Общий каталог TooTool - страница 4

Навигация

- 页 1

- 页 2

- 页 3

- 页 4

- 页 5

- 页 6

- 页 7

- 页 8

- 页 9

- 页 10

- 页 11

- 页 12

- 页 13

- 页 14

- 页 15

- 页 16

- 页 17

- 页 18

- 页 19

- 页 20

- 页 21

- 页 22

- 页 23

- 页 24

- 页 25

- 页 26

- 页 27

- 页 28

- 页 29

- 页 30

- 页 31

- 页 32

- 页 33

- 页 34

- 页 35

- 页 36

- 页 37

- 页 38

- 页 39

- 页 40

- 页 41

- 页 42

- 页 43

- 页 44

- 页 45

- 页 46

- 页 47

- 页 48

- 页 49

- 页 50

- 页 51

- 页 52

- 页 53

- 页 54

- 页 55

- 页 56

- 页 57

- 页 58

- 页 59

- 页 60

- 页 61

- 页 62

- 页 63

- 页 64

- 页 65

- 页 66

- 页 67

- 页 68

- 页 69

- 页 70

- 页 71

- 页 72

- 页 73

- 页 74

- 页 75

- 页 76

- 页 77

- 页 78

- 页 79

- 页 80

- 页 81

- 82: 新增页码2

- 页 83

- 页 84

- 页 85

- 页 86

- 页 87

- 页 88

- 页 89

- 页 90

- 页 91

- 页 92

- 页 93

- 页 94

- 页 95

- 页 96

- 页 97

- 页 98

- 页 99

- 页 100

- 页 101

- 页 102

- 页 103

- 页 104

- 页 105

- 页 106

- 页 107

- 页 108

- 页 109

- 页 110

- 页 111

- 页 112

- 页 113

- 页 114

- 页 115

- 页 116

- 页 117

- 页 118

- 页 119

- 页 120

- 页 121

- 页 122

- 页 123

- 页 124

- 页 125

- 页 126

- 页 127

- 页 128

- 页 129

- 页 130

- 页 131

- 页 132

- 页 133

- 页 134

- 页 135

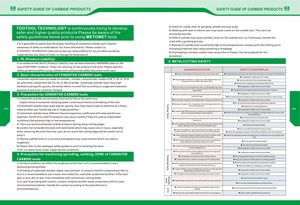

SAFETY GUIDE OF CARBIDE PRODUCTS H TOOTOOL TECHNOLOGY is continuously trying to develop 4) Check for cracks after re-grinding carbide tool and reuse. 5) Marking with laser or electric pen may cause cracks on the carbide tool. The crack can safer and higher quality products Please be aware of the shortened tool life. safety guidelines below prior to using METOMET tools. 6) EDM of carbide may cause residual cracks on the carbide tool, so if necessary, remove the crack with a grinding process. •It is generally accepted that the proper handling of cemented carbide tools requires 7) Brazing of carbide tools at extremly high or low temperatures compare with the melting point awareness of safety as noted above. For more information. Please contact us. of brazing materials may cause loosening or breakage. •TOOTOOL TECHNOLOGY does not accept any responsibility for any accident caused by 8) Overheating a oil base coolant may cause a fire or flames, thus be prepared for fire inappropriate use, about of tools, or changes to the products. prevention. 1. PL (Product Liability) In accordance with the PL (Product Liablility) law, we have attached a WARNING label on the 5. METALCUTTING SAFETY case of METOMET products. There isno warning on the surface of the tools. Please read this safety guidelines before using carbide tools and provide safety education to all users. DANGEROUS FACTOR SAFETY COUNTERPLAN 2. Basic characteristics of CEMENTED CARBIDE toolsCemented carbide tools are made of carbides , nitrides, carbonitrides, oxides of W, Ti, Al, Si, Ta, Betc and metal component like CO, Ni, Cr, Mo as binder. Cemented carbides tools have high •Sharp cutting edge of cutting tools may cut your bare-hand •Use gloves when pulling out the insert from the case or mounting it on the machine•Inappropriate conditions or usage may cuase fragmentation andexpel parts of tools which may cause injury•Use glasses or safety cover for safety•Use the tools within the recommended range•Please refer to catalogue and safety guidelines first. hardness and sepcific gravity. Generally there's no smell but according to usage and treatment, •Severe load on tool and premature wear of cutting edge may bring •Use glasses or safety cover for your safety appreance and color could be changed. excessive cutting force on tools, causing fracutre of the tool and maycause injury •Change the tool as required before excessive wear or fracutre 3. Precaution for CEMENTED CARBIDE tools1) Cemented carbides are extremely hard and brittle at the same time. •Chips evacuated during cutting are hot and sharp and may causeburns and cuts •Use glasses or safety cover for your safety•Stop machining and put safety glove on and use a hook tool to remove chips•Touching the workpiece immediately after cutting may cause burns•Use gloves or safety cover for your safety Impact shock or excessive clamping power could cause fracture orbreaking of the tool.2) Cemented carbides have large specific gravity, thus they require special attention as a heavyo c •Be aware of sparks, fire, the or explosion of hot cutting operation. chips generated during •Do not use