Каталог Sumitomo пластины с алмазными вставками Sumidia - страница 31

Навигация

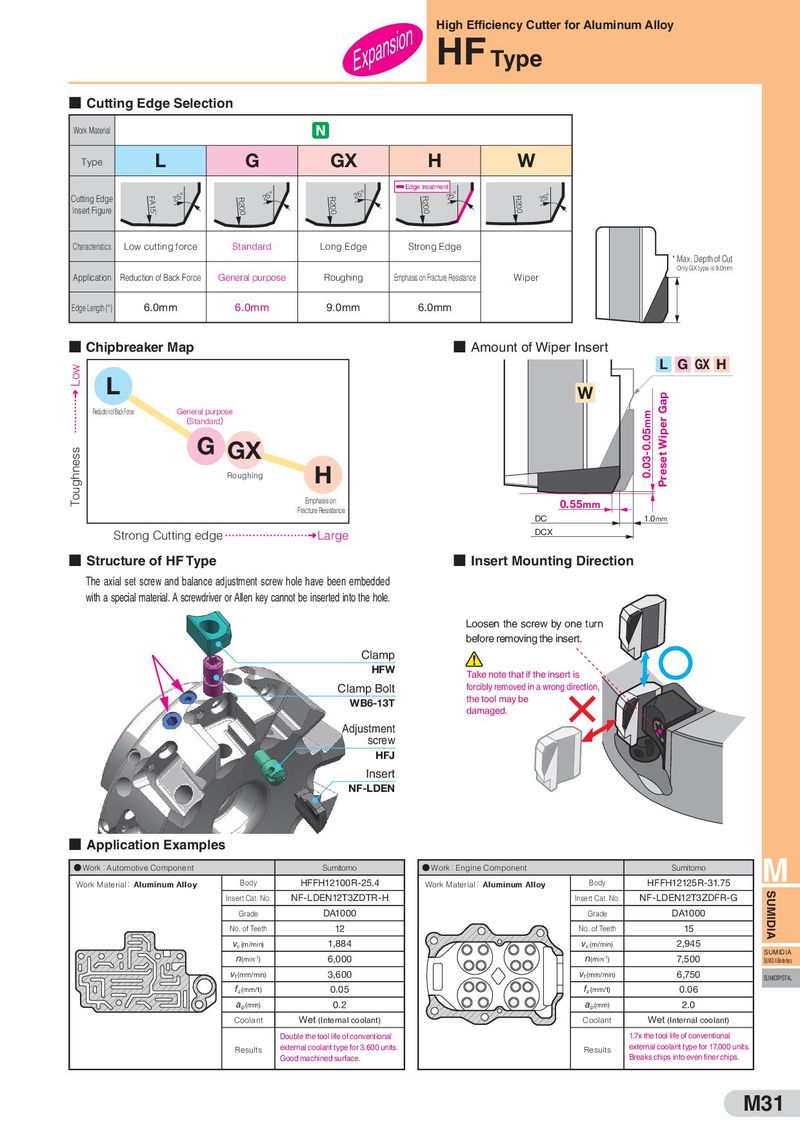

Expansion High Efficiency Cutter for Aluminum Alloy HF Type ■ Cutting Edge Selection Work Material Type L G GX H W 25° Edge treatment Cutting Edge FA15’ 25° R200 25° R200 R200 25° R200 25° Insert Figure Characteristics Low cutting force Standard Long Edge Strong Edge * Max. Depth of Cut Only GX type is 9.0mm Application Reduction of Back Force General purpose Roughing Emphasis on Fracture Resistance Wiper Edge Length (*) 6.0mm 6.0mm 9.0mm 6.0mm ■ Chipbreaker Map ■ Amount of Wiper Insert Low L G GX H L W Preset Wiper Gap Reduction of Back Force General purpose 0.03-0.05mm (Standard) Toughness G GX Roughing H Emphasis on 0.55mm Fracture Resistance DC 1.0mm Strong Cutting edge Large DCX ■ Structure of HF Type ■ Insert Mounting Direction The axial set screw and balance adjustment screw hole have been embedded with a special material. A screwdriver or Allen key cannot be inserted into the hole. Loosen the screw by one turn before removing the insert. Clamp HFW Take note that if the insert is Clamp Bolt forcibly removed in a wrong direction, WB6-13T the tool may be damaged. Adjustment screw HFJ Insert NF-LDEN ■ Application Examples ● Work:Automotive Component Sumitomo ● Work:Engine Component Sumitomo M Work Material:Aluminum Alloy Body HFFH12100R-25.4 Work Material:Aluminum Alloy Body HFFH12125R-31.75 Insert Cat. No. NF-LDEN12T3ZDTR-H Insert Cat. No. NF-LDEN12T3ZDFR-G SUMIDIA Grade DA1000 Grade DA1000 No. of Teeth 12 No. of Teeth 15 vc (m/min) 1,884 vc (m/min) 2,945 n(min-1) 6,000 n(min-1) 7,500 SUMIDIA SUMIDIA Binderless vf (mm/min) 3,600 vf (mm/min) 6,750 SUMICRYSTAL fz (mm/t) 0.05 fz (mm/t) 0.06 ap (mm) 0.2 ap (mm) 2.0 Coolant Wet (Internal coolant) Coolant Wet (Internal coolant) Double the tool life of conventional 1.7x the tool life of conventional Results external coolant type for 3,600 units. Results external coolant type for 17,000 units. Good machined surface. Breaks chips into even finer chips. M31

Каталог Sumitomo токарные резцы (державки) для внутреннего точения

Каталог Sumitomo токарные резцы (державки) для внутреннего точения Каталог Sumitomo микроинструмент

Каталог Sumitomo микроинструмент Техническая информация Sumitomo

Техническая информация Sumitomo Каталог Sumitomo модульные системы для револьверных головок токарных станков

Каталог Sumitomo модульные системы для револьверных головок токарных станков Каталог Sumitomo твердосплавные заготовки

Каталог Sumitomo твердосплавные заготовки Каталог Sumitomo фрезы со сменными пластинами

Каталог Sumitomo фрезы со сменными пластинами