Каталог Sumitomo сплавы и режимы - страница 16

Навигация

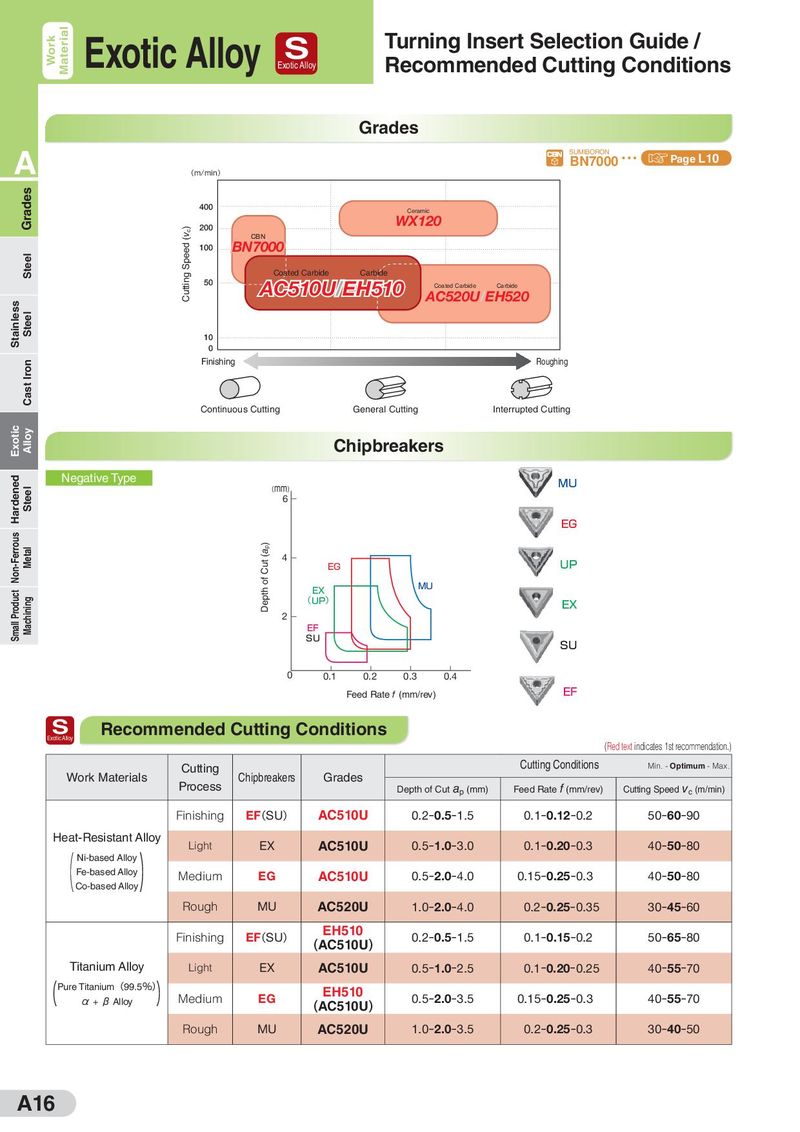

Work Material Exotic Alloy S Turning Insert Selection Guide / Exotic Alloy Recommended Cutting Conditions Grades A SUMIBORON Page L10 BN7000 (m/min) Grades 400 Ceramic 200 WX120 (vc) CBN Cutting Speed 100 BN7000 Steel Coated Carbide Carbide 50 AC510U/EH510 Coated Carbide Carbide Stainless AC520U/EH520 Steel 10 0 Cast Iron Finishing Roughing Continuous Cutting General Cutting Interrupted Cutting Exotic Alloy Chipbreakers Hardened Negative Type MU Steel (mm) 6 EG Non-Ferrous Metal of Cut (ap) 4 UP EG Small Product Depth EX MU Machining (UP) EX 2 EF SU SU 0 0.1 0.2 0.3 0.4 Feed Rate f (mm/rev) EF S Recommended Cutting Conditions Exotic Alloy (Red text indicates 1st recommendation.) Cutting Cutting Conditions Min. - Optimum - Max. Work Materials Process Chipbreakers Grades Depth of Cut ap (mm) Feed Rate f (mm/rev) Cutting Speed vc (m/min) Finishing EF(SU) AC510U 0.2-0.5-1.5 0.1-0.12-0.2 50-60-90 Heat-Resistant Alloy Light EX AC510U 0.5-1.0-3.0 0.1-0.20-0.3 40-50-80 ( ) Ni-based Alloy Fe-based Alloy Medium EG AC510U 0.5-2.0-4.0 0.15-0.25-0.3 40-50-80 Co-based Alloy Rough MU AC520U 1.0-2.0-4.0 0.2-0.25-0.35 30-45-60 Finishing EF(SU) EH510 0.2-0.5-1.5 0.1-0.15-0.2 50-65-80 (AC510U) Titanium Alloy Light EX AC510U 0.5-1.0-2.5 0.1-0.20-0.25 40-55-70 ( ) Pure Titanium(99.5%) Medium EG EH510 0.5-2.0-3.5 0.15-0.25-0.3 40-55-70 α + β Alloy (AC510U) Rough MU AC520U 1.0-2.0-3.5 0.2-0.25-0.3 30-40-50 A16

Каталог Sumitomo токарные резцы (державки) для наружного точения

Каталог Sumitomo токарные резцы (державки) для наружного точения Каталог Sumitomo сверла и развертки

Каталог Sumitomo сверла и развертки Каталог Sumitomo запасные части

Каталог Sumitomo запасные части Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами