Каталог Sumitomo пластины с алмазными вставками Sumidia - страница 47

Навигация

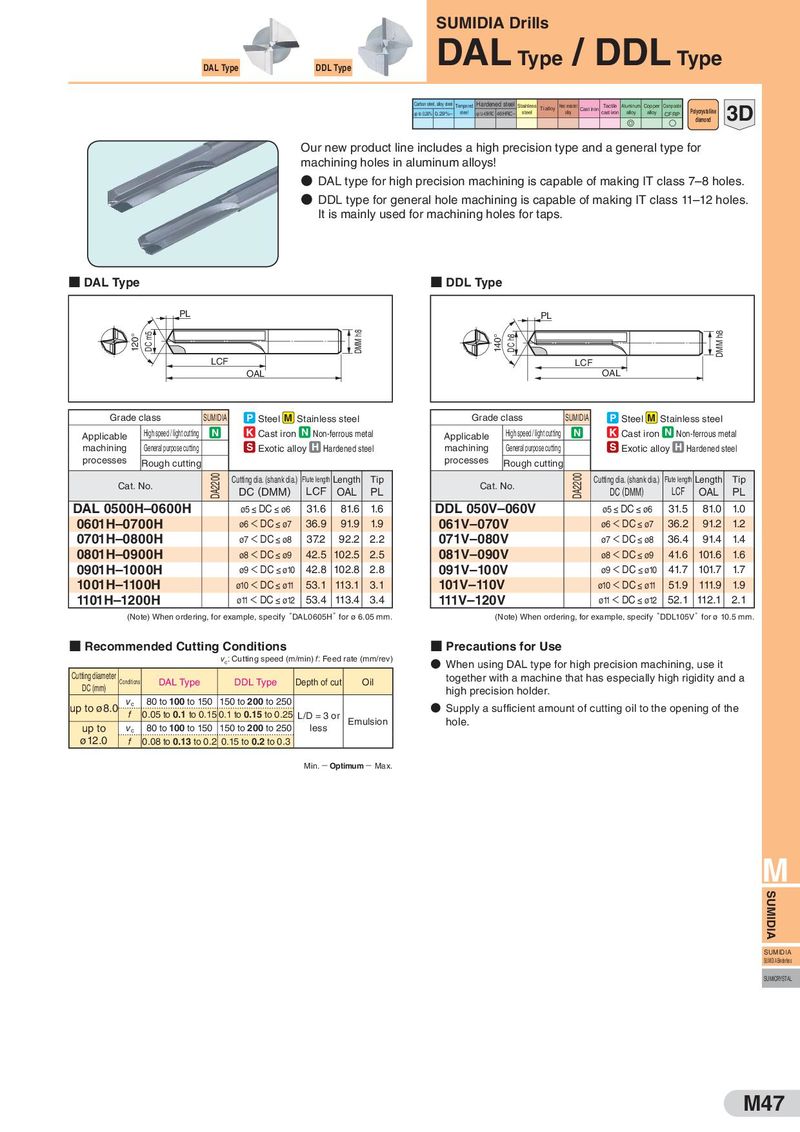

SUMIDIA Drills DAL Type DDL Type DAL Type / DDL Type Carbon steel, alloy steel Tempered Hardened steel Stainless Ti alloy Heat resistant Cast iron Tactile Aluminum Copper Composite 3D up to 0.28% 0.29%– steel up to 45HRC 46HRC– steel alloy cast iron alloy alloy CFRP Polycrystalline G S diamond Our new product line includes a high precision type and a general type for machining holes in aluminum alloys! ● DAL type for high precision machining is capable of making IT class 7–8 holes. ● DDL type for general hole machining is capable of making IT class 11–12 holes. It is mainly used for machining holes for taps. ■ DAL Type ■ DDL Type PL PL 120° DC m5 DMM h8 140° DC h8 DMM h8 LCF LCF OAL OAL Grade class SUMIDIA P Steel M Stainless steel Grade class SUMIDIA P Steel M Stainless steel Applicable High speed / light cutting N K Cast iron N Non-ferrous metal Applicable High speed / light cutting N K Cast iron N Non-ferrous metal machining General purpose cutting S Exotic alloy H Hardened steel machining General purpose cutting S Exotic alloy H Hardened steel processes Rough cutting processes Rough cutting Cat. No. DA2200 Cutting dia. (shank dia.) Flute length Length Tip Cat. No. DA2200 Cutting dia. (shank dia.) Flute length Length Tip DC (DMM) LCF OAL PL DC (DMM) LCF OAL PL DAL 0500H–0600H ø5 ≤ DC ≤ ø6 31.6 81.6 1.6 DDL 050V–060V ø5 ≤ DC ≤ ø6 31.5 81.0 1.0 0601H–0700H ø6 < DC ≤ ø7 36.9 91.9 1.9 061V–070V ø6 < DC ≤ ø7 36.2 91.2 1.2 0701H–0800H ø7 < DC ≤ ø8 37.2 92.2 2.2 071V–080V ø7 < DC ≤ ø8 36.4 91.4 1.4 0801H–0900H ø8 < DC ≤ ø9 42.5 102.5 2.5 081V–090V ø8 < DC ≤ ø9 41.6 101.6 1.6 0901H–1000H ø9 < DC ≤ ø10 42.8 102.8 2.8 091V–100V ø9 < DC ≤ ø10 41.7 101.7 1.7 1001H–1100H ø10 < DC ≤ ø11 53.1 113.1 3.1 101V–110V ø10 < DC ≤ ø11 51.9 111.9 1.9 1101H–1200H ø11 < DC ≤ ø12 53.4 113.4 3.4 111V–120V ø11 < DC ≤ ø12 52.1 112.1 2.1 (Note) When ordering, for example, specify DAL0605H for ø 6.05 mm. (Note) When ordering, for example, specify DDL105V for ø 10.5 mm. ■ Recommended Cutting Conditions ■ Precautions for Use vc: Cutting speed (m/min) f: Feed rate (mm/rev) ● When using DAL type for high precision machining, use it Cutting diameter Conditions DAL Type DDL Type Depth of cut Oil together with a machine that has especially high rigidity and a DC (mm) high precision holder. up to ø8.0 vc 80 to 100 to 150 150 to 200 to 250 ● Supply a sufficient amount of cutting oil to the opening of the f 0.05 to 0.1 to 0.15 0.1 to 0.15 to 0.25 L/D = 3 or Emulsion hole. up to vc 80 to 100 to 150 150 to 200 to 250 less ø12.0 f 0.08 to 0.13 to 0.2 0.15 to 0.2 to 0.3 Min. − Optimum − Max. M SUMIDIA SUMIDIA SUMIDIA Binderless SUMICRYSTAL M47

Каталог Sumitomo токарные резцы (державки) для внутреннего точения

Каталог Sumitomo токарные резцы (державки) для внутреннего точения Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Техническая информация Sumitomo

Техническая информация Sumitomo Каталог Sumitomo модульные системы для револьверных головок токарных станков

Каталог Sumitomo модульные системы для револьверных головок токарных станков Каталог Sumitomo твердосплавные заготовки

Каталог Sumitomo твердосплавные заготовки Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами