Каталог Sumitomo сплавы и режимы - страница 10

Навигация

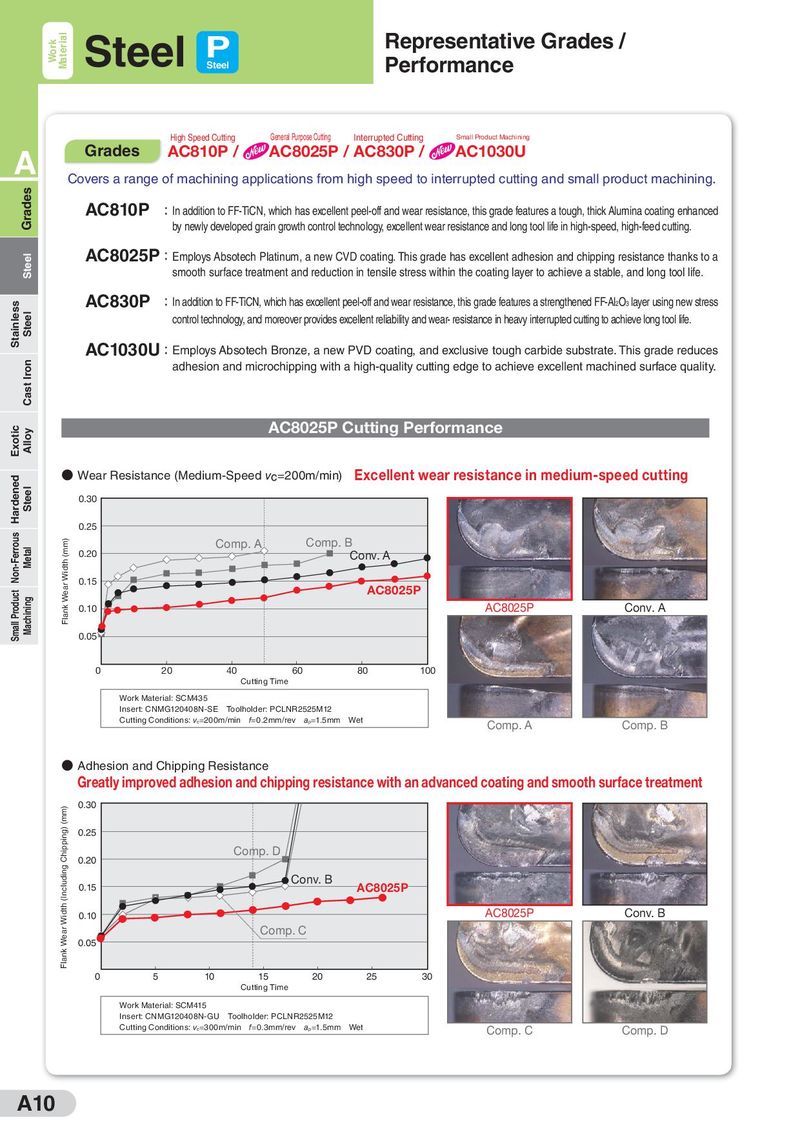

Work Material Steel P Representative Grades / Steel Performance High Speed Cutting General Purpose Cutting Interrupted Cutting Small Product Machining A Grades AC810P / AC8025P / AC830P / AC1030U Covers a range of machining applications from high speed to interrupted cutting and small product machining. Grades AC810P :In addition to FF-TiCN, which has excellent peel-off and wear resistance, this grade features a tough, thick Alumina coating enhanced by newly developed grain growth control technology, excellent wear resistance and long tool life in high-speed, high-feed cutting. Steel AC8025P:Employs Absotech Platinum, a new CVD coating. This grade has excellent adhesion and chipping resistance thanks to a smooth surface treatment and reduction in tensile stress within the coating layer to achieve a stable, and long tool life. Stainless AC830P :In addition to FF-TiCN, which has excellent peel-off and wear resistance, this grade features a strengthened FF-Al2O3 layer using new stress Steel control technology, and moreover provides excellent reliability and wear- resistance in heavy interrupted cutting to achieve long tool life. AC1030U:Employs Absotech Bronze, a new PVD coating, and exclusive tough carbide substrate. This grade reduces Cast Iron adhesion and microchipping with a high-quality cutting edge to achieve excellent machined surface quality. Exotic Alloy AC8025P Cutting Performance Hardened ● Wear Resistance (Medium-Speed vc=200m/min) Excellent wear resistance in medium-speed cutting Steel 0.30 0.25 Non-Ferrous Metal Flank Wear Width (mm) Comp. A ◆ Comp. B 0.20 ◆ ◆ ◆ ■ Conv. A ● ◆ ■ ■ ■ ● ● ◆ ■ ■ ■ ● ● ● ● ● 0.15 ◆ ● ● ● ● ● ● AC8025P Small Product ●■ ● ● Machining 0.10 ●■ ● ● ● AC8025P Conv. A ● ● ● 0.05 ●◆■● 0 20 40 60 80 100 Cutting Time Work Material: SCM435 Insert: CNMG120408N-SE Toolholder: PCLNR2525M12 Cutting Conditions: vc=200m/min f=0.2mm/rev ap=1.5mm Wet Comp. A Comp. B ● Adhesion and Chipping Resistance Greatly improved adhesion and chipping resistance with an advanced coating and smooth surface treatment Flank Wear Width (Including Chipping) (mm) 0.30 0.25 0.20 Comp. D ■ ■ ◆● Conv. B 0.15 ■●◆ ■●◆ ◆● AC8025P ■● ■●◆ ● ● ● ● 0.10 ●◆ ● ● ● ● AC8025P Conv. B 0.05●●■◆ Comp. C 0 5 10 15 20 25 30 Cutting Time Work Material: SCM415 Insert: CNMG120408N-GU Toolholder: PCLNR2525M12 Cutting Conditions: vc=300m/min f=0.3mm/rev ap=1.5mm Wet Comp. C Comp. D A10

Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Каталог Sumitomo сверла и развертки

Каталог Sumitomo сверла и развертки Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами