Width (mm) 0.25 Breakage Able to Competitor 1 Unable to Continue BN2000 0.20 continue 0.15 Breakage caused by BN2000 Approx. 1.4x tool life! crater wear BN2000 0.10 Conventional 0.05 Excellent wear Grade 1 resistance! 0 2 4 6 8 10 Competitor 1 Cutting Distance (km) Work Material: SCM415H Round Bar (58-62HRC) Cutting Conditions: vc=100m/min f =0.1mm/rev ap=0.2mm Dry BN1000 Approx. 2x tool life! Flank Wear Width (mm) 0.16 Competitor 2 Competitor 2 0.12 BN1000 Conventional High Wear Grade 2 0.08 BN1000 Competitor 2 0.04 Excellent wear 0 50 100 150 resistance! 0 1 2 3 Tool Life Ratio (%) Cutting Distance (km) Work Material: SCM415H 8V Grooved Material (58-62HRC) Work Material: SUJ2 Round Bar (58-62HRC) Insert: 2NU-CNGA120408 Cutting Conditions: vc=150m/min f =0.1mm/rev ap=0.2mm Dry Cutting Conditions: vc=150m/min f =0.1mm/rev ap=0.2mm Dry A19

Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Каталог Sumitomo сверла и развертки

Каталог Sumitomo сверла и развертки Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами