Каталог Sumitomo сплавы и режимы - страница 17

Навигация

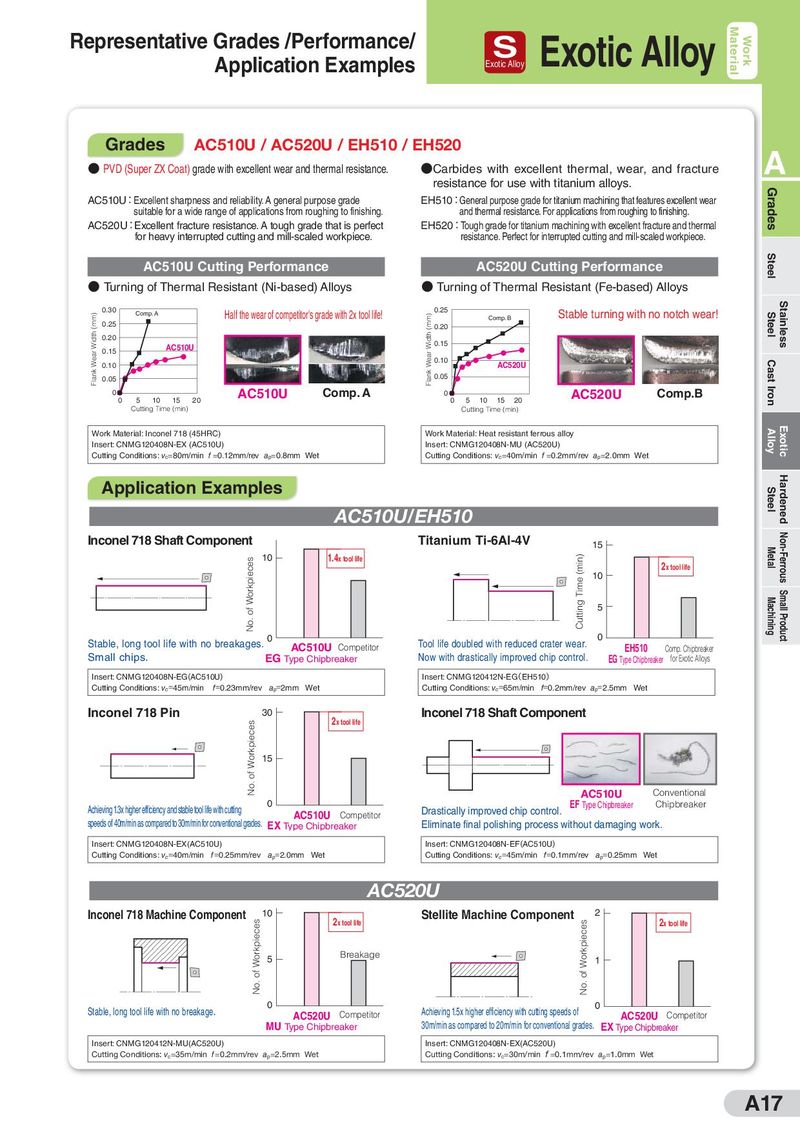

Representative Grades /Performance/ S Exotic Alloy Material Work Application Examples Exotic Alloy Grades AC510U / AC520U / EH510 / EH520 A ● PVD (Super ZX Coat) grade with excellent wear and thermal resistance. ●Carbides with excellent thermal, wear, and fracture resistance for use with titanium alloys. Grades AC510U:Excellent sharpness and reliability. A general purpose grade EH510:General purpose grade for titanium machining that features excellent wear suitable for a wide range of applications from roughing to finishing. and thermal resistance. For applications from roughing to finishing. AC520U:Excellent fracture resistance. A tough grade that is perfect EH520:Tough grade for titanium machining with excellent fracture and thermal for heavy interrupted cutting and mill-scaled workpiece. resistance. Perfect for interrupted cutting and mill-scaled workpiece. AC510U Cutting Performance AC520U Cutting Performance Steel ● Turning of Thermal Resistant (Ni-based) Alloys ● Turning of Thermal Resistant (Fe-based) Alloys (mm) 0.30 Comp. A Half the wear of competitor's grade with 2x tool life! (mm) 0.25 Stable turning with no notch wear! Steel Stainless 0.25 Comp. B 0.20 Width 0.20 Width 0.15 Wear 0.15 AC510U Wear 0.10 0.10 AC520U Cast Iron Flank 0.05 Flank 0.05 0 AC510U Comp. A 0 AC520U Comp.B 0 5 10 15 20 0 5 10 15 20 Cutting Time (min) Cutting Time (min) Work Material: Inconel 718 (45HRC) Work Material: Heat resistant ferrous alloy Alloy Exotic Insert: CNMG120408N-EX (AC510U) Insert: CNMG120408N-MU (AC520U) Cutting Conditions: vc=80m/min f =0.12mm/rev ap=0.8mm Wet Cutting Conditions: vc=40m/min f =0.2mm/rev ap=2.0mm Wet Application Examples Steel Hardened AC510U/EH510 Inconel 718 Shaft Component Titanium Ti-6Al-4V 15 Metal Non-Ferrous No. of Workpieces 10 1.4x tool life Cutting Time (min) 2x tool life 10 5 Machining Small Product Stable, long tool life with no breakages. 0 Tool life doubled with reduced crater wear. 0 AC510U Competitor EH510 Comp. Chipbreaker Small chips. EG Type Chipbreaker Now with drastically improved chip control. EG Type Chipbreaker for Exotic Alloys Insert: CNMG120408N-EG(AC510U) Insert: CNMG120412N-EG(EH510) Cutting Conditions: vc=45m/min f=0.23mm/rev ap=2mm Wet Cutting Conditions: vc=65m/min f=0.2mm/rev ap=2.5mm Wet Inconel 718 Pin 30 2x tool life Inconel 718 Shaft Component No. of Workpieces 15 AC510U Conventional Achieving 1.3x higher efficiency and stable tool life with cutting 0 Drastically improved chip control. EF Type Chipbreaker Chipbreaker speeds of 40m/min as compared to 30m/min for conventional grades. AC510U Competitor Eliminate final polishing process without damaging work. EX Type Chipbreaker Insert: CNMG120408N-EX(AC510U) Insert: CNMG120408N-EF(AC510U) Cutting Conditions: vc=40m/min f =0.25mm/rev ap=2.0mm Wet Cutting Conditions: vc=45m/min f=0.1mm/rev ap=0.25mm Wet AC520U Inconel 718 Machine Component 10 2x tool life Stellite Machine Component 2 No. of Workpieces No. of Workpieces 2x tool life 5 Breakage 1 Stable, long tool life with no breakage. 0 Achieving 1.5x higher efficiency with cutting speeds of 0 AC520U Competitor AC520U Competitor MU Type Chipbreaker 30m/min as compared to 20m/min for conventional grades. EX Type Chipbreaker Insert: CNMG120412N-MU(AC520U) Insert: CNMG120408N-EX(AC520U) Cutting Conditions: vc=35m/min f =0.2mm/rev ap=2.5mm Wet Cutting Conditions: vc=30m/min =0.1mm/rev ap=1.0mm Wet A17

Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Каталог Sumitomo сверла и развертки

Каталог Sumitomo сверла и развертки Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами