Каталог Sumitomo сплавы и режимы - страница 26

Навигация

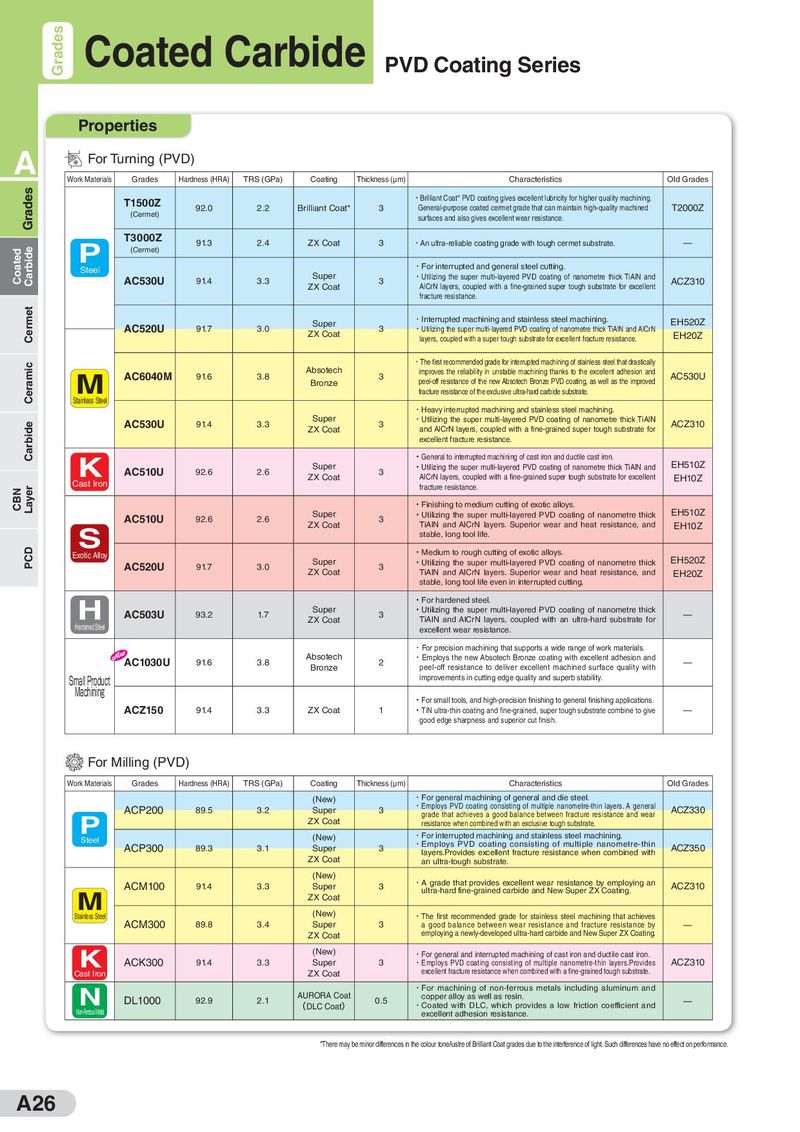

Grades Coated Carbide PVD Coating Series Properties A For Turning (PVD) Work Materials Grades Hardness (HRA) TRS (GPa) Coating Thickness (μm) Characteristics Old Grades Grades T1500Z ・Brilliant Coat* PVD coating gives excellent lubricity for higher quality machining. (Cermet) 92.0 2.2 Brilliant Coat* 3 General-purpose coated cermet grade that can maintain high-quality machined T2000Z surfaces and also gives excellent wear resistance. P T3000Z 91.3 2.4 ZX Coat 3 ・An ultra-reliable coating grade with tough cermet substrate. — Coated Carbide (Cermet) Steel ・For interrupted and general steel cutting. AC530U 91.4 3.3 Super 3 ・Utilizing the super multi-layered PVD coating of nanometre thick TiAlN and ACZ310 ZX Coat AlCrN layers, coupled with a fine-grained super tough substrate for excellent fracture resistance. Cermet Super ・Interrupted machining and stainless steel machining. EH520Z AC520U 91.7 3.0 ZX Coat 3 ・Utilizing the super multi-layered PVD coating of nanometre thick TiAlN and AlCrN EH20Z layers, coupled with a super tough substrate for excellent fracture resistance. Ceramic ・The first recommended grade for interrupted machining of stainless steel that drastically M AC6040M 91.6 3.8 Absotech 3 improves the reliability in unstable machining thanks to the excellent adhesion and AC530U Bronze peel-off resistance of the new Absotech Bronze PVD coating, as well as the improved fracture resistance of the exclusive ultra-hard carbide substrate. Stainless Steel ・Heavy interrupted machining and stainless steel machining. Carbide AC530U 91.4 3.3 Super 3 ・Utilizing the super multi-layered PVD coating of nanometre thick TiAlN ACZ310 ZX Coat and AlCrN layers, coupled with a fine-grained super tough substrate for excellent fracture resistance. K ・General to interrupted machining of cast iron and ductile cast iron. AC510U 92.6 2.6 Super 3 ・Utilizing the super multi-layered PVD coating of nanometre thick TiAlN and EH510Z Cast Iron ZX Coat AlCrN layers, coupled with a fine-grained super tough substrate for excellent EH10Z CBN Layer fracture resistance. ・Finishing to medium cutting of exotic alloys. AC510U 92.6 2.6 Super 3 ・Utilizing the super multi-layered PVD coating of nanometre thick EH510Z S ZX Coat TiAlN and AlCrN layers. Superior wear and heat resistance, and EH10Z stable, long tool life. PCD Exotic Alloy ・Medium to rough cutting of exotic alloys. AC520U 91.7 3.0 Super 3 ・Utilizing the super multi-layered PVD coating of nanometre thick EH520Z ZX Coat TiAlN and AlCrN layers. Superior wear and heat resistance, and EH20Z stable, long tool life even in interrupted cutting. H ・For hardened steel. AC503U 93.2 1.7 Super 3 ・Utilizing the super multi-layered PVD coating of nanometre thick — Hardened Steel ZX Coat TiAlN and AlCrN layers, coupled with an ultra-hard substrate for excellent wear resistance. ・For precision machining that supports a wide range of work materials. AC1030U 91.6 3.8 Absotech 2 ・Employs the new Absotech Bronze coating with excellent adhesion and — Bronze peel-off resistance to deliver excellent machined surface quality with Small Product improvements in cutting edge quality and superb stability. Machining ・For small tools, and high-precision finishing to general finishing applications. ACZ150 91.4 3.3 ZX Coat 1 ・TiN ultra-thin coating and fine-grained, super tough substrate combine to give — good edge sharpness and superior cut finish. For Milling (PVD) Work Materials Grades Hardness (HRA) TRS (GPa) Coating Thickness (μm) Characteristics Old Grades (New) ・For general machining of general and die steel. ACP200 89.5 3.2 Super 3 ・Employs PVD coating consisting of multiple nanometre-thin layers. A general ACZ330 P ZX Coat grade that achieves a good balance between fracture resistance and wear resistance when combined with an exclusive tough substrate. Steel (New) ・For interrupted machining and stainless steel machining. ACP300 89.3 3.1 Super 3 ・Employs PVD coating consisting of multiple nanometre-thin ACZ350 ZX Coat layers.Provides excellent fracture resistance when combined with an ultra-tough substrate. (New) ・A grade that provides excellent wear resistance by employing an ACM100 91.4 3.3 Super 3 ultra-hard fine-grained carbide and New Super ZX Coating. ACZ310 M ZX Coat Stainless Steel (New) ・The first recommended grade for stainless steel machining that achieves ACM300 89.8 3.4 Super 3 a good balance between wear resistance and fracture resistance by ̶ ZX Coat employing a newly-developed ultra-hard carbide and New Super ZX Coating. K (New) ・For general and interrupted machining of cast iron and ductile cast iron. ACK300 91.4 3.3 Super 3 ・Employs PVD coating consisting of multiple nanometre-thin layers.Provides ACZ310 Cast Iron ZX Coat excellent fracture resistance when combined with a fine-grained tough substrate. N AURORA Coat ・For machining of non-ferrous metals including aluminum and DL1000 92.9 2.1 0.5 copper alloy as well as resin. ̶ Non-Ferrous Metal (DLC Coat) ・Coated with DLC, which provides a low friction coefficient and excellent adhesion resistance. *There may be minor differences in the colour tone/lustre of Brilliant Coat grades due to the interference of light. Such differences have no effect on performance. A26

Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Каталог Sumitomo сверла и развертки

Каталог Sumitomo сверла и развертки Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами