Общий каталог TooTool - страница 61

Навигация

- 页 1

- 页 2

- 页 3

- 页 4

- 页 5

- 页 6

- 页 7

- 页 8

- 页 9

- 页 10

- 页 11

- 页 12

- 页 13

- 页 14

- 页 15

- 页 16

- 页 17

- 页 18

- 页 19

- 页 20

- 页 21

- 页 22

- 页 23

- 页 24

- 页 25

- 页 26

- 页 27

- 页 28

- 页 29

- 页 30

- 页 31

- 页 32

- 页 33

- 页 34

- 页 35

- 页 36

- 页 37

- 页 38

- 页 39

- 页 40

- 页 41

- 页 42

- 页 43

- 页 44

- 页 45

- 页 46

- 页 47

- 页 48

- 页 49

- 页 50

- 页 51

- 页 52

- 页 53

- 页 54

- 页 55

- 页 56

- 页 57

- 页 58

- 页 59

- 页 60

- 页 61

- 页 62

- 页 63

- 页 64

- 页 65

- 页 66

- 页 67

- 页 68

- 页 69

- 页 70

- 页 71

- 页 72

- 页 73

- 页 74

- 页 75

- 页 76

- 页 77

- 页 78

- 页 79

- 页 80

- 页 81

- 82: 新增页码2

- 页 83

- 页 84

- 页 85

- 页 86

- 页 87

- 页 88

- 页 89

- 页 90

- 页 91

- 页 92

- 页 93

- 页 94

- 页 95

- 页 96

- 页 97

- 页 98

- 页 99

- 页 100

- 页 101

- 页 102

- 页 103

- 页 104

- 页 105

- 页 106

- 页 107

- 页 108

- 页 109

- 页 110

- 页 111

- 页 112

- 页 113

- 页 114

- 页 115

- 页 116

- 页 117

- 页 118

- 页 119

- 页 120

- 页 121

- 页 122

- 页 123

- 页 124

- 页 125

- 页 126

- 页 127

- 页 128

- 页 129

- 页 130

- 页 131

- 页 132

- 页 133

- 页 134

- 页 135

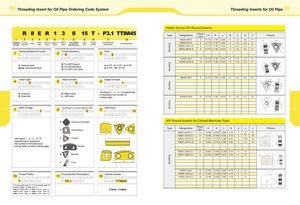

Threading Insert for Oil Pipe Ordering Code System Threading Inserts for Oil Pipe Helter Series API Round Inserts R 8 E R 1 3 S 15 T - P3.1 TTIM45 Type Designation Pitch( tpi )I.C H L B C d Y Picture 2 3M4 5 6 7 8 9 10 11 12 R 8 ER 2.3 B 10 T 8 10.170 17.09 0.320 6 4.5 4.2 5° Cmlaemthpoindgof insertThreadstandardPitchInserttypeHand ofEdqaes ofinsertinsertTeeth ofedgeInsert Shapeor used formachine toolsInsertsizeThreadprofileCharacteristicparametersCarbide grades m R 8 ER 2.3 B1 OF 8 10.170 17.09 0.320 6 4.5 4.2 5°xR 8ER2.3B10T-N810.17017.090.01064.54.25° 0 3 R 8 ER 2.3 B 10F - N 8 10.170 17.09 0.010 6 4.5 4.2 5° Calmping Method of Insert Thread Standard Pitch 0) R 8 R10ER 2.4 B10 10 10.170 17.09 0.010 6 4.5 4.2 5° m R10ER 2.4B10 - N 10 10.170 17.09 0.010 6 4.5 4.2 5° V: Vertical styleNone: Horizontal style R: For API RoundB: For API ButtressG: For API Line Type4: 4 TPI 5: 5 TPI 6: 6 TPI8: 8 TPI10: 10 TPI x 0 3 Q) R 8NR2.3B10 8 10.170 17.09 0.320 6 4.5 4.2 10° Insert Type Hand of Insert Edges of Insert E R 1 3 0 X 3 03 E: ExternalN: Insertnal R: Right handL: Left hand Use figured 2> 3. 4 respectivelyto represent the number ofcutting edge. R 1 0 NR 2.4 B 10 10 10.170 17.09 0.010 6 4.5 4.2 10° 3 7 0 i 3 Teeth of Edge Insert Shape or Used for Machine Tools 0) 3 S S: Square and rectangle API Round Inserts for Colinet Machine Tools aP: Parallelogram Type Designation Pitch( tpi ) A H L B d a A PictureR 8 ER1.3 S 15 F - 2.1815.76015.5405.9804.7646°15°L X Use figured 2^ 3. 4—8respectively to represent T: Ev Triangle R 8 ER1.3 S 15 F - 2.2 8 15.760 15.860 4.393 4.76 4 6° 15° iR 8 ER 1.3 S15T- KX815.87515.7504.3885.0045 ° 3012°R 8 ER1.3 S 15 T-LB815.93015.7504.4005.0046°12° the number of simultaneous cutting teeth on each cutting edge Biforate A R 8 ER 1.3 S 20 T-2.1 8 20.000 15.600 10.200 4.76 4 6° B: Butterfly m R 8 ER 1.3 S 20 T-2.2 8 20.000 15.900 8.610 4.76 4 6° X / Prism 0 Q) R 10 ER1.3 S 15 10 15.760 15.450 4.400 4.76 4 6° Thread Profile Characteristic Parameters Carbide Grades10 R 10 ER 1.3 S 15 -2.1 10 15.760 15.160 15.760 4.76 4 6° iiR 10 ER 1.3 S 15 - 2.21015.76015.4504.4004.7646° T P3.1 TTIM45 T: Thread profile angle 12° F: Thread profile angle 15° A D: BCSG V384: V-0.038R Taper 1:4 V386: V-0.038R Taper 1:6 V404: V-0.040 Taper 1:4 TTIP30 TTIM45 V504: V-0.050 Taper 1:4 V506: V-0.050 Taper 1:6 V558: V-0.055 Taper 1:8 V656: V-0.065 Taper 1:6

Каталог TooTool техническая информация 1

Каталог TooTool техническая информация 1 Каталог TooTool монолитные фрезы

Каталог TooTool монолитные фрезы Каталог TooTool техническая информация 2

Каталог TooTool техническая информация 2