Каталог Sumitomo сплавы и режимы - страница 23

Навигация

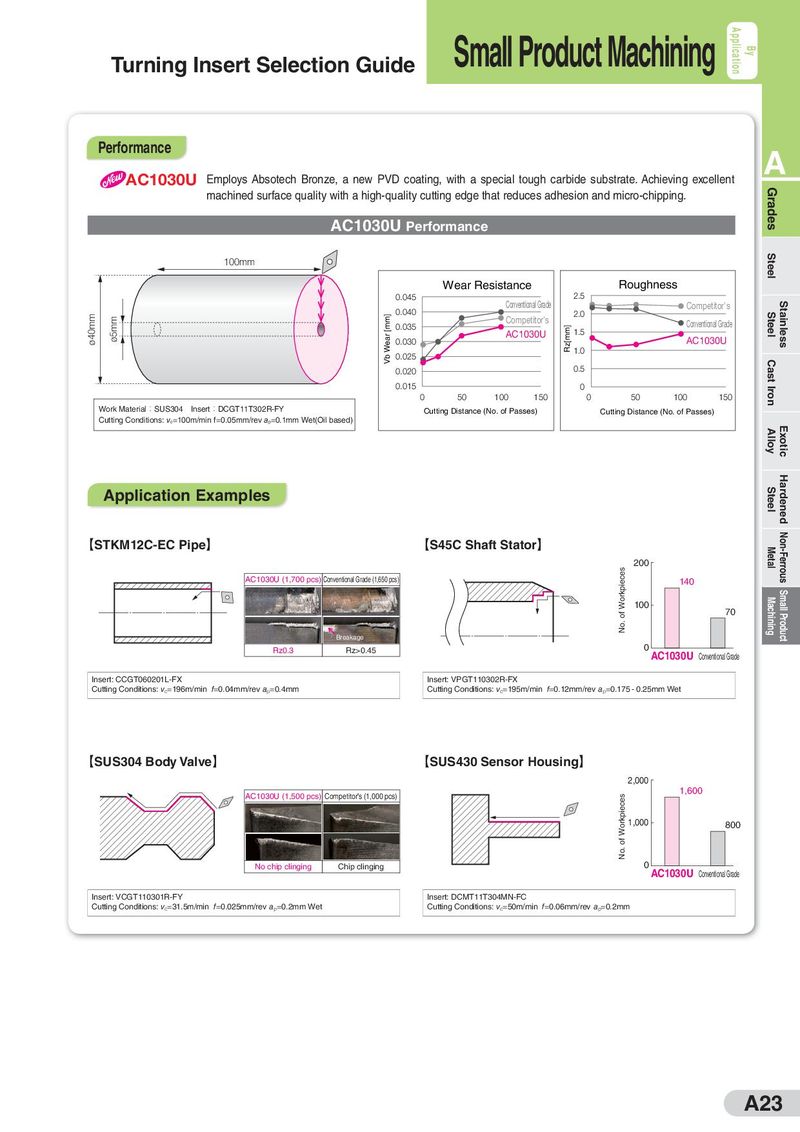

Small Product Machining Application By Turning Insert Selection Guide Performance A AC1030U Employs Absotech Bronze, a new PVD coating, with a special tough carbide substrate. Achieving excellent machined surface quality with a high-quality cutting edge that reduces adhesion and micro-chipping. Grades AC1030U Performance 100mm Steel Wear Resistance Roughness 0.045 2.5 0.040 Conventional Grade Competitor's Stainless ø40mm ø5mm Wear [mm] Competitor's 2.0 Steel 0.035 Rz[mm] Conventional Grade AC1030U 1.5 0.030 AC1030U Vb 0.025 1.0 0.020 0.5 Cast Iron 0.015 0 0 50 100 150 0 50 100 150 Work Material:SUS304 Insert:DCGT11T302R-FY Cutting Distance (No. of Passes) Cutting Distance (No. of Passes) Cutting Conditions: vc=100m/min f=0.05mm/rev ap=0.1mm Wet(Oil based) Alloy Exotic Application Examples Steel Hardened 【STKM12C-EC Pipe】 【S45C Shaft Stator】 Metal Non-Ferrous No. of Workpieces 200 AC1030U (1,700 pcs) Conventional Grade (1,650 pcs) 140 100 70 Machining Small Product Breakage Rz0.3 Rz>0.45 0 AC1030U Conventional Grade Insert: CCGT060201L-FX Insert: VPGT110302R-FX Cutting Conditions: vc=196m/min f=0.04mm/rev ap=0.4mm Cutting Conditions: vc=195m/min f=0.12mm/rev ap=0.175 - 0.25mm Wet 【SUS304 Body Valve】 【SUS430 Sensor Housing】 2,000 AC1030U (1,500 pcs) Competitor's (1,000 pcs) No. of Workpieces 1,600 1,000 800 No chip clinging Chip clinging 0 AC1030U Conventional Grade Insert: VCGT110301R-FY Insert: DCMT11T304MN-FC Cutting Conditions: vc=31.5m/min f=0.025mm/rev ap=0.2mm Wet Cutting Conditions: vc=50m/min f=0.06mm/rev ap=0.2mm A23

Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Каталог Sumitomo сверла и развертки

Каталог Sumitomo сверла и развертки Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами