Общий каталог TooTool - страница 110

Навигация

- 页 1

- 页 2

- 页 3

- 页 4

- 页 5

- 页 6

- 页 7

- 页 8

- 页 9

- 页 10

- 页 11

- 页 12

- 页 13

- 页 14

- 页 15

- 页 16

- 页 17

- 页 18

- 页 19

- 页 20

- 页 21

- 页 22

- 页 23

- 页 24

- 页 25

- 页 26

- 页 27

- 页 28

- 页 29

- 页 30

- 页 31

- 页 32

- 页 33

- 页 34

- 页 35

- 页 36

- 页 37

- 页 38

- 页 39

- 页 40

- 页 41

- 页 42

- 页 43

- 页 44

- 页 45

- 页 46

- 页 47

- 页 48

- 页 49

- 页 50

- 页 51

- 页 52

- 页 53

- 页 54

- 页 55

- 页 56

- 页 57

- 页 58

- 页 59

- 页 60

- 页 61

- 页 62

- 页 63

- 页 64

- 页 65

- 页 66

- 页 67

- 页 68

- 页 69

- 页 70

- 页 71

- 页 72

- 页 73

- 页 74

- 页 75

- 页 76

- 页 77

- 页 78

- 页 79

- 页 80

- 页 81

- 82: 新增页码2

- 页 83

- 页 84

- 页 85

- 页 86

- 页 87

- 页 88

- 页 89

- 页 90

- 页 91

- 页 92

- 页 93

- 页 94

- 页 95

- 页 96

- 页 97

- 页 98

- 页 99

- 页 100

- 页 101

- 页 102

- 页 103

- 页 104

- 页 105

- 页 106

- 页 107

- 页 108

- 页 109

- 页 110

- 页 111

- 页 112

- 页 113

- 页 114

- 页 115

- 页 116

- 页 117

- 页 118

- 页 119

- 页 120

- 页 121

- 页 122

- 页 123

- 页 124

- 页 125

- 页 126

- 页 127

- 页 128

- 页 129

- 页 130

- 页 131

- 页 132

- 页 133

- 页 134

- 页 135

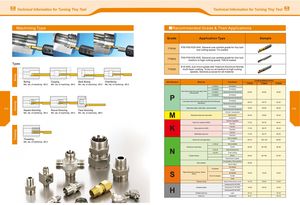

Technical Information for Turning Tiny Tool Technical Information for Turning Tiny Tool H Machining Type Recommended Grade & Their Applications Grade Application Type Sample TTIP 30 P30-P50 K25-K40, General use carbide grade for tiny toollow cutting speed, Tin coated TTIM45 P20-P30 K 20-K30, General use carbide grade for tiny toolmedium to high cutting speed, TiALN coated K 10-K20, sub-micro grade with Titanium Aluminum Nitride TTIS30 multi-layer coating. To be run at medium to high cutting speeds, General purpose for all material. Boring Copying Back Boring Chamfering Cutting Speed m/minISO StandardMaterialCondition Min. dia. of machining : 03.2 Min. dia. of machining : 04.2 Min. dia. of machining : 03.2 Min. dia. of machining : 04.2 TTIP30 TTIM45 TTIS30 <0.25%C Annealed >0.25%C Annealed Non-Alloy steel and cast steel, freecutting steel <0.55%C Quenched and Tempered 25-50 30-80 30-60 P >0.55%C AnnealedQuenched and Tempered O)C Low alloy steel and cast steel (less than 5% alloying Annealedelements)Quenched and Tempered20-25 50-70 24-30 > O Annealed 215 Oo Square Grooving Round Grooving Face Grooving High alloy steel, cast steel , and tool steel 18-20 30-50 22-24Quenched and Tempered216 Min. dia. of machining : 03.2 Min. dia. of machining : 03.2 Min. dia. of machining : 06.0 M Ferritic / martensiticStainless steel and cast steelMartensitic25-3040-6030-42 Austenitic Ferritic / pearlitic Cast iron nodular (GGG) 17-23 50-70 30-42 Pearlitic Ferritic Grey cast iron (GG) 17-23 50-70 30-42 CD Pearlitic C Ferritic "O03_0C Threading Malleable cast iron 17-23 50-70 30-42PearliticNot cureableAluminum-wrought alloy50-70100-15060-84 Min. dia. of machining : 03.3 Cured <12% Si Not cureable Aluminum-cast alloy Cured 30-40 60-100 36-48 >12% Si High temperature >1% Pb Free cutting Copper alloys Brass 22-25 60-100 24-30 Electrolytic copper Duroplatics, fiber plastics Non metalic 35-45 Hard rubber Annealed Fe based s High temperature alloys, Superalloys Ni or Co based CuredAnnealedCured 15-20 15-20 18-24 Cast Titanium alloy Alpha+beta alloys cured 12-18 40-50 15-20 Hardened 45-50 HRC H Hardend steel Hardened 51-55 HRC 15-20 20-45 18-24Hardened 56-62 HRC Chilled cast iron cast 10-14 12-16 Cast iron Hardened 8-12 10-14

Каталог TooTool техническая информация 1

Каталог TooTool техническая информация 1 Каталог TooTool монолитные фрезы

Каталог TooTool монолитные фрезы Каталог TooTool техническая информация 2

Каталог TooTool техническая информация 2