Общий каталог TooTool - страница 98

Навигация

- 页 1

- 页 2

- 页 3

- 页 4

- 页 5

- 页 6

- 页 7

- 页 8

- 页 9

- 页 10

- 页 11

- 页 12

- 页 13

- 页 14

- 页 15

- 页 16

- 页 17

- 页 18

- 页 19

- 页 20

- 页 21

- 页 22

- 页 23

- 页 24

- 页 25

- 页 26

- 页 27

- 页 28

- 页 29

- 页 30

- 页 31

- 页 32

- 页 33

- 页 34

- 页 35

- 页 36

- 页 37

- 页 38

- 页 39

- 页 40

- 页 41

- 页 42

- 页 43

- 页 44

- 页 45

- 页 46

- 页 47

- 页 48

- 页 49

- 页 50

- 页 51

- 页 52

- 页 53

- 页 54

- 页 55

- 页 56

- 页 57

- 页 58

- 页 59

- 页 60

- 页 61

- 页 62

- 页 63

- 页 64

- 页 65

- 页 66

- 页 67

- 页 68

- 页 69

- 页 70

- 页 71

- 页 72

- 页 73

- 页 74

- 页 75

- 页 76

- 页 77

- 页 78

- 页 79

- 页 80

- 页 81

- 82: 新增页码2

- 页 83

- 页 84

- 页 85

- 页 86

- 页 87

- 页 88

- 页 89

- 页 90

- 页 91

- 页 92

- 页 93

- 页 94

- 页 95

- 页 96

- 页 97

- 页 98

- 页 99

- 页 100

- 页 101

- 页 102

- 页 103

- 页 104

- 页 105

- 页 106

- 页 107

- 页 108

- 页 109

- 页 110

- 页 111

- 页 112

- 页 113

- 页 114

- 页 115

- 页 116

- 页 117

- 页 118

- 页 119

- 页 120

- 页 121

- 页 122

- 页 123

- 页 124

- 页 125

- 页 126

- 页 127

- 页 128

- 页 129

- 页 130

- 页 131

- 页 132

- 页 133

- 页 134

- 页 135

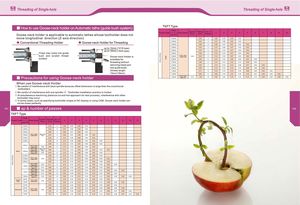

E Threading of Single-hole Threading of Single-hole E How to use Goose-neck holder on Automatic lathe (guide bush system) TKFT Type Goose-neck holder is applicable to automatic lathes whose toolholder does not Thread Type Pitchmm/TPIDescription Corner-R(re) Total ap(mm) No. ofPasses 1 2 3 4 5 6 7 8 9 10 move longitudinal direction ( Z-axis direction) 0.20mm 0.20 4 0.08 0.06 0.04 0.02 •Conventional Threading Holder # Goose-neck Holder for Threading 0.25mm 0.24 4 0.10 0.08 0.04 0.020.30mm0.2850.080.070.070.040.02 \9/ r Chips may bush and surface come into guide scratch thread \3 up to 15mm (1216 type)up to 19mm (1620 type)Goose-neck Holder is7javailable forthreading without 0.35mm 0.32 5 0.10 0.09 0.07 0.04 0.020.40mm0.3550.120.100.070.040.02m0.45mm0.3950.160.100.070.040.02CD032CD0.50mmCTPT 11R/LA /B6 0 -0 0 50.050.3350.100.100.070.040.023-O0.60mm0.4060.100.100.080.060.040.0203CL0.70mm0.4860.100.100.100.100.060.02 returning tread part 0.75mm 0.52 7 0.10 0.10 0.10 0.08 0.07 0.05 0.02 into guide bush, 0.80mm 0.56 7 0.10 0.10 0.10 0.10 0.08 0.06 0.02 (thread length 1.00mm 0.71 8 0.15 0.15 0.12 0.10 0.08 0.06 0.03 0.02 15mm/19mm) 1.25mm 0.90 9 0.20 0.18 0.13 0.10 0.10 0.07 0.05 0.05 0.02 Precautions for using Goose-neck holder 1,50mm CTPT 11R/LN60-010 0.10 1.09 10 0.22 0.20 0.15 0.12 0.10 0.10 0.08 0.05 0.05 0.02 When use Goose-neck Holder ® Be careful of interference with back spindle because offset dimension is large than the coventional toolholders (D Be careful of interference with sub spindle =}> Toolholder installation position is limited. @ At simultaneous machining (balance cut and tool approach for next process), interference with other toolholder may occur. @ In some cases, such as specifying toolholder shape on NC display or using CAM, Goose-neck holder can not be drawn perfectly 191 ap & number of passes 192 TKFT Type Thread Type Pitch mm/TPI Description Corner- R(re) Total ap(mm) No. ofPasses 1 2 3 4 5 6 7 8 9 10 11 0.20mm 0.15 4 0.06 0.04 0.03 0.02 0.25mm 0.19 4 0.07 0.06 0.04 0.02 0.30mm 0.23 4 0.08 0.07 0.06 0.02 0.35mm TKFT 12R/L Max 0.05A/B60-000Flat0.27 5 0.08 0.07 0.06 0.04 0.02 0.40mm 0.30 5 0.10 0.08 0.06 0.04 0.02 0.45mm 0.34 6 0.10 0.08 0.06 0.04 0.04 0.02 0.38 6 0.10 0.10 0.07 0.05 0.04 0.02 0.50mm TKFT 12R/LA/B60-0050.05 0.33 5 0.10 0.10 0.07 0.04 0.02 TKFT 12R/L Max 0.05Metric0.60mmA/B60-000TKFT 12R/LA/B60-005Flat0.050.450.40760.100.100.080.06 0.05 0.04 0.020.100.100.080.060.040.02 m 0.70mm 0.48 6 0.10 0.10 0.10 0.10 0.06 0.02 CD03 0.75mm TKFT 12R/LA/B60-0050.05 0.52 7 0.10 0.10 0.10 0.08 0.07 0.05 0.02 1 3" 0.80mm 0.56 7 0.10 0.10 0.10 0.10 0.08 0.06 0.02 3 TKFT 12R/L1.00mmA/B60-005TKFT 12R/LN60-0100.050.100.710.66860.15 0.15 0.12 0.10 0.08 0.06 0.03 0.020.180.150.120.100.060.030.02 TKFT 12R/L1,25mmA/B60-005TKFT 12R/LN60-0100.050.100.900.85980.20 0.18 0.13 0.10 0.10 0.07 0.05 0.05 0.020.200.180.130.100.100.070.050.02 1,50mm TKFT 12R/LN60-010 0.10 1.04 10 0.20 0.18 0.14 0.12 0.10 0.10 0.08 0.05 0.05 0.02 Parallel 28 TPI TKFT 12R/LPipe19 TPIA/B55-0050.050.671.01 79 0.18 0.15 0.12 0.10 0.06 0.04 0.020.200.180.140.120.120.100.080.050.02 24 TPI 0.79 8 0.18 0.18 0.12 0.10 0.08 0.07 0.04 0.02 20 TPIWhitworth18 TPITKFT 12R/LA/B55-0050.050.961.07 910 0.20 0.20 0.15 0.10 0.10 0.08 0.06 0.05 0.020.200.180.150.120.100.100.080.070.050.02 16 TPI 1.21 11 0.20 0.18 0.15 0.15 0.12 0.10 0.10 0.08 0.07 0.04 0.02

Каталог TooTool техническая информация 1

Каталог TooTool техническая информация 1 Каталог TooTool монолитные фрезы

Каталог TooTool монолитные фрезы Каталог TooTool техническая информация 2

Каталог TooTool техническая информация 2