at the place where having explosive materials•Prepare for fire extinguishments 003 material when you handle big size or large quantities.3) Cemented carbides have different thermal expansion coefficient with steel and ferrous D CQ •In case of high RPM machining, vibration and chattering may occurdue to the improper balance of the machine•Use glasses or safety cover for your safety•Check first if there's any chattering, vibration or strange noises prior to your main004Ocutting operation materials. Shrink fit or swell fit products may cause trouble if they are used at undesirableconditions like extremly high or low temperatures. O C/) •Touching a burr remaining on the workpiece with a bare-hand maycause a cut •Do not touch the burr with bare-hand•Use glaoves or safety cover for your safety 4) There are several cemented carbide products having sharp cutting edges. •Loose clamping of the workpiece may cause the tool to fracture andresult in damage to the cutter body and possible injury•Clamp the workpiece tightly Be careful not to handle the tools with bare hands which may cause cuts or injury, especiallywhen removing the tools from the case, do not touch the cutting edge and be careful not to •Tools are operated to right-hand direction normally. Left-handdirection operation can cause fracture of tool and body damage•Do not use left-hand direction without notice•Check the package of product to check the availability of left-hand operation drop it. •Loose clamping of inserts and parts may result in ejection of thetool during cutting and may cuase serious injury•Check the clamping of inserts and parts prior to machining, and use original partsonly 5) Storing carbide tools in a corrosive atmosphere may cause erosion which can reducetoughness. •Over loaded clamping of inserts by a lever (such as a pipe) maycause dangerous fracturing of parts and inserts•Do not use lever inappropriately 6) Please refer to the catalogue safety guidance prior to handling the tools.7) Do not absue tools under inappropriate conditions.4. Precaution for machining (grinding, welding, EDM) of CEMENTEDCARBIDE tools •In case of high speed machining, parts and inserts can be forcedout by centrifugal force •Use within recommended condition•Use glasses or safety cover for your safety•Since cutter has sharp cutting edges touching with a bare-handmay cuase a cut•Use gloves or safety cover for your safety7JOQ)•It is dangerous to use glove with rotating machine•Contact with body or clothes is dangerous with rotating parts•Do not wear gloves when you work with rotating machine•Keep your body and clothes away from rotating machine 1) Surface condition can affect the toughness of the tool, so it is recommended to use adiamond grinding wheel.2) Grinding of cemented carbide creates mist and dust. It contains harmful compositions like Co, CQ •Vibration generated by balancing trouble may cuase a fracture andejection of the tool which may cuase serious injuryO•RPM should be controled within recommended condition•Check the balance of rotating part periodicallyOcn•In case of drilling, the uncut bottom core can fly out of the part withhigh speed and cause serious injury•Use gloves or safety cover for your safety thus it is recommended to use a mask, mist collection, and other protective facilities. If the dust •The deges of small diameter drill are sharp and easy to break •Use gloves or safety cover for your safety gets in your skin or eye, rinse immeditely with continously running water.3) In case of grinding with coolant, coolant contains harmful metal components which cuaseenvironmental problems. Handle the coolant according to the manufacturer'sr e c o m m e n d a t i o n s.OO3ft•Fragmentation and ejection of brazed carbide tip may cause injury(/)CDQ. •Check the brazed tip before using•Do not use at high temperature cutting conditionm•There's a possibility of breaking the carbide tip after severalbrazing•Do not use brazing a tip that has been brazed several times o •Abusing may cause fragmentation of tool and is very dangerous •Stick to safety regulations and guidelines

Каталог TooTool техническая информация 1

Каталог TooTool техническая информация 1 Каталог TooTool монолитные фрезы

Каталог TooTool монолитные фрезы Каталог TooTool техническая информация 2

Каталог TooTool техническая информация 2