Общий каталог TooTool - страница 10

Навигация

- 页 1

- 页 2

- 页 3

- 页 4

- 页 5

- 页 6

- 页 7

- 页 8

- 页 9

- 页 10

- 页 11

- 页 12

- 页 13

- 页 14

- 页 15

- 页 16

- 页 17

- 页 18

- 页 19

- 页 20

- 页 21

- 页 22

- 页 23

- 页 24

- 页 25

- 页 26

- 页 27

- 页 28

- 页 29

- 页 30

- 页 31

- 页 32

- 页 33

- 页 34

- 页 35

- 页 36

- 页 37

- 页 38

- 页 39

- 页 40

- 页 41

- 页 42

- 页 43

- 页 44

- 页 45

- 页 46

- 页 47

- 页 48

- 页 49

- 页 50

- 页 51

- 页 52

- 页 53

- 页 54

- 页 55

- 页 56

- 页 57

- 页 58

- 页 59

- 页 60

- 页 61

- 页 62

- 页 63

- 页 64

- 页 65

- 页 66

- 页 67

- 页 68

- 页 69

- 页 70

- 页 71

- 页 72

- 页 73

- 页 74

- 页 75

- 页 76

- 页 77

- 页 78

- 页 79

- 页 80

- 页 81

- 82: 新增页码2

- 页 83

- 页 84

- 页 85

- 页 86

- 页 87

- 页 88

- 页 89

- 页 90

- 页 91

- 页 92

- 页 93

- 页 94

- 页 95

- 页 96

- 页 97

- 页 98

- 页 99

- 页 100

- 页 101

- 页 102

- 页 103

- 页 104

- 页 105

- 页 106

- 页 107

- 页 108

- 页 109

- 页 110

- 页 111

- 页 112

- 页 113

- 页 114

- 页 115

- 页 116

- 页 117

- 页 118

- 页 119

- 页 120

- 页 121

- 页 122

- 页 123

- 页 124

- 页 125

- 页 126

- 页 127

- 页 128

- 页 129

- 页 130

- 页 131

- 页 132

- 页 133

- 页 134

- 页 135

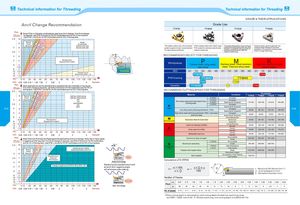

Technical information for Threading Technical information for Threading

GRADE & THEIR APPLICATIONS

Anvil Change Recommendation Grade Use

TTIP30 TTIM45 TTIG30 TTIN30

Pitch

A Some Pitch to Diameter combinations require an Anvil change. If an Anvil change

TPI mm is required , use STM- R Anvils for EX-RH toolholders and for IN-LH boring bars.

Use STM-L Anvils for IN- RH toolholders and for EX-LH boring bars.

2.5 109 Special 5Holderv I I iACMESTUB ACME

3 83.57 Required v/ AC Co AC o£ ^V//o- rC *< V, 7 / TRAPEZ (DIN 103)ROUND (DIN 405) TiN coated , yellow color, the universal TiALN coated, black color; Multi-Layer The grade designation is according to Ceramic grade, good toughness, thegrade for general steel, recommendedPVD coated for stainless steel & steelfor rigid cutting conditional.medium machiningpressing thread inserts with new chip-breaker, compatible with all series ofstainless steel & steel < HRC 50medium machiningcollapse edge resistance and wearresistance. It is good for ordinary steelfinish to rough machining

4 6 CO/KZZ / 'T' Co RECOMMENDED SELECT FORTHREADING

5 5 ^/ Standard Anvil(Supplied With Holder)64 pWorkpiecesCarbon steel, alloy steelStailess steel, Heat tesistant

3.5 cast steel steel, Titanium alloy steel

8 3

10 2.5 iso 01 10 20 30 40 01 10 20 30 40

12 2161.5>77 Change to anvilSTM-R 1Nor STM-L 1N misftm

mm: 5 10 20 30 40 50 60 70 80 90 100 1 10 120 130 140Inch:0.250.500.7511.251.5022.50345Diameter PVD Coating 9

Pitch A Most applications use the standard Anvil supplied with the toolholder or boring bar. Ceramic IEKHB

TPI mm If an Anvil change is required, use STM- R Anvils for EX-RH toolholders and for IN-LH

boring bars. Use STM-L Anvils for IN- RH toolholders and for EX-LH boring bars. RECOMMEND CUTTING SPEED FORTHREADING

2.5 10 Q. 05

Каталог TooTool техническая информация 1

Каталог TooTool техническая информация 1 Каталог TooTool монолитные фрезы

Каталог TooTool монолитные фрезы Каталог TooTool техническая информация 2

Каталог TooTool техническая информация 2