Каталог Sumitomo сплавы и режимы - страница 8

Навигация

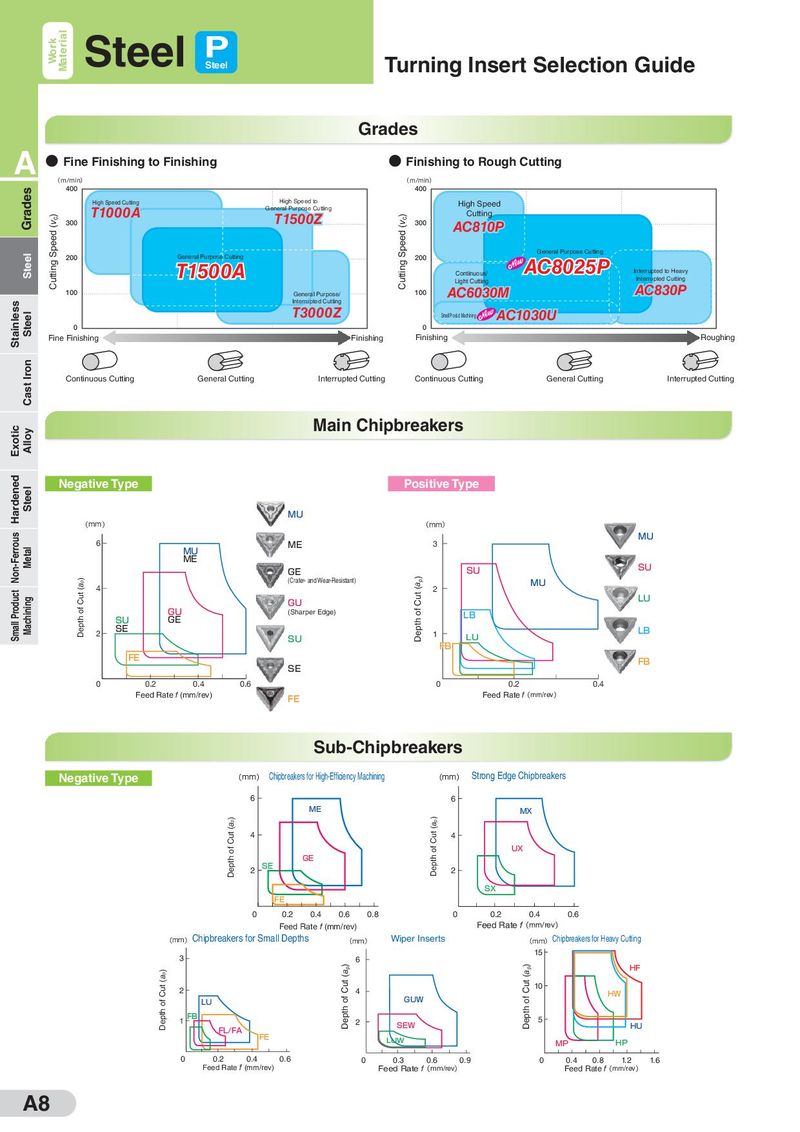

Work Material Steel P Turning Insert Selection Guide Steel Grades A ● Fine Finishing to Finishing ● Finishing to Rough Cutting (m/min) (m/min) Grades 400 400 High Speed Cutting High Speed to High Speed T1000A General Purpose Cutting Cutting Cutting Speed (vc) 300 T1500Z Cutting Speed (vc) 300 AC810P Steel General Purpose Cutting General Purpose Cutting 200 200 AC8025P T1500A Continuous/ Interrupted to Heavy Light Cutting Interrupted Cutting 100 General Purpose/ 100 AC6030M AC830P Stainless Interrupted Cutting Steel T3000Z Small Product Machining AC1030U 0 0 Fine Finishing Finishing Finishing Roughing Cast Iron Continuous Cutting General Cutting Interrupted Cutting Continuous Cutting General Cutting Interrupted Cutting Exotic Alloy Main Chipbreakers Hardened Steel Negative Type Positive Type MU (mm) (mm) Non-Ferrous 6 3 MU Metal MU ME ME GE SU SU Depth of Cut (ap) (Crater- and Wear-Resistant) Depth of Cut (ap) MU Small Product 4 2 Machining GU LU GU (Sharper Edge) LB SU GE 2 SE 1 LB SU LU FB FE FB SE 0 0.2 0.4 0.6 0 0.2 0.4 Feed Rate f (mm/rev) FE Feed Rate f(mm/rev) Sub-Chipbreakers Negative Type (mm) Chipbreakers for High-Efficiency Machining (mm) Strong Edge Chipbreakers 6 6 ME MX Depth of Cut (ap) 4 Depth of Cut (ap) 4 UX GE 2 SE 2 SX FE 0 0.2 0.4 0.6 0.8 0 0.2 0.4 0.6 Feed Rate f (mm/rev) Feed Rate f(mm/rev) (mm) Chipbreakers for Small Depths (mm) Wiper Inserts (mm) Chipbreakers for Heavy Cutting 3 15 (ap) 6 (ap) Depth of Cut (ap) HF 2 Cut 4 Cut 10 of GUW of HW LU Depth Depth 1 FB 2 5 FL/FA SEW HU FE LUW MP HP 0 0.2 0.4 0.6 0 0.3 0.6 0.9 0 0.4 0.8 1.2 1.6 Feed Rate f (mm/rev) Feed Rate f(mm/rev) Feed Rate f(mm/rev) A8

Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Каталог Sumitomo сверла и развертки

Каталог Sumitomo сверла и развертки Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами