Общий каталог TooTool - страница 9

Навигация

- 页 1

- 页 2

- 页 3

- 页 4

- 页 5

- 页 6

- 页 7

- 页 8

- 页 9

- 页 10

- 页 11

- 页 12

- 页 13

- 页 14

- 页 15

- 页 16

- 页 17

- 页 18

- 页 19

- 页 20

- 页 21

- 页 22

- 页 23

- 页 24

- 页 25

- 页 26

- 页 27

- 页 28

- 页 29

- 页 30

- 页 31

- 页 32

- 页 33

- 页 34

- 页 35

- 页 36

- 页 37

- 页 38

- 页 39

- 页 40

- 页 41

- 页 42

- 页 43

- 页 44

- 页 45

- 页 46

- 页 47

- 页 48

- 页 49

- 页 50

- 页 51

- 页 52

- 页 53

- 页 54

- 页 55

- 页 56

- 页 57

- 页 58

- 页 59

- 页 60

- 页 61

- 页 62

- 页 63

- 页 64

- 页 65

- 页 66

- 页 67

- 页 68

- 页 69

- 页 70

- 页 71

- 页 72

- 页 73

- 页 74

- 页 75

- 页 76

- 页 77

- 页 78

- 页 79

- 页 80

- 页 81

- 82: 新增页码2

- 页 83

- 页 84

- 页 85

- 页 86

- 页 87

- 页 88

- 页 89

- 页 90

- 页 91

- 页 92

- 页 93

- 页 94

- 页 95

- 页 96

- 页 97

- 页 98

- 页 99

- 页 100

- 页 101

- 页 102

- 页 103

- 页 104

- 页 105

- 页 106

- 页 107

- 页 108

- 页 109

- 页 110

- 页 111

- 页 112

- 页 113

- 页 114

- 页 115

- 页 116

- 页 117

- 页 118

- 页 119

- 页 120

- 页 121

- 页 122

- 页 123

- 页 124

- 页 125

- 页 126

- 页 127

- 页 128

- 页 129

- 页 130

- 页 131

- 页 132

- 页 133

- 页 134

- 页 135

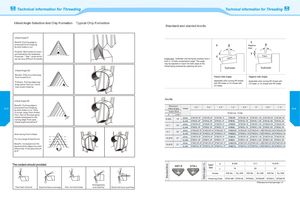

Technical information for Threading Technical information for Threading Infeed Angle Selection And Chip Formation Typical Chip Formation Standard and slanted Anvils Infeed Angle 0° Benefit:Cutting edge is Y protected from chipping Negative by both sides in cut. Helix Problem :Both sides of insert are heated by the wokpiece. Produces " Vee " chips which Insert can be very difficult to handle. TTOOLTEC toolholder and boring bar pockets have a built-in 1.5 helix compensation angle. This angle may be adjusted to match the helix angle of the thread being produced by replacing the anvil. Toolholder Toolholder Infeed Angle 30° Benefit :Chip is curled away from thread form. Positive Helix Angles Negative Helix Angles Problem: Trailing edge maydrag rather than cut, whichmay cause chipping. Applicable when turning RH thread Applicable when turning RH thread withwith RH holder or LH thread withLH holder or LH thread with RH holder.LH holder. Anvils Infeed Angle 29° Benefit: Cutting edge is013protected from chippingby both sides in cut. Chip Resultant 4.5 ° 3.5 0 2.5 0 1.5 ° 0.5 0 0 0 - 0.5 0 - 1.5 0Helix AngleHolder014 is curled away from thread Insert Size Ordering Code from. Part of the heat gene- d Lmm ratedis dissipated to thetrailing edge.Final passinfeed angle should be 0° 9.525 16 ER/NL STM16R -3P STM16R-2P S T M 1 6 R -1P STM16R STM16R-1N STM16R-1.5N STM16R-2N STM16R-3NEL/NRSTM16L-3PSTM16L-2PSTM16L-1PSTM16LSTM16L-1NSTM16L-1.5NSTM16L-2NSTM16L-3N 12.7 22 ER/NL STM22R-3P STM22R-2P STM22R-1P STM22R STM22R-1N STM22R-1.5N STM22R-2N STM22R-3N EL/NR STM22L-3P STM22L-2P STM22L-1P STM22L STM22L-1N STM22L-1.5N STM22L-2N STM22L-3N 12.7 22 ER/NL STM22UR-3P STM22UR-2P S T M 2 2U R -1P STM22UR STM22UR-1N STM22UR-1.5N STM22UR-2N STM22UR-3N Alternating Flank Infeed EL/NR STM22UL-3P STM22UL-2P STM22UL-1P STM22UL S T M2 2 U L-1N STM22UL-1.5N STM22UL-2N STM22UL-3N ER/NL STM27R-3P STM27R-2P STM27R-1P STM27R STM27R-1N STM27R-1.5N STM27R-2N STM27R-3N For very large thread forms 15.875 27 EL/NR STM27L-3P STM27L-2P STM27L-1P STM27L STM27L-1N STM27L-1.5N STM27L-2N STM27L-3N Benefit: Increased tool life ER/NL STM27UR-3P STM27UR-2P S T M 2 7 U R -1P STM27UR STM27UR-1N STM27UR-1.5N STM27UR-2N STM27UR-3N15.87527 because both edges are used EL/NR STM27UL-3P STM27UL-2P STM27UL-1P STM27UL S T M2 7 U L -1N STM27UL-1.5N STM27UL-2N STM27UL-3N effectively. Final pass should be 0° The coolant should providedv?= L/ _cE cn ~o LO Insert d 9.525 12.7 15.875CDSizeL162227CD£03CT3c03XHolderER/NLEL/NRER/NLEL/NRER/NLEL/NR =.: iiiiii!!!!!: ::::::::i1 03CO Cl)X Ordering Code STM16R STM16L STM22L STM22R STM27L STM27R A f\ l\ ^Standard anvil has lead angle 1.5° Homogeneity Fast heat removal Good surface coverage Non - corrosiveness and stability Good lubricant qualities

Каталог TooTool техническая информация 1

Каталог TooTool техническая информация 1 Каталог TooTool монолитные фрезы

Каталог TooTool монолитные фрезы Каталог TooTool техническая информация 2

Каталог TooTool техническая информация 2