Каталог Sumitomo сплавы и режимы - страница 18

Навигация

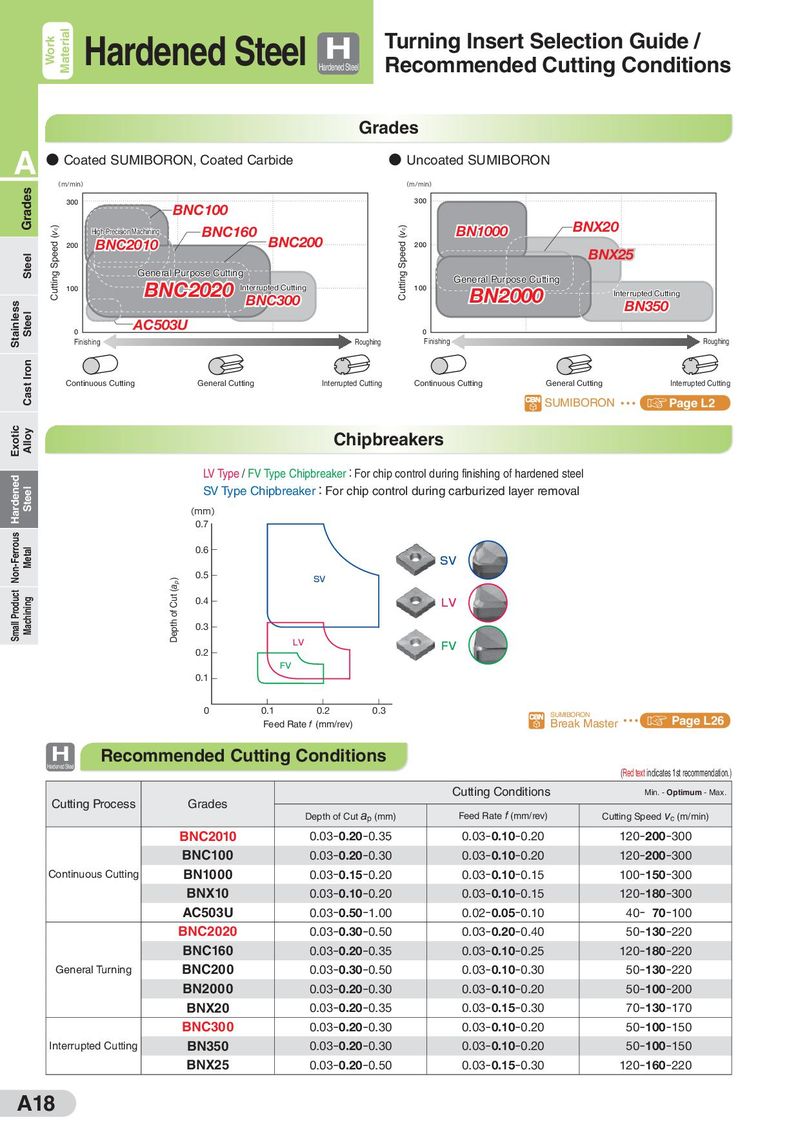

Work Material Hardened Steel H Turning Insert Selection Guide / Hardened Steel Recommended Cutting Conditions Grades A ● Coated SUMIBORON, Coated Carbide ● Uncoated SUMIBORON Grades (m/min) (m/min) 300 300 BNC100 (vc) High-Precision Machining BNC160 (vc) BN1000 BNX20 Cutting Speed 200 BNC2010 BNC200 Cutting Speed 200 Steel BNX25 General Purpose Cutting General Purpose Cutting 100 BNC2020 Interrupted Cutting 100 BN2000 Interrupted Cutting Stainless BNC300 BN350 Steel 0 AC503U 0 Finishing Roughing Finishing Roughing Cast Iron Continuous Cutting General Cutting Interrupted Cutting Continuous Cutting General Cutting Interrupted Cutting SUMIBORON Page L2 Exotic Alloy Chipbreakers Hardened LV Type / FV Type Chipbreaker:For chip control during finishing of hardened steel Steel SV Type Chipbreaker:For chip control during carburized layer removal (mm) 0.7 Non-Ferrous Metal 0.6 SV Depth of Cut (ap) 0.5 SV Small Product Machining 0.4 LV 0.3 LV FV 0.2 FV 0.1 0 0.1 0.2 0.3 SUMIBORON Feed Rate f (mm/rev) Break Master Page L26 H Recommended Cutting Conditions Hardened Steel (Red text indicates 1st recommendation.) Cutting Conditions Min. - Optimum - Max. Cutting Process Grades Depth of Cut ap (mm) Feed Rate f (mm/rev) Cutting Speed vc (m/min) BNC2010 0.03-0.20-0.35 0.03-0.10-0.20 120-200-300 BNC100 0.03-0.20-0.30 0.03-0.10-0.20 120-200-300 Continuous Cutting BN1000 0.03-0.15-0.20 0.03-0.10-0.15 100-150-300 BNX10 0.03-0.10-0.20 0.03-0.10-0.15 120-180-300 AC503U 0.03-0.50-1.00 0.02-0.05-0.10 40- 70-100 BNC2020 0.03-0.30-0.50 0.03-0.20-0.40 50-130-220 BNC160 0.03-0.20-0.35 0.03-0.10-0.25 120-180-220 General Turning BNC200 0.03-0.30-0.50 0.03-0.10-0.30 50-130-220 BN2000 0.03-0.20-0.30 0.03-0.10-0.20 50-100-200 BNX20 0.03-0.20-0.35 0.03-0.15-0.30 70-130-170 BNC300 0.03-0.20-0.30 0.03-0.10-0.20 50-100-150 Interrupted Cutting BN350 0.03-0.20-0.30 0.03-0.10-0.20 50-100-150 BNX25 0.03-0.20-0.50 0.03-0.15-0.30 120-160-220 A18

Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Каталог Sumitomo сверла и развертки

Каталог Sumitomo сверла и развертки Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами