Каталог Sumitomo сплавы и режимы - страница 24

Навигация

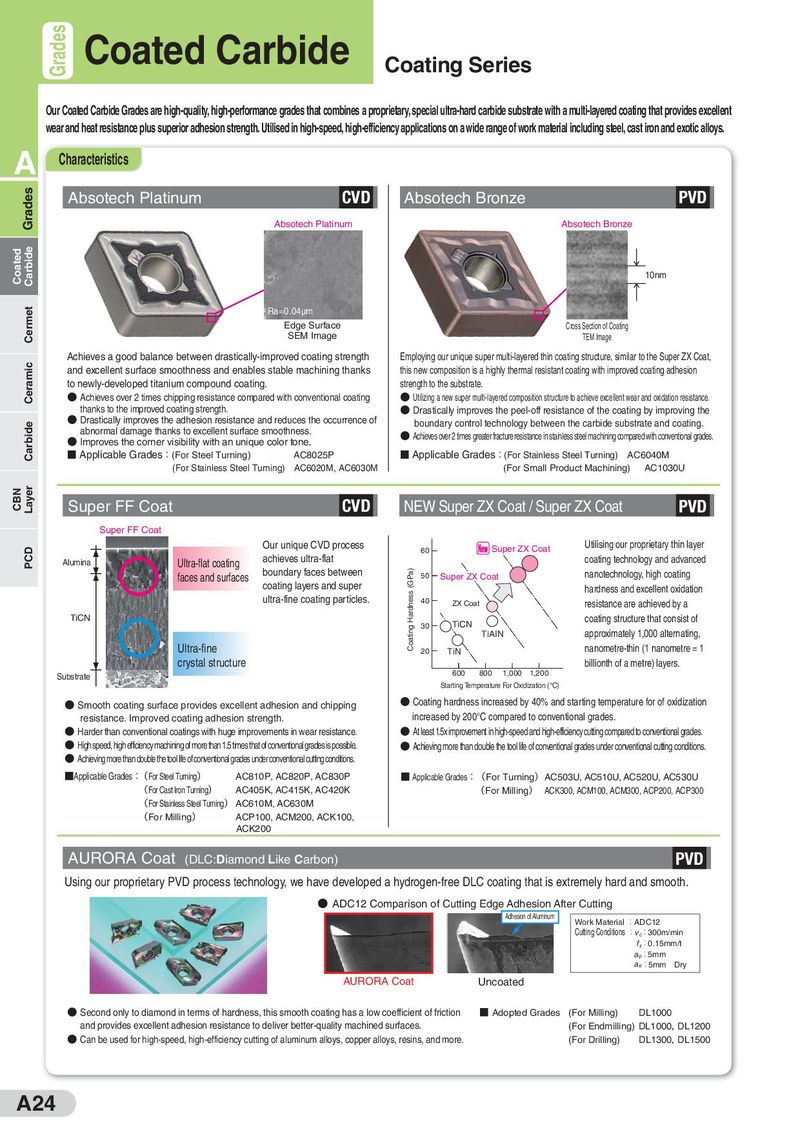

Grades Coated Carbide Coating Series Our Coated Carbide Grades are high-quality, high-performance grades that combines a proprietary, special ultra-hard carbide substrate with a multi-layered coating that provides excellent wear and heat resistance plus superior adhesion strength. Utilised in high-speed, high-efficiency applications on a wide range of work material including steel, cast iron and exotic alloys. A Characteristics Grades Absotech Platinum CVD Absotech Bronze PVD Absotech Platinum Absotech Bronze Coated Carbide 10nm Cermet Ra=0.04μm Edge Surface Cross Section of Coating SEM Image TEM Image Achieves a good balance between drastically-improved coating strength Employing our unique super multi-layered thin coating structure, similar to the Super ZX Coat, Ceramic and excellent surface smoothness and enables stable machining thanks this new composition is a highly thermal resistant coating with improved coating adhesion to newly-developed titanium compound coating. strength to the substrate. ● Achieves over 2 times chipping resistance compared with conventional coating ● Utilizing a new super multi-layered composition structure to achieve excellent wear and oxidation resistance. thanks to the improved coating strength. ● Drastically improves the peel-off resistance of the coating by improving the Carbide ● Drastically improves the adhesion resistance and reduces the occurrence of boundary control technology between the carbide substrate and coating. abnormal damage thanks to excellent surface smoothness. ● Achieves over 2 times greater fracture resistance in stainless steel machining compared with conventional grades. ● Improves the corner visibility with an unique color tone. ■ Applicable Grades:(For Steel Turning) AC8025P ■ Applicable Grades:(For Stainless Steel Turning) AC6040M (For Stainless Steel Turning) AC6020M, AC6030M (For Small Product Machining) AC1030U CBN Layer Super FF Coat CVD NEW Super ZX Coat / Super ZX Coat PVD Super FF Coat PCD Our unique CVD process 60 Super ZX Coat Utilising our proprietary thin layer Alumina Ultra-flat coating achieves ultra-flat coating technology and advanced faces and surfaces boundary faces between Coating Hardness (GPa) 50 Super ZX Coat nanotechnology, high coating coating layers and super hardness and excellent oxidation ultra-fine coating particles. 40 ZX Coat resistance are achieved by a TiCN TiCN coating structure that consist of 30 approximately 1,000 alternating, TiAIN Ultra-fine 20 TiN nanometre-thin (1 nanometre = 1 crystal structure billionth of a metre) layers. Substrate 600 800 1,000 1,200 Starting Temperature For Oxidization (°C) ● Smooth coating surface provides excellent adhesion and chipping ● Coating hardness increased by 40% and starting temperature for of oxidization resistance. Improved coating adhesion strength. increased by 200°C compared to conventional grades. ● Harder than conventional coatings with huge improvements in wear resistance. ● At least 1.5x improvement in high-speed and high-efficiency cutting compared to conventional grades. ● High speed, high efficiency machining of more than 1.5 times that of conventional grades is possible. ● Achieving more than double the tool life of conventional grades under conventional cutting conditions. ● Achieving more than double the tool life of conventional grades under conventional cutting conditions. ■Applicable Grades:(For Steel Turning) AC810P, AC820P, AC830P ■ Applicable Grades:(For Turning) AC503U, AC510U, AC520U, AC530U (For Cast Iron Turning) AC405K, AC415K, AC420K (For Milling) ACK300, ACM100, ACM300, ACP200, ACP300 (For Stainless Steel Turning) AC610M, AC630M (For Milling) ACP100, ACM200, ACK100, ACK200 AURORA Coat (DLC:Diamond Like Carbon) PVD Using our proprietary PVD process technology, we have developed a hydrogen-free DLC coating that is extremely hard and smooth. ● ADC12 Comparison of Cutting Edge Adhesion After Cutting Adhesion of Aluminum Work Material :ADC12 Cutting Conditions :vc:300m/min f z:0.15mm/t ap:5mm ae:5mm Dry AURORA Coat Uncoated ● Second only to diamond in terms of hardness, this smooth coating has a low coefficient of friction ■ Adopted Grades (For Milling) DL1000 and provides excellent adhesion resistance to deliver better-quality machined surfaces. (For Endmilling) DL1000, DL1200 ● Can be used for high-speed, high-efficiency cutting of aluminum alloys, copper alloys, resins, and more. (For Drilling) DL1300, DL1500 A24

Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Каталог Sumitomo сверла и развертки

Каталог Sumitomo сверла и развертки Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами