Общий каталог TooTool - страница 11

Навигация

- 页 1

- 页 2

- 页 3

- 页 4

- 页 5

- 页 6

- 页 7

- 页 8

- 页 9

- 页 10

- 页 11

- 页 12

- 页 13

- 页 14

- 页 15

- 页 16

- 页 17

- 页 18

- 页 19

- 页 20

- 页 21

- 页 22

- 页 23

- 页 24

- 页 25

- 页 26

- 页 27

- 页 28

- 页 29

- 页 30

- 页 31

- 页 32

- 页 33

- 页 34

- 页 35

- 页 36

- 页 37

- 页 38

- 页 39

- 页 40

- 页 41

- 页 42

- 页 43

- 页 44

- 页 45

- 页 46

- 页 47

- 页 48

- 页 49

- 页 50

- 页 51

- 页 52

- 页 53

- 页 54

- 页 55

- 页 56

- 页 57

- 页 58

- 页 59

- 页 60

- 页 61

- 页 62

- 页 63

- 页 64

- 页 65

- 页 66

- 页 67

- 页 68

- 页 69

- 页 70

- 页 71

- 页 72

- 页 73

- 页 74

- 页 75

- 页 76

- 页 77

- 页 78

- 页 79

- 页 80

- 页 81

- 82: 新增页码2

- 页 83

- 页 84

- 页 85

- 页 86

- 页 87

- 页 88

- 页 89

- 页 90

- 页 91

- 页 92

- 页 93

- 页 94

- 页 95

- 页 96

- 页 97

- 页 98

- 页 99

- 页 100

- 页 101

- 页 102

- 页 103

- 页 104

- 页 105

- 页 106

- 页 107

- 页 108

- 页 109

- 页 110

- 页 111

- 页 112

- 页 113

- 页 114

- 页 115

- 页 116

- 页 117

- 页 118

- 页 119

- 页 120

- 页 121

- 页 122

- 页 123

- 页 124

- 页 125

- 页 126

- 页 127

- 页 128

- 页 129

- 页 130

- 页 131

- 页 132

- 页 133

- 页 134

- 页 135

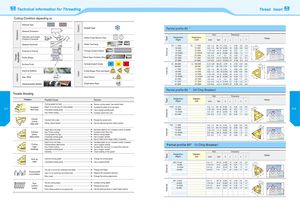

Technical information for Threading Thread Insert 01 Cutting Condition depending on Material Type c CDO Coolant Type Partial profile 60 oCD Material Dimension D OO CD Q- Pitch Dimensions I Diameter and LengthChipflow Character Holder Cross Section Area QCD. Designation Designation Picture(Right)(Left)(mm)(tpi)dLrxf Material Hardness £ Holder Overhang M 3ECDOverhang ER 11 - A60 EL 11 - A60 0.5-1.5 48-16 6.35 11 0.05 0.8 0.9 ~0V4External or Internalc-0 . 2oX Through Coolant Option ^j p, j 16 - A60CD 16 - A 60 0.5-1.5 48-16 9.525 16 0.05 0.8 0.9c16 - G6016 - G60- 1.753.014-89.525160.271.21.7 60M InternalCD16 - AG60X16 - AG600.5-3.048-89.525160.081.21.7LLU22 - N6022 - N603.5-5.07-512.7220.531.72.5 0 o‘o. Profile Shape Shank Type: CarbideQ. 27 - Q 60 27 - Q 60 - 5.5 6.0 4.5-4 15.875 27 0.64 2.1 3.127 - S 6027 - S 60- 5.58.0- 4.5415.875270.392.54.0 External < Surface Finish Carbide Implant Grade P M K IR 06 - A 60 IL 06 - A 60 0.5-1.25 48-20 3.97 6 0.04 0.6 0.6 08 -A60 08 - A 60 0.5-1.5 48-16 4.76 8 0.05 0.6 0.7 CDc 1 1 - A60 1 1 - A60 0,5-1.5 48-16 6.35 11 0.05 0.8 0.9 60S Internal Machine Stability -4 J Profile Shape: Pitch and Depth UQCDCDcCOccoMax. RPMRPMnNose RadiusCD CD 16 - A60 16 - A60 0.5-1.5 48-16 9.525 16 0.05 0.8 0.9 Lc16 -G6016 - G601.75-3.014-89.525160.161.21.716 - AG6016 - AG600.5 — 3.048-89.525160.051.21.722 - N6022 - N603.5-5.07-512.7220.301.72.5External 27 - Q60 27 - Q 60 5.5-6.0 4.5-4 15.875 27 0.30 1.8 2.7 Clamping System Stability Chipbreaker Style 27-S60 27 - S 60 - 5.5 8.0 4.5-4 15.875 27 0.39 2.5 4.0 Partial profile 60 0 (M Chip Breaker) Trouble Shooting Pitch Dimensions Problem Possible Cause Solution