Общий каталог TooTool - страница 119

Навигация

- 页 1

- 页 2

- 页 3

- 页 4

- 页 5

- 页 6

- 页 7

- 页 8

- 页 9

- 页 10

- 页 11

- 页 12

- 页 13

- 页 14

- 页 15

- 页 16

- 页 17

- 页 18

- 页 19

- 页 20

- 页 21

- 页 22

- 页 23

- 页 24

- 页 25

- 页 26

- 页 27

- 页 28

- 页 29

- 页 30

- 页 31

- 页 32

- 页 33

- 页 34

- 页 35

- 页 36

- 页 37

- 页 38

- 页 39

- 页 40

- 页 41

- 页 42

- 页 43

- 页 44

- 页 45

- 页 46

- 页 47

- 页 48

- 页 49

- 页 50

- 页 51

- 页 52

- 页 53

- 页 54

- 页 55

- 页 56

- 页 57

- 页 58

- 页 59

- 页 60

- 页 61

- 页 62

- 页 63

- 页 64

- 页 65

- 页 66

- 页 67

- 页 68

- 页 69

- 页 70

- 页 71

- 页 72

- 页 73

- 页 74

- 页 75

- 页 76

- 页 77

- 页 78

- 页 79

- 页 80

- 页 81

- 82: 新增页码2

- 页 83

- 页 84

- 页 85

- 页 86

- 页 87

- 页 88

- 页 89

- 页 90

- 页 91

- 页 92

- 页 93

- 页 94

- 页 95

- 页 96

- 页 97

- 页 98

- 页 99

- 页 100

- 页 101

- 页 102

- 页 103

- 页 104

- 页 105

- 页 106

- 页 107

- 页 108

- 页 109

- 页 110

- 页 111

- 页 112

- 页 113

- 页 114

- 页 115

- 页 116

- 页 117

- 页 118

- 页 119

- 页 120

- 页 121

- 页 122

- 页 123

- 页 124

- 页 125

- 页 126

- 页 127

- 页 128

- 页 129

- 页 130

- 页 131

- 页 132

- 页 133

- 页 134

- 页 135

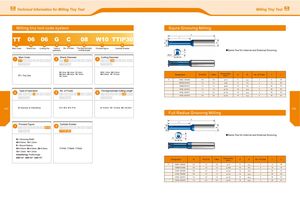

Technical Information for Milling Tiny Tool Milling Tiny Tool 01 Milling tiny tool code system Squre Grooving Milling L Main code Shank Dia Cutting Dia Type of No. of flutes The Approximate Process figure Carbide Gradesoperationcutting length •Same Tool for Internal and External Grooving Main Code Shank Diameter Cutting Diameter 03: 3mm 04: 4mm 05: 5mm 015: 1,5mm 05: 5.0mm TT = Tiny Tool 06: 6mm 08: 8mm 10: 10mm 06: 6.0mm 10: 10.0mm12: 12mm Designation W ±0.02 T Max. Groove Dia.(min.) d D No. of Flutes I L TT 0606G C08 W08 0.8 0.8 cp > 6 6 6.0 3 8 58 08078G D10 W10 1.0 1.2 q> >8 8 7.8 4 10 64 10098G D20 W12 1.2 1.4 cp >10 10 9.8 4 20 73 1616G E30 W14 1.4 1.8 cp > 16 16 16.0 5 30 101 Type of Operation No. of Flutes The Approximate Cutting Length m 1616G E40 W17 1.7 2.0 cp > 16 16 16.0 5 40 101 1616G E45 W19 2.0 2.2 cp > 16 16 16.0 5 45 101 233 G: Grooving C: Chamfering C=3 D=4 E=5 F=6 8 = 8.0mm 10 = 10.0mm 40 = 40.0mm 234 Full Radius Grooving Milling L Process Figure Carbide Grades iiiacm •Same Tool for Internal and External Grooving W = Grooving Width 08=0.8mm 10 = 1.0mm R = Round Radius 05=0.5mm 06 = 0.6 mm 09=0.9mm TTIP30 TTIM45 TTIS30 10=1.0mm 15=1.5mm Chamfering: Profile Angle A90=90° A60=60° A45=45° Designation R W ±0.02 T Max. Groove Dia.(min.) d D No. of Flutes I L TT 0606G C08 R05 0.5 1.0 0.8 cp > 6 6 6.0 3 8 58 10088GD16 R05 0.5 1.0 1.0 cp > 8.8 10 8.8 4 16 73 1010G D20 R06 0.6 1.2 1.0 cp > 10 10 10.0 4 20 73 1212G D30 R09 0.9 1.8 1.4 cp > 12 12 12.0 4 30 84 1616G E40 R10 1.0 2.0 1.6 cp > 16 16 16.0 5 40 101 1616G E40 R15 1.5 3.0 2.2 cp > 16 16 16.0 5 40 101

Каталог TooTool техническая информация 1

Каталог TooTool техническая информация 1 Каталог TooTool монолитные фрезы

Каталог TooTool монолитные фрезы Каталог TooTool техническая информация 2

Каталог TooTool техническая информация 2