Общий каталог TooTool - страница 48

Навигация

- 页 1

- 页 2

- 页 3

- 页 4

- 页 5

- 页 6

- 页 7

- 页 8

- 页 9

- 页 10

- 页 11

- 页 12

- 页 13

- 页 14

- 页 15

- 页 16

- 页 17

- 页 18

- 页 19

- 页 20

- 页 21

- 页 22

- 页 23

- 页 24

- 页 25

- 页 26

- 页 27

- 页 28

- 页 29

- 页 30

- 页 31

- 页 32

- 页 33

- 页 34

- 页 35

- 页 36

- 页 37

- 页 38

- 页 39

- 页 40

- 页 41

- 页 42

- 页 43

- 页 44

- 页 45

- 页 46

- 页 47

- 页 48

- 页 49

- 页 50

- 页 51

- 页 52

- 页 53

- 页 54

- 页 55

- 页 56

- 页 57

- 页 58

- 页 59

- 页 60

- 页 61

- 页 62

- 页 63

- 页 64

- 页 65

- 页 66

- 页 67

- 页 68

- 页 69

- 页 70

- 页 71

- 页 72

- 页 73

- 页 74

- 页 75

- 页 76

- 页 77

- 页 78

- 页 79

- 页 80

- 页 81

- 82: 新增页码2

- 页 83

- 页 84

- 页 85

- 页 86

- 页 87

- 页 88

- 页 89

- 页 90

- 页 91

- 页 92

- 页 93

- 页 94

- 页 95

- 页 96

- 页 97

- 页 98

- 页 99

- 页 100

- 页 101

- 页 102

- 页 103

- 页 104

- 页 105

- 页 106

- 页 107

- 页 108

- 页 109

- 页 110

- 页 111

- 页 112

- 页 113

- 页 114

- 页 115

- 页 116

- 页 117

- 页 118

- 页 119

- 页 120

- 页 121

- 页 122

- 页 123

- 页 124

- 页 125

- 页 126

- 页 127

- 页 128

- 页 129

- 页 130

- 页 131

- 页 132

- 页 133

- 页 134

- 页 135

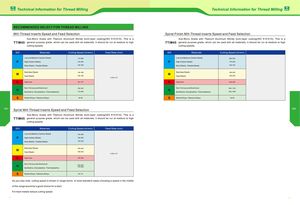

Technical Information for Thread Milling Technical Information for Thread Milling RECOMMENDED SELECT FORTHREAD MILLING Mill-Thread Inserts Speed and Feed Selection Spiral Finish Mill-Thread Inserts Speed and Feed Selection Sub-Micro Grade with Titanium Aluminum Nitride multi-layer coating(ISO K10-K10). This is a Sub-Micro Grade with Titanium Aluminum Nitride multi-layer coating(ISO K10-K10). This is a TTIM45 general purpose grade, which can be used with all materials; It should be run at medium to high TTIM45 general purpose grade, which can be used with all materials; It should be run at medium to high cutting speeds. cutting speeds. ISO Materials Cutting Speed (m/min) Feed Rate (mm) ISO Materials Cutting Speed (m/min) Low and Medium Carbon Steels 115-280 Low and Medium Carbon Steels 200-330 P High Carbon Steels 130-200 P High Carbon Steels 170-235 Alloy Steels, Treated Steels 105-180 Alloy Steels, Treated Steels 100-195 Stainless Steels 130-190 Stainless Steels 180-230 M M Cast Steels 150-190 Cast Steels 180-230 0.05-0.15 Cast Iron 80-170 Cast Iron 200-350 Non-Ferrous and Aluminum 180-340 Non-Ferrous and Aluminum 500-1100 N N Synthetics, Duroplastics, Thermoplastics 115-460 Synthetics, Duroplastics, Thermoplastics 400-1500 s Nickel Alloys, Titanium Alloys 25-90 s Nickel Alloys, Titanium Alloys 30-55 091 Spiral Mill-Thread Inserts Speed and Feed Selection 092 Sub-Micro Grade with Titanium Aluminum Nitride multi-layer coating(ISO K10-K10). This is a TTIM45 general purpose grade, which can be used with all materials; It should be run at medium to high cutting speeds. ISO Materials Cutting Speed (m/min) Feed Rate (mm) Low and Medium Carbon Steels 145-360 P High Carbon Steels 165-255 Alloy Steels, Treated Steels 135-230 Stainless Steels 165-245 M Cast Steels 190-245 0.05-0.15 Cast Iron 100-220 Non-Ferrous and Aluminum N Synthetics, Duroplastics, Thermoplastics 230-440145-590 s Nickel Alloys, Titanium Alloys 30-115 As you may note, cutting speed is shown in range terms. In most standard cases choosing a speed in the middle of the range would be a good choice for a start. For hard metals reduce cutting speed.

Каталог TooTool техническая информация 1

Каталог TooTool техническая информация 1 Каталог TooTool монолитные фрезы

Каталог TooTool монолитные фрезы Каталог TooTool техническая информация 2

Каталог TooTool техническая информация 2