QCD. Designation(Right) Designation(Left) (mm) (tpi) d L r x f Picture Cutting speed too hight >- Reduce cutting speed/ use coated insert Increased Depth of cut too low/too many passes >- Increase the depth of cut per pass ERM 16 - A60 0.5— 1.5 48-16 9.525 16 0.05 0.8 0.9 017 flank wear Unsuitable carbide grade -> Use a coated carbide gradeInsu f ficient cooling>-Increase coolant flow rate 16 - G60 - 1.75 3.0 14-8 9.525 16 0.27 1.2 1.7 018CDc16 - AG600.5-3.048-89.525160.081.21.760KInternalCDx22- N603.5-5.07-512.7220.531.72.5L LU Uneven Incorrect helix angle -> Choose the correct shim External cutting edge wear Wrong infeed method -> Use the Alternating Flank Infeed method IRM 11 - A 60 0.5— 1.5 48-16 6.35 11 0.08 0.8 0.9 Depth olf cut too large — Decrease depth of cut/ increase number of passes 16 - A 60 - 0.5 1.5 48-16 9.525 16 0.08 0.8 0.9 InternalCDc16 - G601.75-3.014-89.525160.121.21.760S Extreme Insu f ficient cooling >- Increase coolant flow rate CD 16 - AG60 0.5-3.0 48-8 9.525 16 0.08 1.2 1.7 plastic Cutting speed too high - >- Reduce cutting speed c 22- N60 - 3.5 5.0 7-5 12.7 22 0.30 1.7 2.5 deformation Unsuitable carbide grade -> Use a tougher carbide Nose radius too small — -> Use an insert with a larger radius, if possible External Depth of cut too large -> Decrease depth of cut/ increase number of passes. Cutting Extreme plastic deformation -> Use a tougher carbide Partial profile 60° (U Chip Breaker) edge Insu f ficient cooling -> Increase flow rate and/ or correct flow direction breakage Unsuitable carbide grade — -> Use a tougher carbide Instability -> Check stability of the system Pitch Dimensions QCD. Designation(Right) Designation(Left) (mm) (tpi) d L r x f Picture Built - up Incorrect cutting speed - >- Change the cutting speed edge Unsuitable carbide grade >- Use a coated carbide ERU 16-A60 0 -.5 1.5 48-16 9.525 16 0.08 0.8 0.9 16-G60 1. -75 3.0 14-8 9.525 16 0.27 1.2 1.7 CDc 16-AG60 0.5-3.0 48-8 9.525 16 0.08 1.2 1.7 Interna60° The tool is not at the workpiece axis height >- Change tool height CD 22-N60 - 3.5 5.0 7-5 12.7 22 0.53 1.7 2.5 Thread profileis too shallowInsert is not machining the thread crest— -> Measure the workpiece diameter XLU L Worn insert -> Change the cutting edge sooner External IRU 16-A60 - 0.5 1.5 48-16 9.525 16 0.08 0.8 0.9 Poor Too low cutting speed >- Increase cutting speed 16-G60 1. -75 3.0 14-8 9.525 16 0.12 1.2 1.7 r -X Internal surface Wrong shim ->- Choose correct shim CDc 16-AG60 0. -5 3.0 48-8 9.525 16 0.08 1.2 1.7 60° quality Flank infeed method is not appropriate >- Use the alternate flank or radial infeed method CD 22-N60 3.5-5.0 7-5 12.7 22 0.30 1.7 2.5c External

Каталог TooTool техническая информация 1

Каталог TooTool техническая информация 1 Каталог TooTool монолитные фрезы

Каталог TooTool монолитные фрезы Каталог TooTool техническая информация 2

Каталог TooTool техническая информация 2